Noncontact angle measuring system and measuring method thereof

An angle measurement, non-contact technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of complex output signal decoding, limited application range, reduced accuracy, etc., to achieve simple system structure, high test accuracy, linearity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

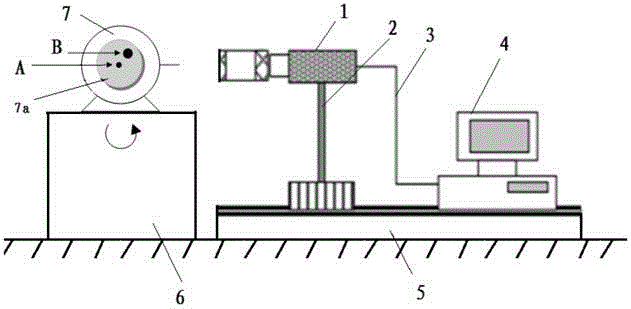

[0031] Such as figure 1 As shown, a kind of non-contact angle measuring system provided by the present invention comprises CCD camera 1, CCD camera tripod 2, USB data cable 3, computer 4, first working platform 5, second working platform 6, CCD camera tripod 2 Placed on the first working platform 5, the CCD camera 1 is fixed on the CCD camera tripod 2; the computer 4 is placed on another position of the first working platform 5, and the computer 4 is connected with the CCD camera 1 through the USB data line 3; the tested The object 7 is a servo control system, the bottom of the measured object 7 is placed on the second working platform 6 , and the lens of the CCD camera 1 is aligned with the rotation axis 7 a of the measured object 7 .

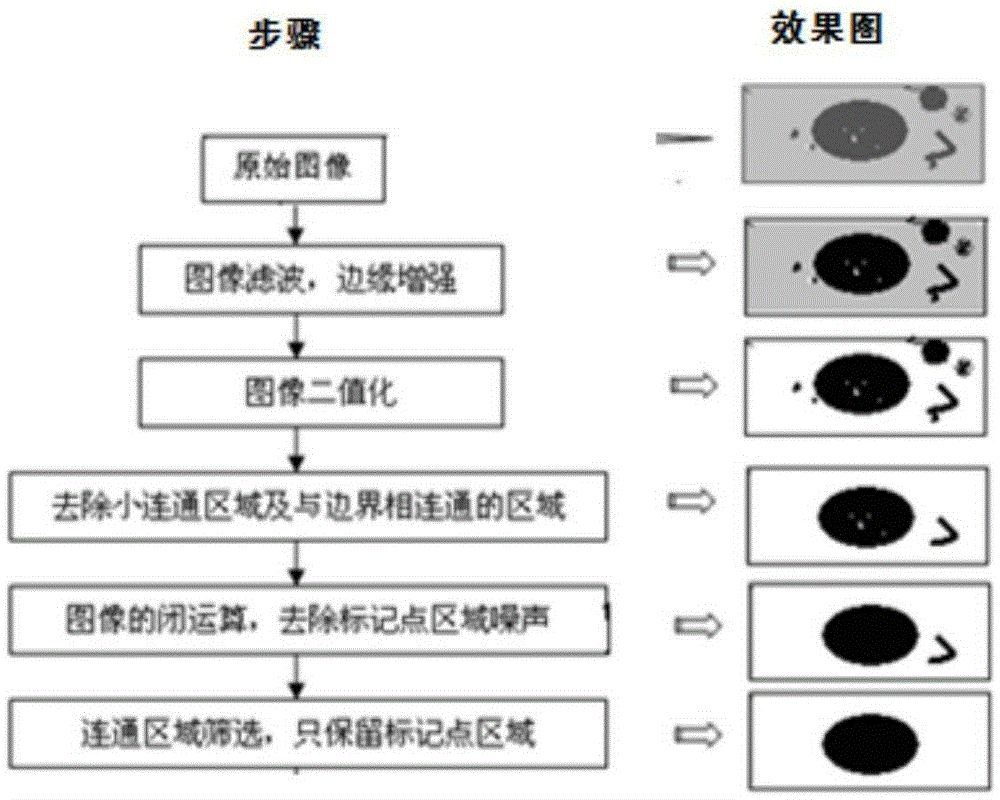

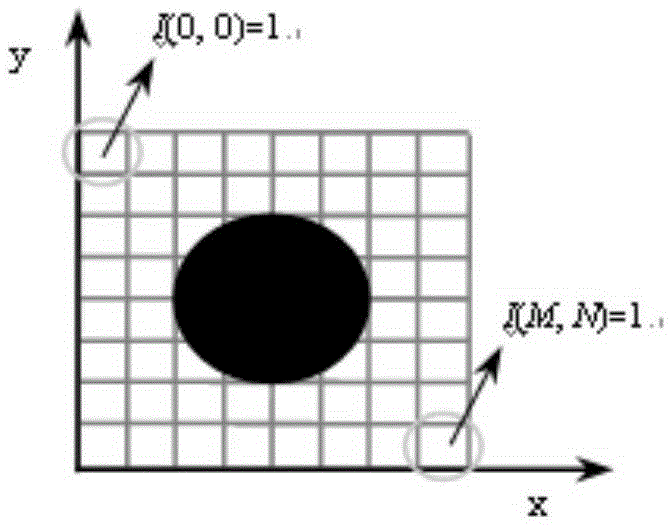

[0032] Such as figure 1 Shown, a kind of non-contact angle measurement method provided by the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com