Universal type tunnel heading equipment used for deformed and circular fracture surfaces

A general-purpose technology for tunneling, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems that there is no tunneling equipment and the inability to use circular cross-section tunnel construction, etc., and achieves simple structure, comprehensive performance, and high general-purpose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

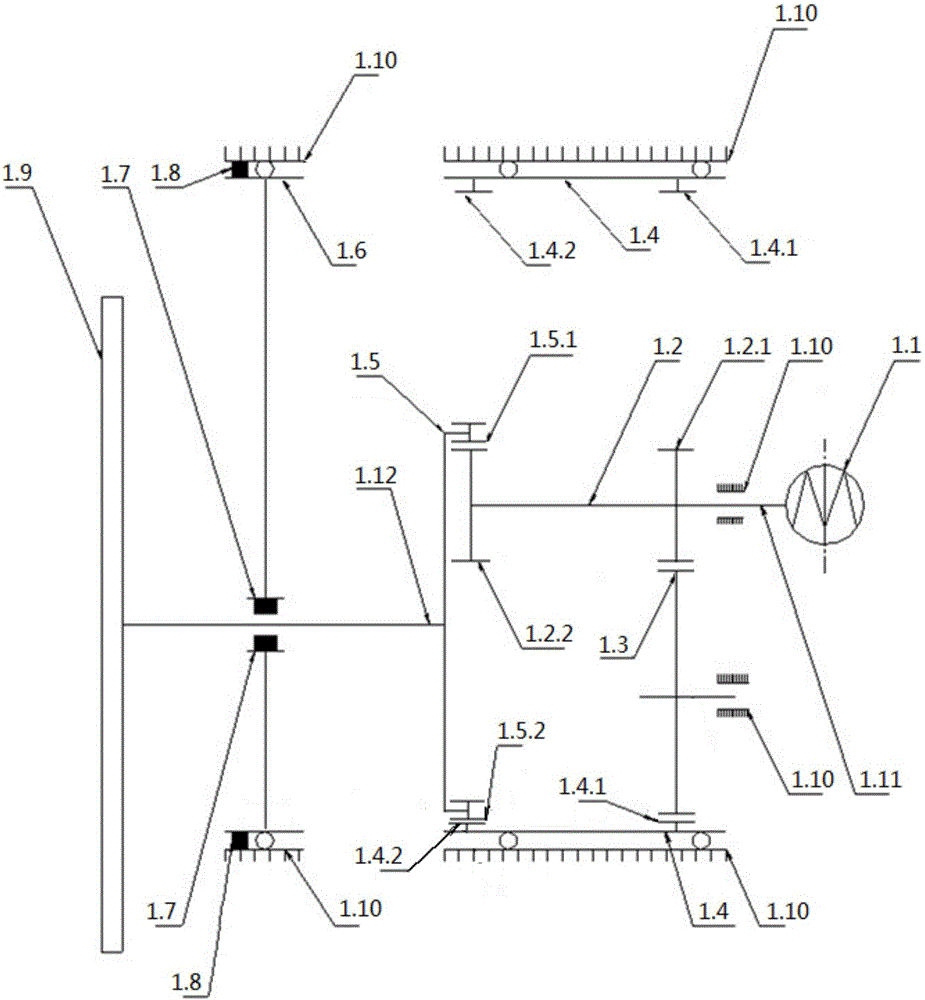

[0016] see figure 1 Schematic diagram of the structure of the present invention, which shows that the general-purpose tunnel boring equipment for special-shaped and circular sections includes a housing 1.10, a motor 1.1, a drive shaft 1.11, a rear large slewing bearing 1.4, a front large slewing bearing 1.6, and a closed differential. Drive train and cutter head 1.9.

[0017] The rear large slewing bearing 1.4 is erected at the rear of the inner cavity of the housing 1.10 through a bearing structure and can rotate therein, and the front large slewing bearing 1.6 is erected inside the housing 1.10 through a bearing structure The front of the cavity and can rotate in it. The front large slewing support 1.6 and the rear large slewing support 1.4 have the same structural size and an inner diameter of 1404 relative lengths. The front large s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com