Excavator bucket with scraper

An excavator and scraper technology, which is applied to mechanically driven excavators/dredgers, mining equipment, tunnels, etc., can solve the problems of narrow space in the side wall guide pit, incomplete excavation by excavators, and large time consumption, etc., to achieve shortening Construction time, easy blade replacement, and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

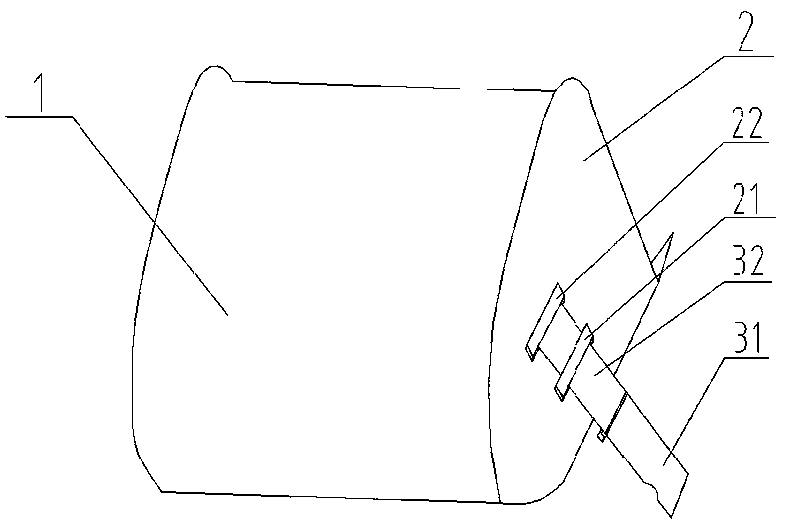

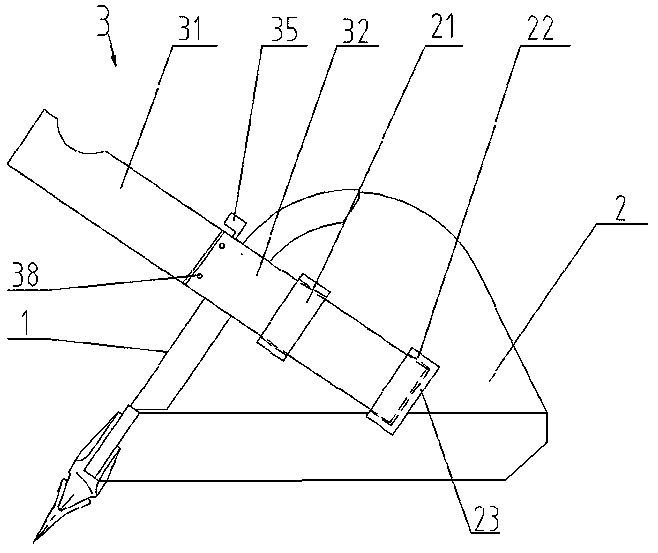

[0027] Embodiment one: if Figure 1 to Figure 2 , Figure 4 to Figure 11 As shown, an excavator bucket with a scraper includes a bucket bottom plate 1, a bucket side plate 2 and a scraper 3; one end of the scraper 3 is detachably connected to the bucket side plate 2 through a connecting device, and the other end is connected to the bucket bottom plate 1 side extends and exceeds the bottom plate 1 of the bucket; the connecting device includes a first fixed flap 21 and a second fixed flap 22 which are fixed on the side plate 2 of the bucket and are parallel to each other. The plate 21 runs through, and a sealing plate 23 is provided at one end of the second fixed folded plate 22; The spacing is 300mm, and they are all made of the same common Q235 steel plate, the inner and outer surfaces are rough to increase the friction with the scraper 3, and the thickness is 20mm; the first fixed folding plate 21 is close to the side of the bucket bottom plate 1, Weld parallel to the botto...

Embodiment 2

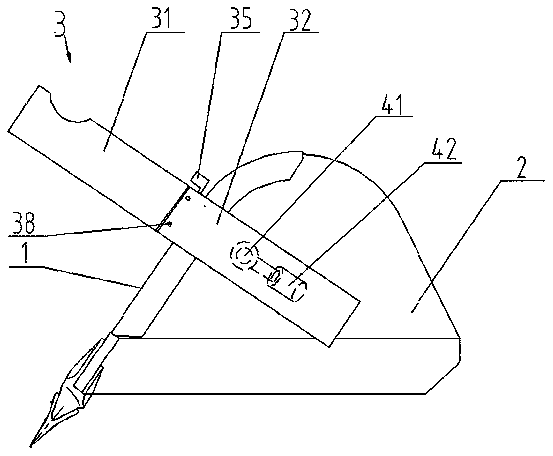

[0030] Embodiment two: if image 3As shown, the difference between the second embodiment and the first embodiment is that another connecting device is used to replace the connecting device of the first embodiment; the connecting device includes a first telescopic sleeve 41 connecting the scraper 3 and the bucket side plate 2 and the second telescopic sleeve 42 that is arranged obliquely and connects the outer wall of the first telescopic sleeve 41 and the bucket side plate 2; the first telescopic sleeve 41 is arranged perpendicular to the bucket side plate 2; the second telescopic sleeve 42 is arranged at the A telescopic sleeve 41 is away from the side of the bucket bottom plate 1; the first telescopic sleeve 41 and the second telescopic sleeve 42 are both provided with springs or filled with elastic materials; When the force is too large, it can be stretched and buffered to prevent the scraper 3 from breaking, and the second telescopic sleeve 42 can support the pressure on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com