Tunnel-type chain mesh belt passing drying equipment

A drying equipment and tunnel-type technology, which is applied in the field of tunnel-type chain mesh belt through-type drying equipment, can solve the problems of large physical injury of workers, heavy workload of workers, affecting product quality, etc., and achieve high production efficiency, The effect of reducing labor force and improving labor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

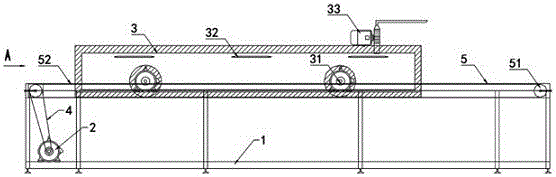

[0010] As shown in Figure 1 and Figure 2, a tunnel type chain mesh belt passing drying equipment is composed of a frame 1, a deceleration motor 2, a furnace body 3, a transmission belt 4 and a conveying device 5. The deceleration motor 2 is located in the The bottom of the rack 1 is connected with the conveying device 5 provided on the top of the rack 1 through the transmission belt 4; the furnace body 3 is installed in the middle of the rack 1, and wraps the conveying device 5 in the middle of the rack 1; the furnace body 3 is Segmented furnace body, multi-stage independent PID temperature control, the temperature in the furnace is uniform; the conveying device 5 is composed of a driven shaft 51 installed at both ends of the frame 1 and a conveyor belt 52 connected to the driven shaft 51; It is characterized in that: both sides of the furnace body 3 are provided with built-in circulating fans 31, the top of the furnace is provided with infrared heating pipes 32, the infrared h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com