Bridge jacking system based on releasable prestressed underpinning system and construction method thereof

A prestressed and disassembled technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of bridge structures that cannot be applied to self-heavy, small bearing capacity, heavy workload, etc., to ensure bearing capacity and facilitate connection and installation , The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described and illustrated through specific examples below.

[0042] Unless otherwise specified, the raw materials used in the examples of the present invention are commonly used raw materials in the field, and the methods used in the examples are conventional devices and conventional methods in the field.

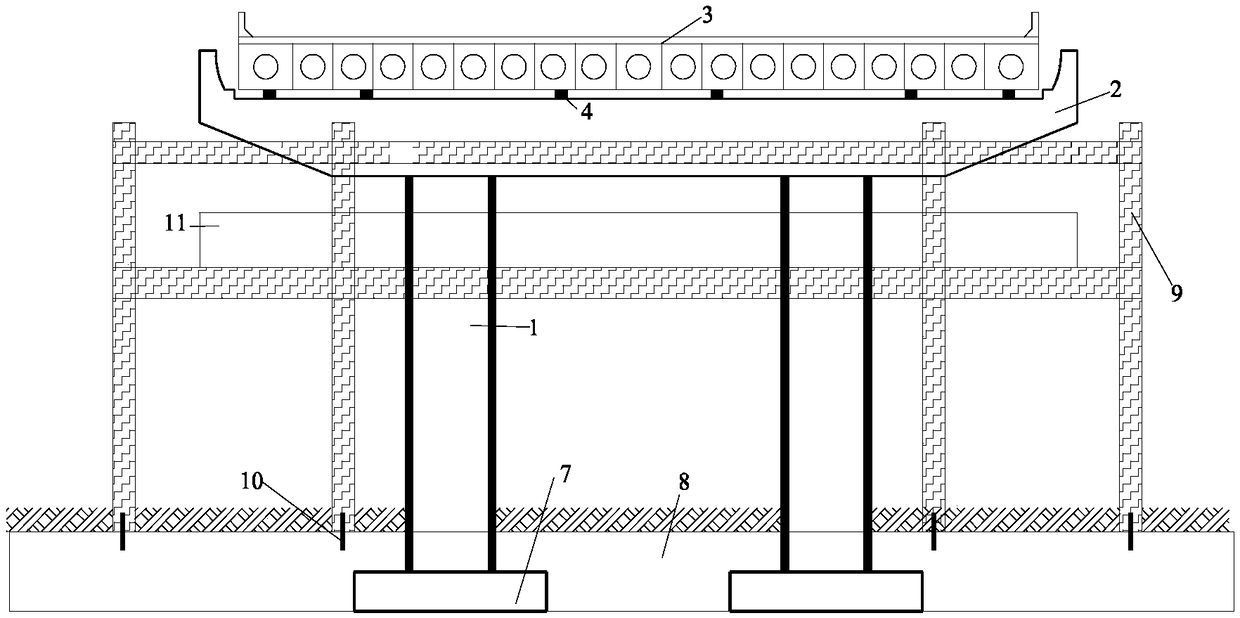

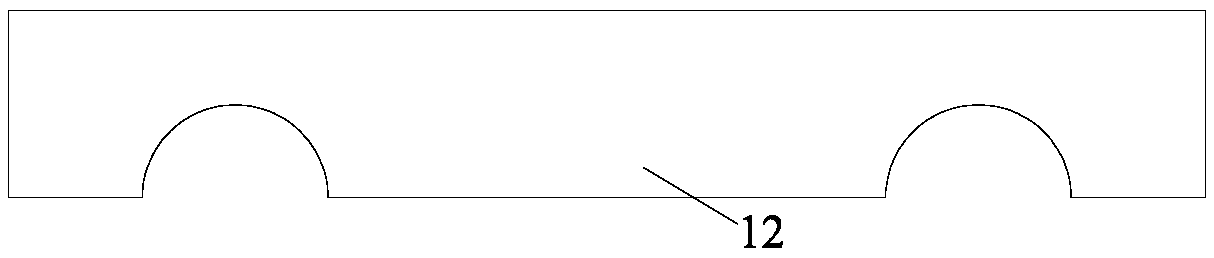

[0043] A bridge jacking system based on a detachable prestressed underpinning system, such as Figure 1-Figure 11As shown, it includes the enlarged cap 8 obtained by enlarging the original cap 7 of the bridge. The enlarged cap 8 is pre-installed with embedded anchor bolts 10, and the enlarged cap 8 is supported by pre-embedded anchor bolts 10. Use a plug-in construction frame 9; install an adjustable hoop prestressed support platform 11 on the plug-in construction frame 9 for support as a bridge jacking reaction platform; the bridge includes a cover beam 2 and a bridge to be lifted on the cover beam 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com