A large-scale rocket engine and support overall flip fixture

A large-scale rocket and flipping fixture technology, which is applied in engine testing, vibration testing, machine/structural component testing, etc., can solve the problems of no flipping fixture and method flipping, and achieve low cost, strong operability, and guaranteed safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

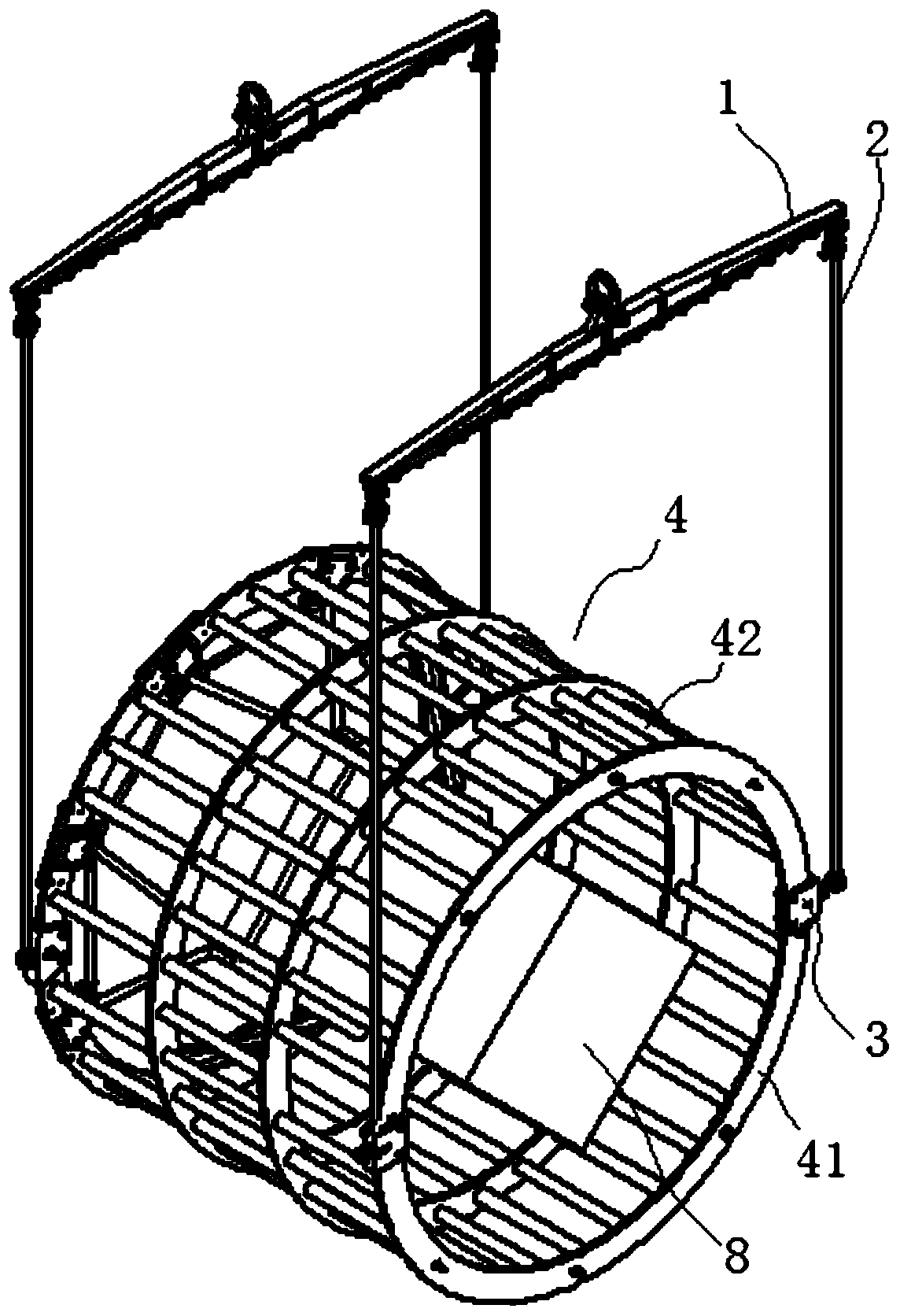

