High-temperature and high-pressure uninterrupted soaking rotation oil washing device and method

A high-temperature, high-pressure, uninterrupted technology, applied in the preparation of test samples, etc., can solve the problems of reduced oil washing efficiency, low safety performance, and low degree of automation, so as to improve cleaning efficiency and effect, save oil washing time, and improve The effect of oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

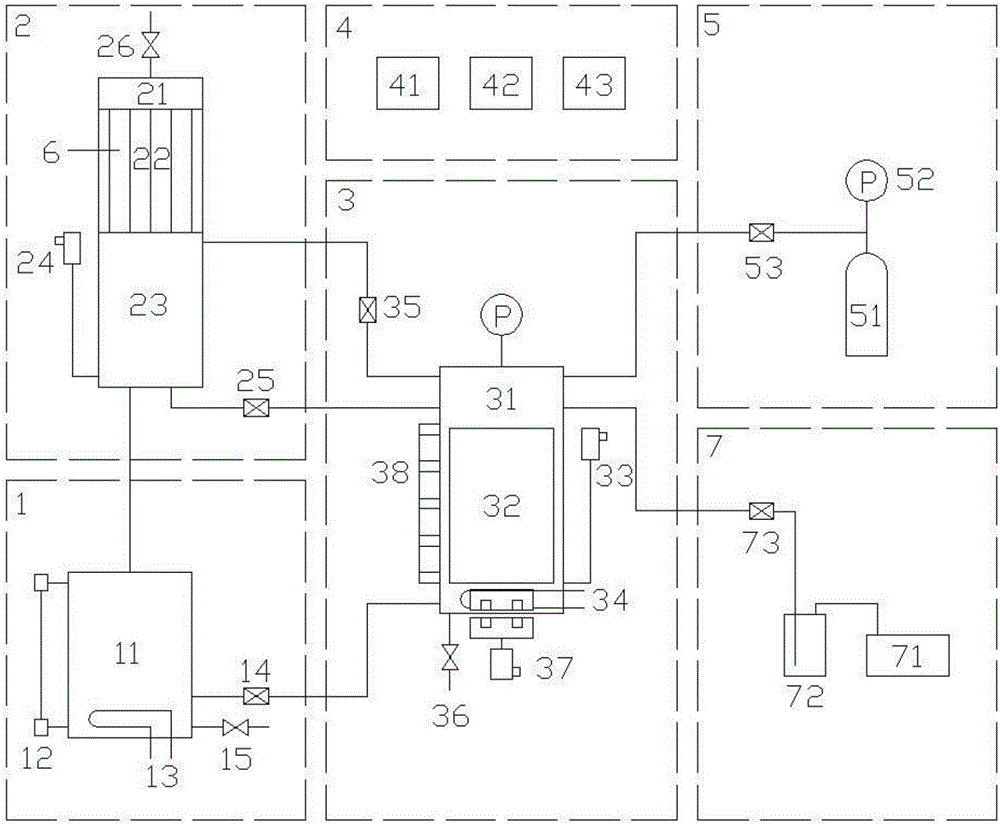

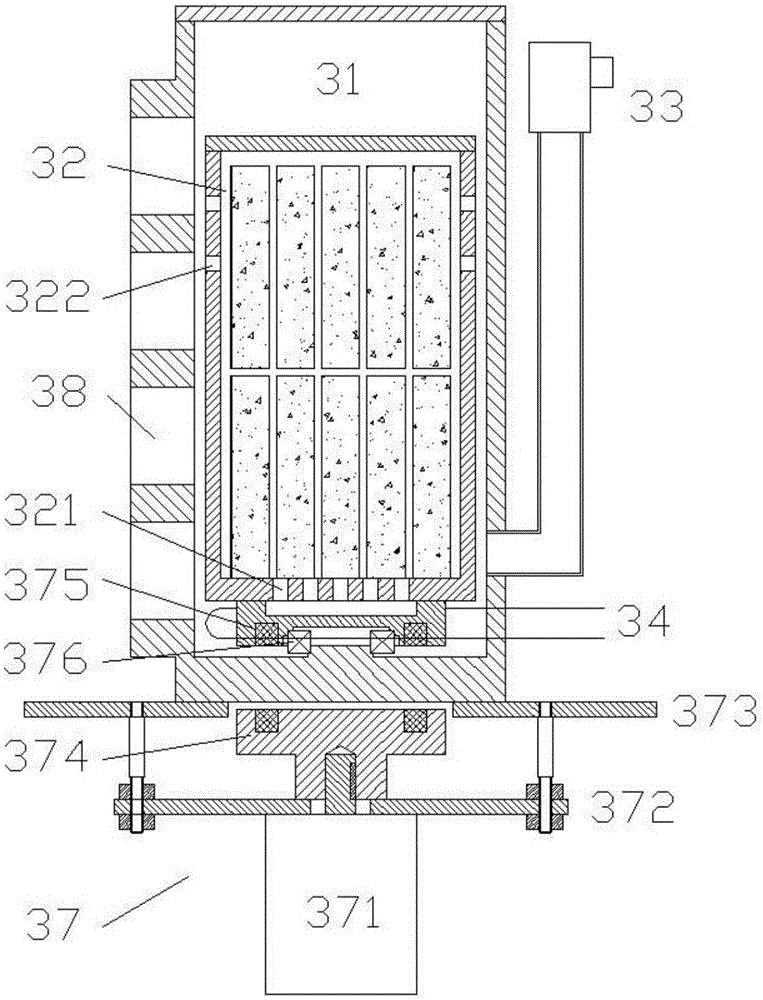

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, first refer to the attached figure 1 , 2 and 3 illustrate the invention.

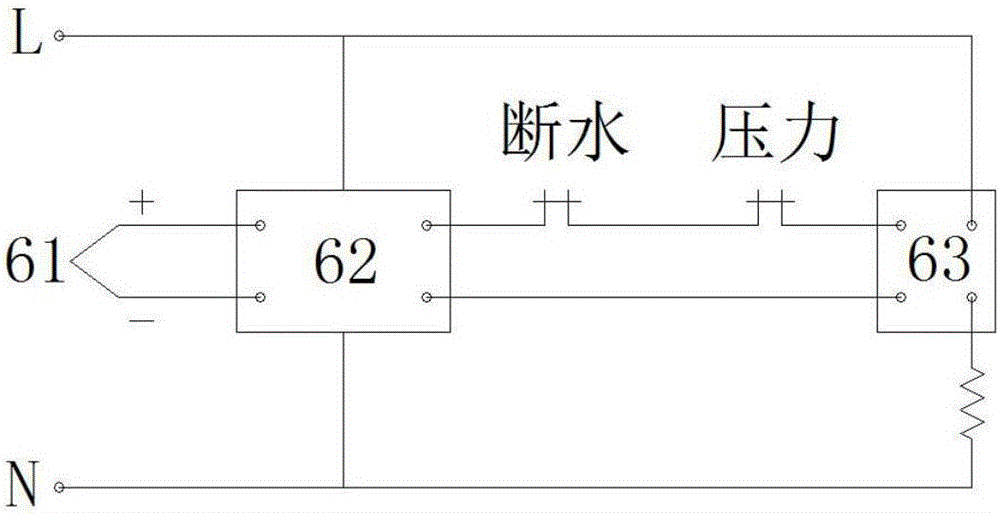

[0041] Such as figure 1As shown, the high temperature and high pressure uninterrupted immersion rotary core oil washing instrument provided by the present invention includes a solvent tank 1, a condensation tank 2, a core cleaning tank 3, a control system 4 and a core cleaning tank pressurization system 5. The solvent tank 1 is composed of a solvent chamber 11, a first liquid level indicator 12, a first heating pipe 13, a first pneumatic valve 14 and a first manual valve 15; the first liquid level indicator 12 is installed on the outside of the left side wall of the solvent chamber 11 , the first heating tube 13 is installed in the inner bottom of the solvent chamber 11, the first pneumatic valve 14 is connected to the solvent chamber 11 right side wall by a pipeline, and the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com