A continuous cycle valve

A technology of circulating valve and valve body, which is applied in wellbore/well valve device, wellbore/well components, construction, etc., can solve the problems of reducing drilling time efficiency, economic loss, waste of non-working time, etc., so as to reduce non-operational effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

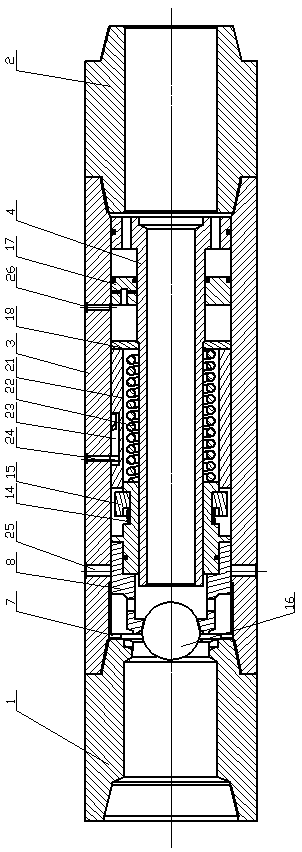

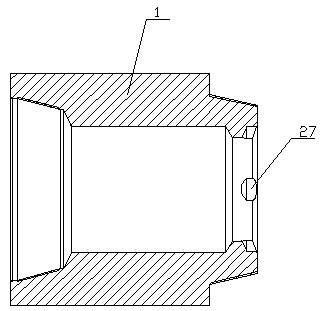

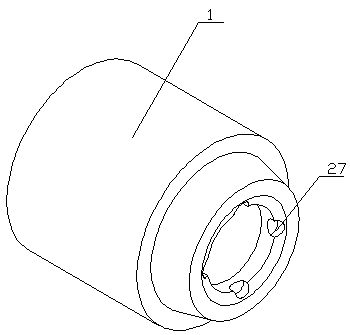

[0030] The continuous cycle valve includes an upper joint 1 , a lower joint 2 , a housing 3 and a valve core shaft 4 . One end of the housing 3 is threaded with an upper joint 1 , and the other end of the housing 3 is threaded with a lower joint 2 ; the housing 3 between the upper joint 1 and the lower joint 2 is provided with a spool shaft 4 . The spool shaft 4 is a variable diameter body, and one end of the spool shaft 4 is provided with a flange 5 , and through holes 6 are evenly distributed on the circumference of the flange 5 . The other end of the valve core shaft 4 is sleeved with a valve piston 8 through a retaining ring A7.

[0031] The valve piston 8 is composed of an upper valve body 9 and a lower valve body 10 , the upper valve body 9 and the lower valve body 10 are fitted together, and a sealing ring is arranged between the upper valve body 9 and the lower valve body 10 . The upper valve body 9 is provided with an arc-shaped switch ball port 11, and valve piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com