Curved limited movement type anti-wear sucker rod and manufacturing method thereof

A sucker rod and cambered surface technology, which is applied in the direction of drill pipe, earth square drilling, cleaning equipment, etc., can solve the problems of centralizer looseness, inability to prevent partial wear, and failure of anti-partial wear, and achieve change in line contact mode, avoid breakage, effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

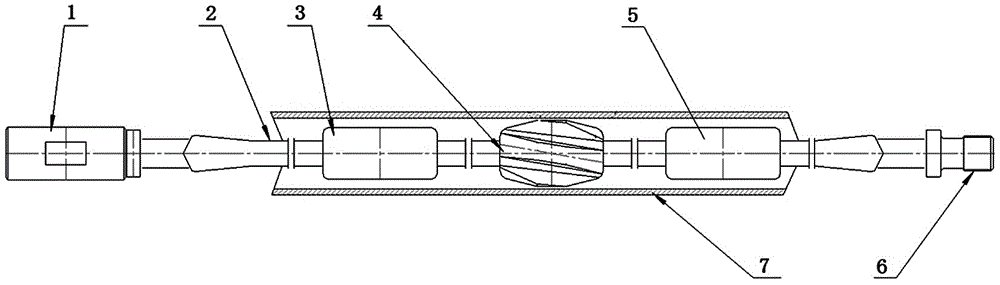

[0029] Such as image 3 , 4 As shown in . And between the second stopper 5, the upper centralizer 4 is cast, and the centralizer 4 can be slidable or fixed, forming the center of the sucker rod body 2, casting the first and second stoppers 3, 5 and the centering body 4 are integrated arc surface limit movement anti-wear sucker rod.

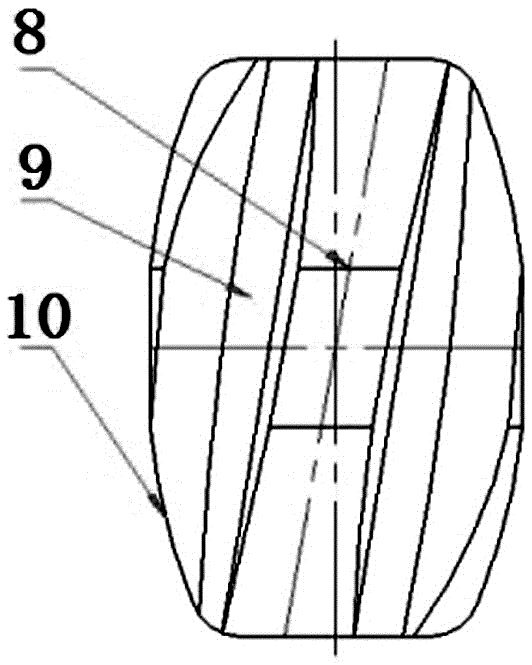

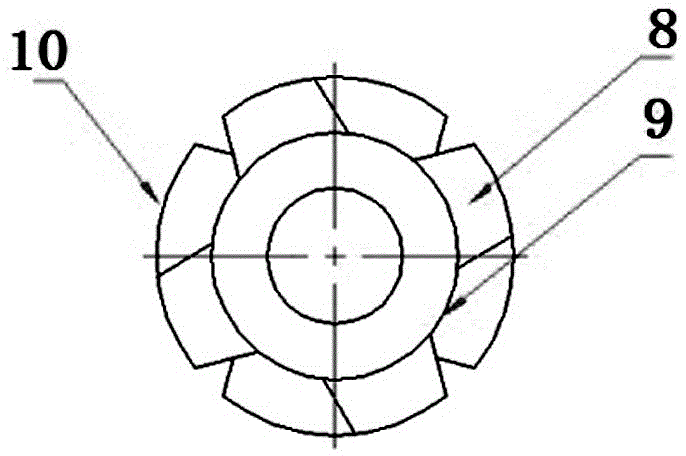

[0030] Such as figure 1 , 2 As shown, there are four spiral bosses 8 on the arc surface of the outer circumference side of the centralizer 4, and there are spiral grooves 9 between two adjacent spiral bosses 8 as oil flow channels, and the outer circle of the centralizer 4 is made of Curved surface 10 (olive).

[0031] Several bosses on the peripheral side of the centralizer are in the shape of straight ribs, and the grooves between the two bosses are linear grooves, serving as oil flow channels. The outer circle of the centralizer is cylindrical.

[0032] In the prior art, the columnar centralizer is in the curved well section of the oil we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com