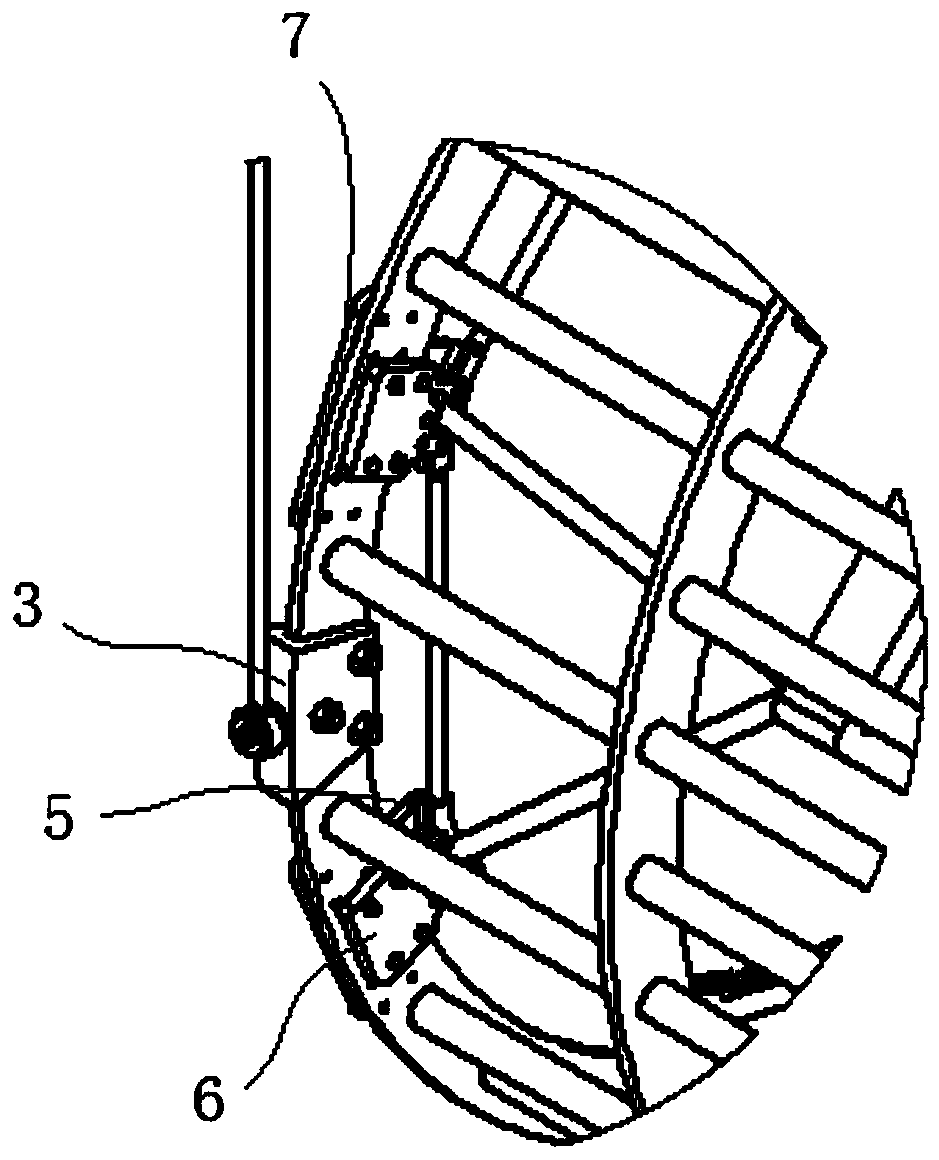

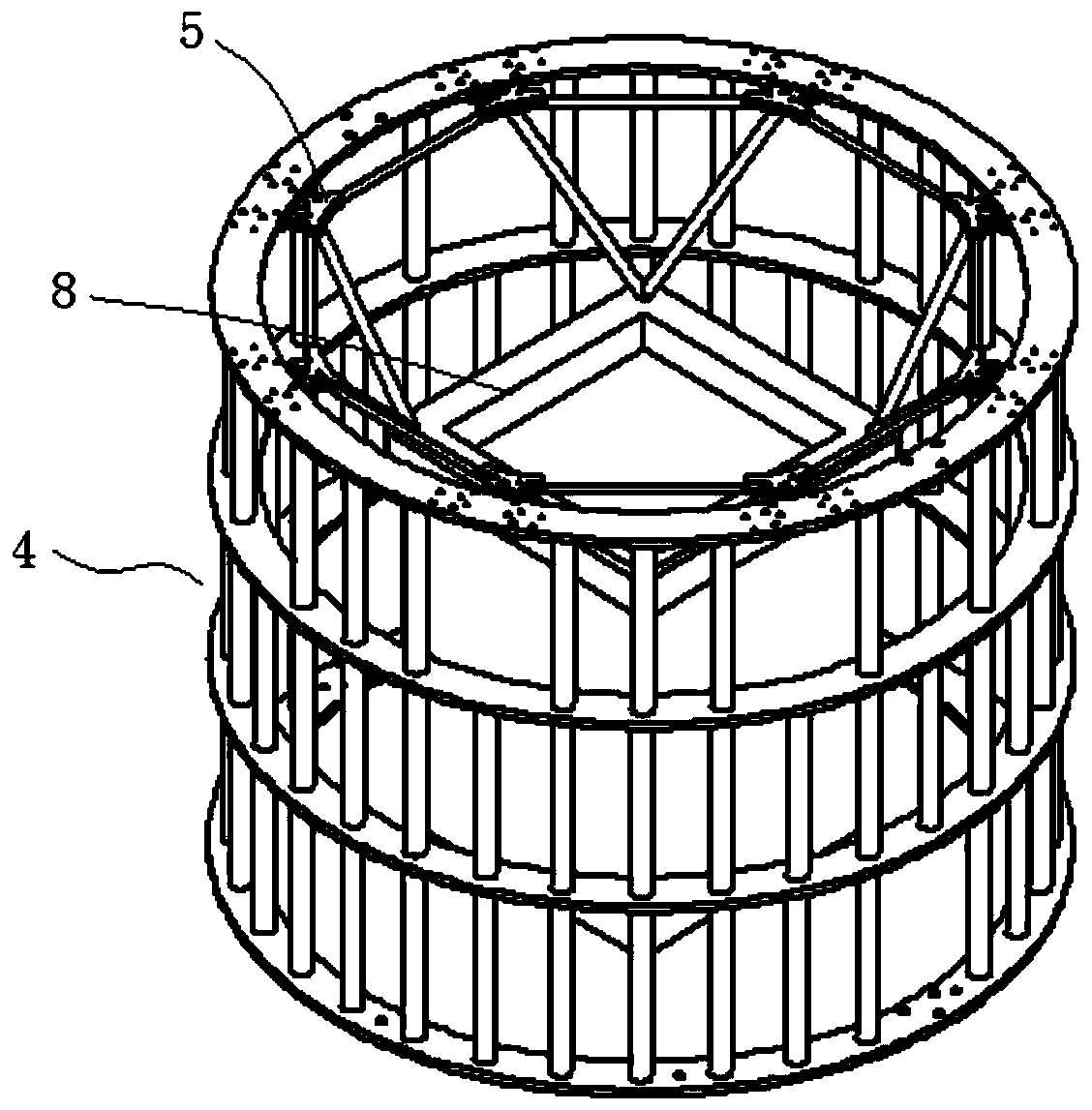

[0021] see Figure 1-4 As shown, a large-scale rocket engine and support overall flip fixture, including:

[0022] The engine connection main frame 4, the main body of the engine connection main frame is a cylindrical structure, including a plurality of annular plates 41 spaced apart from the coaxial center and a plurality of axially evenly spaced connections connecting the annular plates together Rod 42, the two ends of the engine connected to the main frame are respectively connected to two suspension ropes 2 through detachable clamps 3, and every two suspension ropes 2 are detachably connected to a suspension beam 1, and the engine is connected to the main frame. The rack mounting surface of the frame 4 is provided with a plurality of rack mounting surface pads 5, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com