Servo motor pump

A servo motor and motor pump technology, applied in the field of servo hydraulics, can solve the problems of low volumetric efficiency, the volumetric efficiency of the motor pump cannot be too high, and the motor speed is low, so as to achieve low noise, improve high-speed rotation stability, and eliminate zero gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A servo motor pump provided by the present invention will be described below according to specific embodiments.

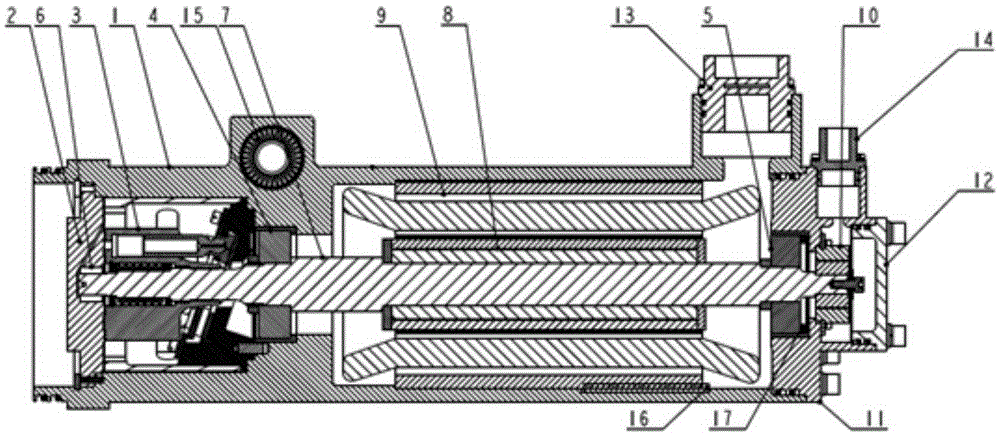

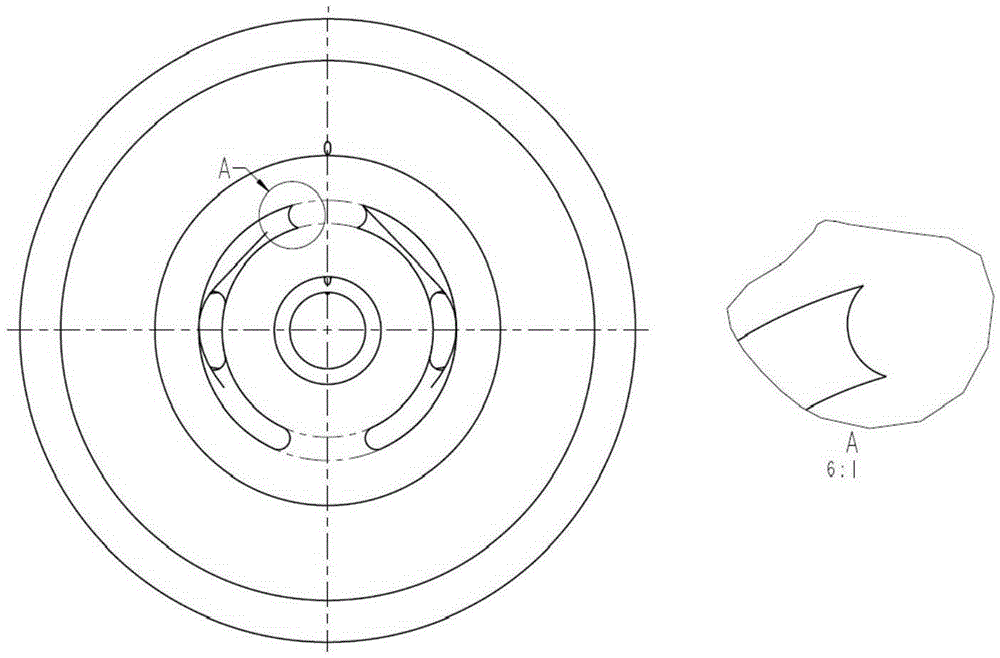

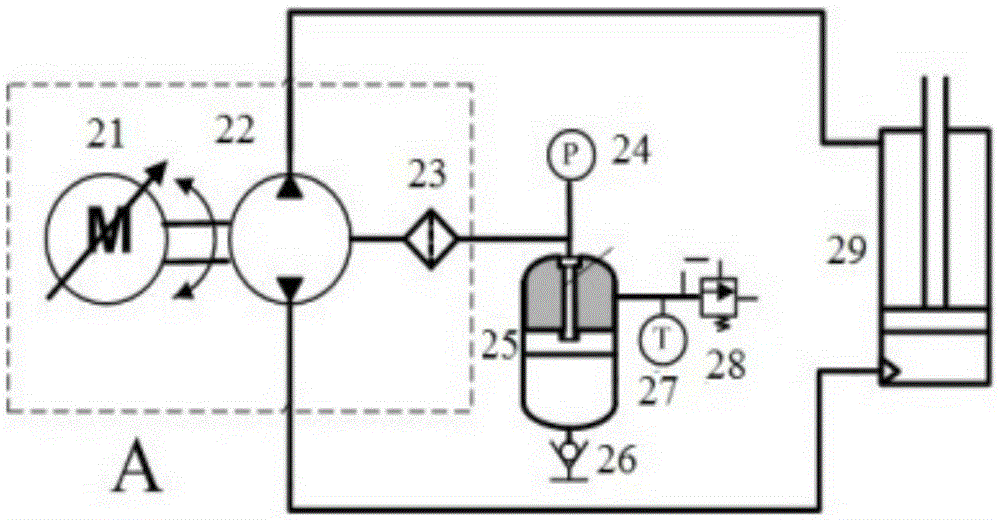

[0019] Such as figure 1 As shown, a servo motor pump provided by the present invention includes a housing 1, an oil separator 2, a plunger pump core 3, an angular contact ball bearing 4, a deep groove ball bearing 5, a needle bearing 6, and a motor pump shaft 7 , motor rotor 8, motor stator 9, resolver 10, mounting base 11, rear end cover 12, power supply electrical connector 13, resolver electrical connector 14, filter element 15, flat key 16, wave spring 17; oil separation The disc 2 is positioned through the seam gap at the left end of the housing 1, and is fixed in the housing 1 by screws. The outer ring of the needle roller bearing 6 is embedded in the oil separator plate 2, and the needle roller bearing 6 is set on the outer ring of the front end of the motor pump shaft 7. Above; the plunger pump core 3 is connected with the motor pump shaft 7 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com