Method for selecting axis of large cavern under high ground stress condition

A technology of high in-situ stress and in-situ stress, applied in the directions of hydroelectric power generation, hydroelectric power station, geophysical measurement, etc., can solve the problems of large dip angle of the maximum principal stress, reduced influence of the maximum principal stress, and no good solution, etc. The effect of support measures and design risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

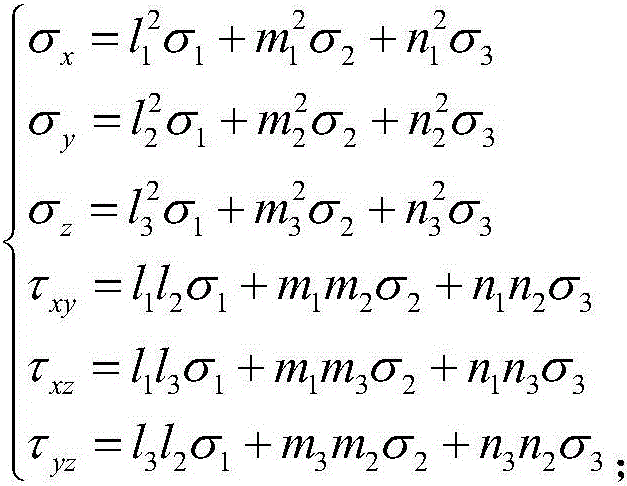

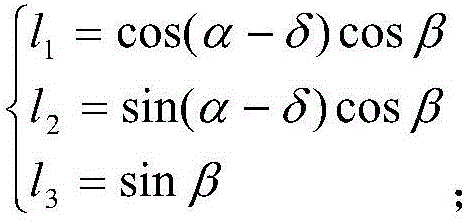

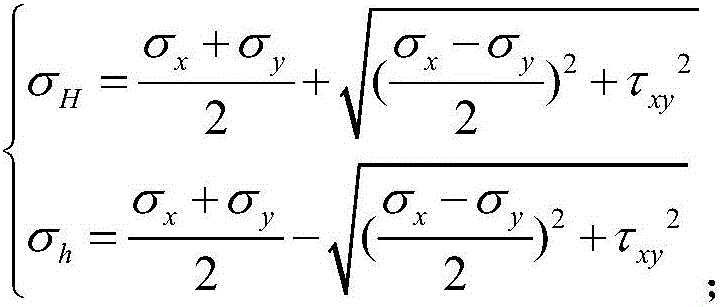

Method used

Image

Examples

Embodiment

[0046] In order to verify that under the condition of high ground stress, the self-stabilization ability of the surrounding rock mass obtained by using the maximum horizontal stress direction as the reference standard of the cavern axis is stronger than that obtained by using the maximum principal stress horizontal projection direction as the reference standard, two test schemes are specially designed. Compared.

[0047] The two schemes use the same in-situ stress field (see Table 1), the same geological conditions, both use the Mohr-Coulomb constitutive model with tensile stress truncation, the same physical and mechanical parameters of the rock mass (see Table 2), the same cavern size, and the boundary Same conditions. Scheme 1 uses the maximum principal stress σ 1 The horizontal projection direction is the direction of the cavern axis (NW40.7°), and the maximum horizontal stress σ H The direction is the direction of the cavern axis (NW24.1°). The calculation process uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com