Fuel tank cap lock for car

A fuel tank and cover lock technology, which is applied in the field of auto parts, can solve the problems of easy forgetting to lock the fuel tank cover lock and inconvenient operation, and achieve the effects of reducing the possibility of safety accidents, reducing safety hazards, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

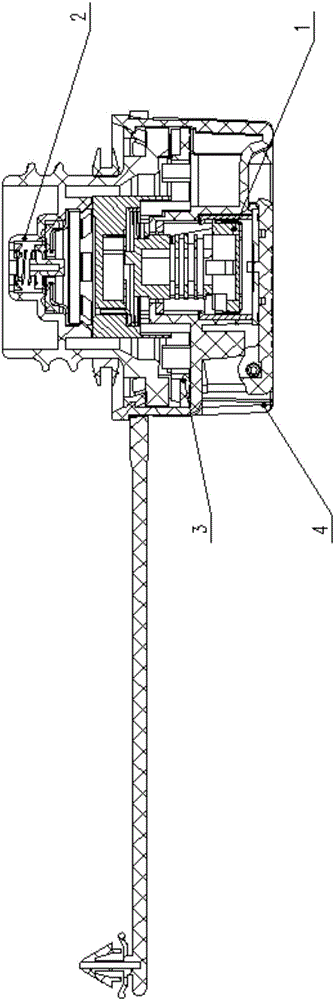

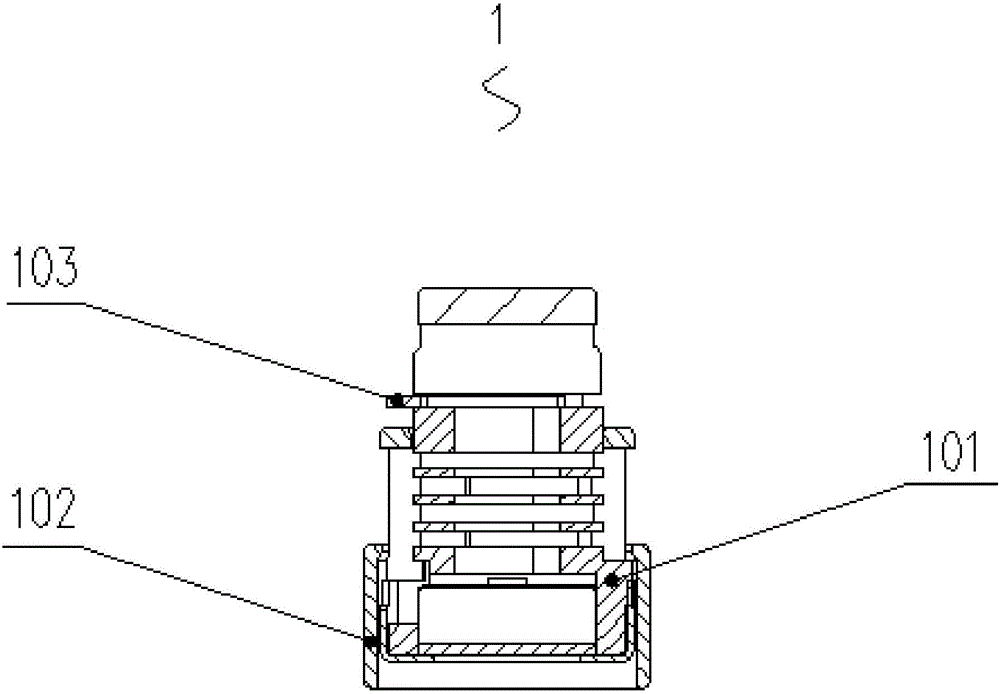

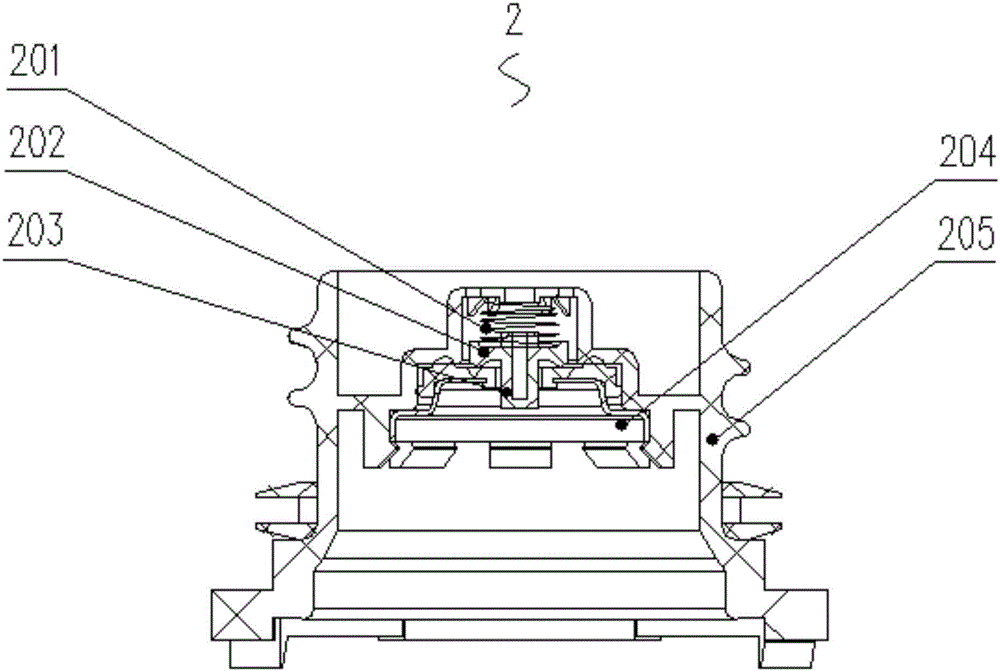

[0029] A fuel tank cap lock for vehicles, such as Figure 1-11 As shown, a lock core assembly 1 is included, which is characterized in that a lock assembly 3 is provided on the lock core assembly 1, and the lock assembly 3 includes a lock ratchet 301, a lock pawl 302, a lock sleeve 304 and a reset torsion spring 303, The locking ratchet wheel 301 is provided with eight bosses 3011, the locking pawl 302 is attached to the boss 3011, the locking pawl 302 is arranged in the lock sleeve 304, and the lock sleeve 304 is provided with a clamping block 3041 and a lock sleeve 304 There is also a reset torsion spring 303; when the locking block 3041 is engaged with the locking pawl 302, the lock cylinder assembly 1 is unlocked, and the locking ratchet 301 rotates to push the locking pawl 302 to reset the torsion spring 303 to drive the locking block 3041 out of lock The pawl 302 and the block 3041 drive the lock cylinder assembly 1 to rotate through the lock sleeve 304. The locking pawl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com