Combined type HUD (Head Up Display) back light device

A backlight device and combined technology, which is applied to lighting devices, fixed lighting devices, and components of lighting devices, etc., can solve the complex optical coating process of HUD backlight devices, poor optical coating effect of HUD backlight devices, and low product quality rate. The problem is to overcome the complex optical coating process, improve the quality rate, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

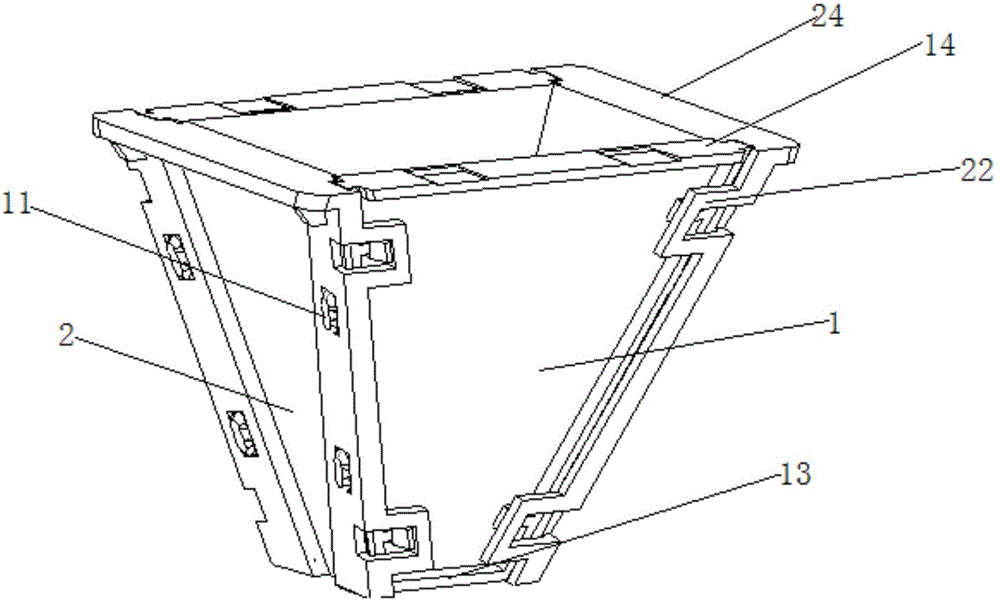

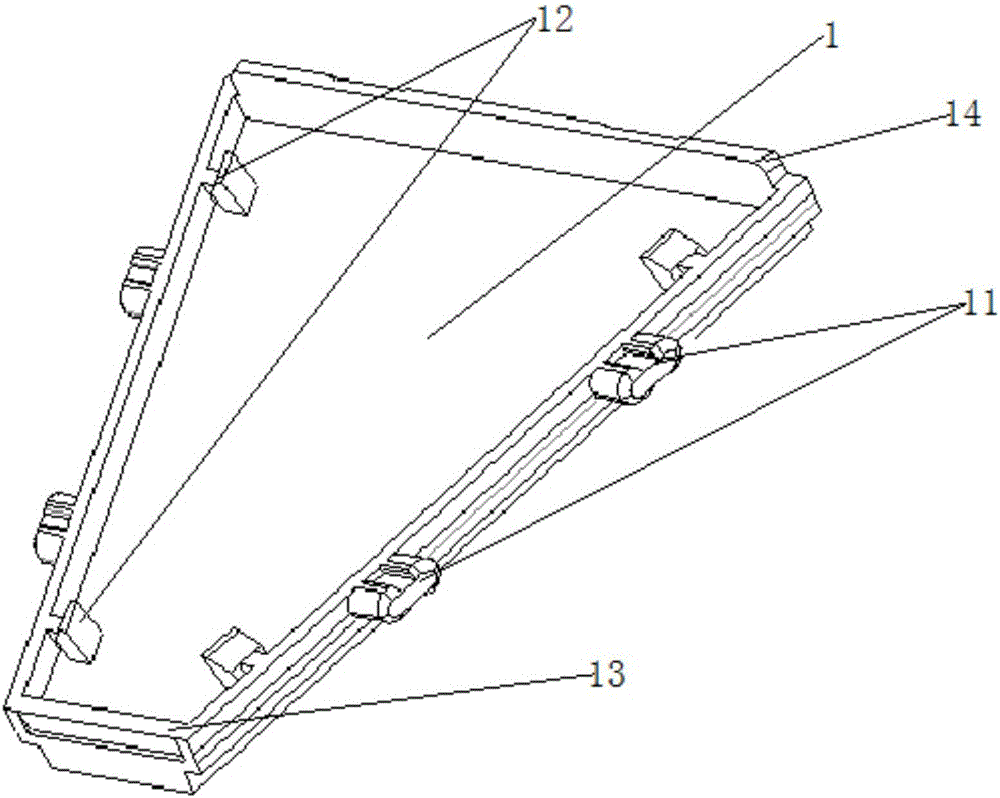

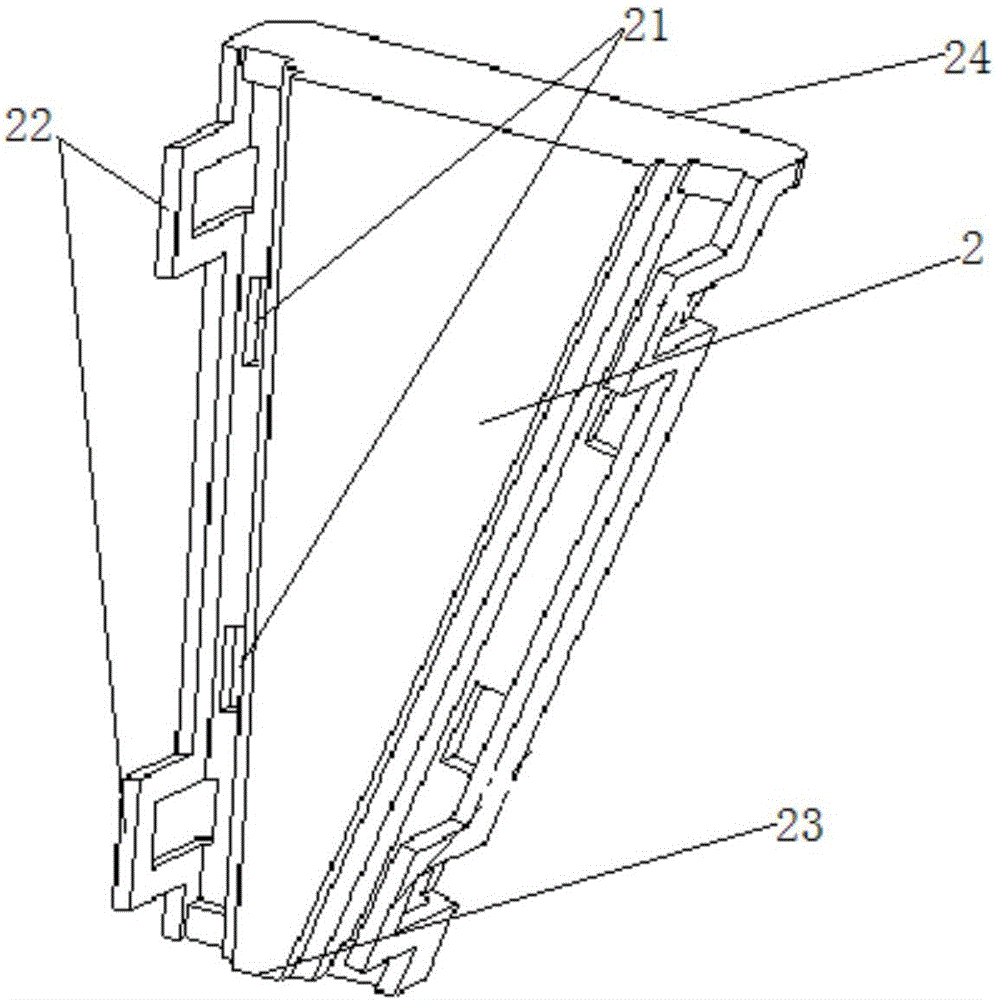

[0012] An embodiment of the present invention provides a combined HUD backlight device, comprising at least two first trapezoidal backlight panels and at least two second trapezoidal backlight panels, at least two first trapezoidal The sides of the second trapezoidal backlight panel are adjacent to form a pyramid structure, and the two sides of the first trapezoidal backlight panel or the second trapezoidal backlight panel are provided with at least four pins and four buckles symmetrically distributed; the second trapezoidal backlight panel Both sides of the second trapezoidal backlight panel or the first trapezoidal backlight panel are provided with pin holes that cooperate with the pins of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com