Method for reducing nucleus density in procedures for synthesizing single-crystal graphene by aid of chemical vapor deposition processes

A technology of chemical vapor deposition and single crystal graphene, which is applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as poor operability, lack of in-depth essential mechanism, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

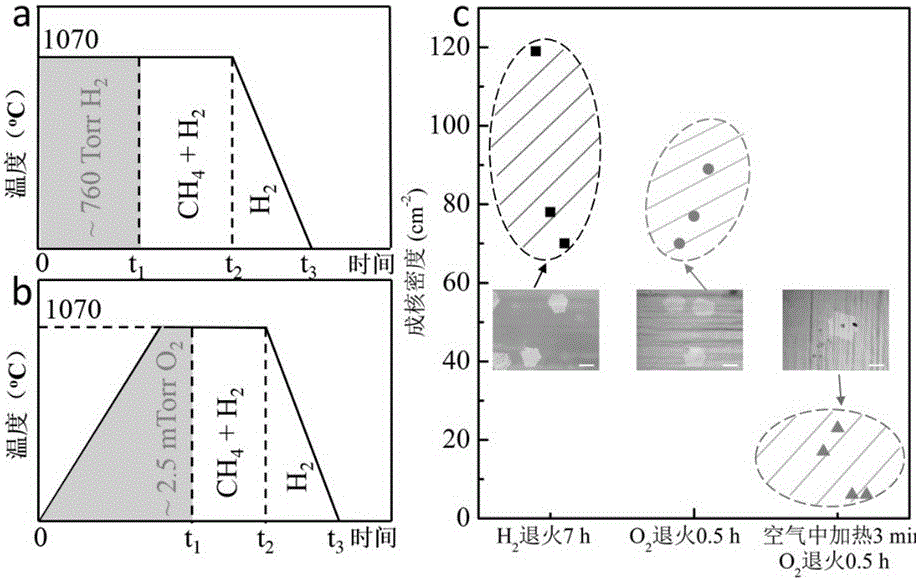

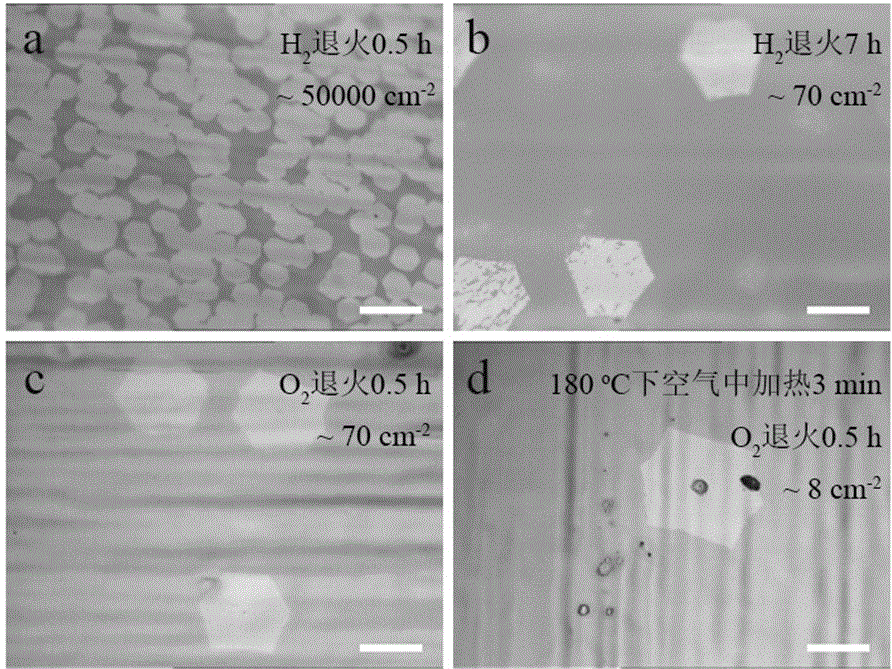

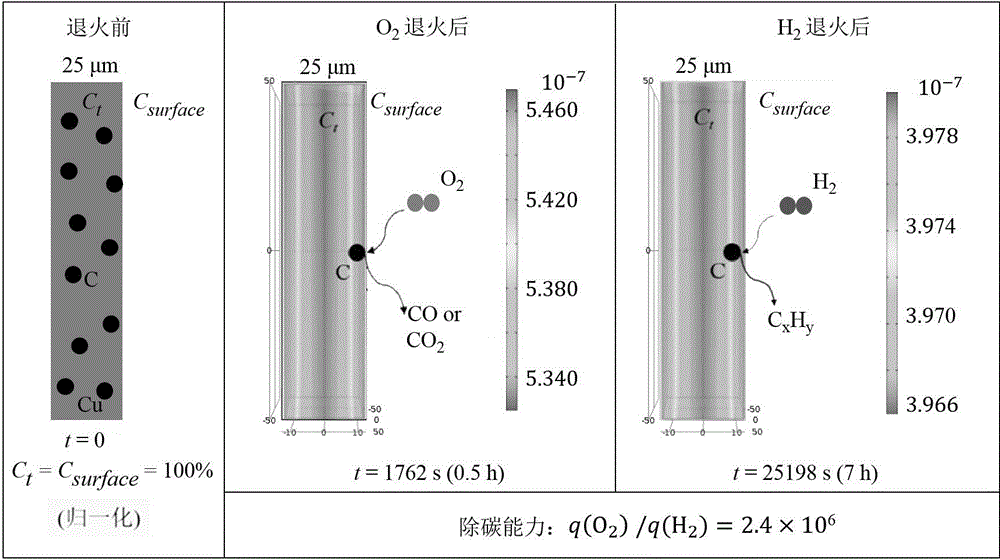

[0030] In the process of synthesizing single crystal graphene by chemical vapor deposition method, the following methods are used to reduce the crystal nucleus density:

[0031] (1) Pretreatment of metal copper substrate: put a rectangular copper sheet with a thickness of 25 μm in a phosphoric acid solution (H 3 PO 4 :H 2 O = 3:1) for electrochemical polishing, then washed 5 times with deionized water, and blown dry with a nitrogen gun; then use a clean glass rod, with the help of tweezers, roll the copper sheet along the width direction into openings at both ends A barrel shape, and the growth result of the inner surface of the barrel-shaped copper substrate is used as the research object;

[0032] (2) Annealing of metal copper substrate: In chemical vapor deposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com