Arc-shaped double-clamp system required by high-frequency vibration of steel pipe pile

A technology of high-frequency vibration and steel pipe piles, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., and can solve problems such as difficult construction, unsatisfactory results, and large pile opening deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

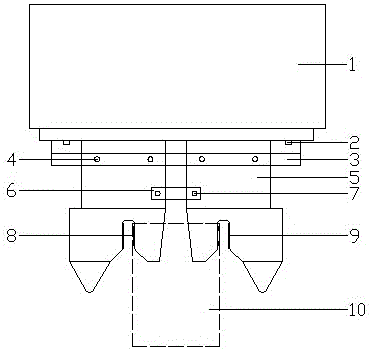

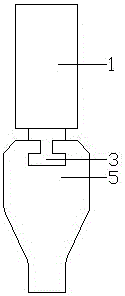

[0012] The implementation manner of the patent of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0013] Such as figure 1 , as shown in 2, the arc-shaped vibration double clamp system required for high-frequency vibration construction of steel pipe piles of the present invention includes a vibratory hammer 1, bolt A2, beam 3, bolt B4, two arc-shaped clamps 5, steel connection Plate 6, arc clip 8, bolt C7, retractable clip 9.

[0014] The beam 3 is fixedly connected to the vibrating hammer 1 through the bolt A2, and the two arc-shaped clamps 5 are embedded in the slot of the beam, and can move bidirectionally in the slot of the beam to realize the adjustment of the distance, which is used to meet the different diameters of steel pipe piles 10 According to the clamping requirements, the two arc-shaped fixtures 5 after adjusting the spacing are fixedly connected to the beam 3 through the bolt B4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com