Ionic rare-earth ore infiltration system reinforced leaching method

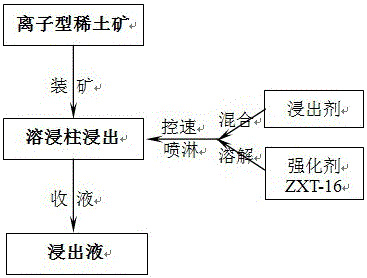

An ionic rare earth ore, enhanced leaching technology, applied in the direction of improving process efficiency, can solve problems such as high production cost, poor seepage effect, insufficient reaction, etc., and achieve the effect of improving ore body expansion and inhibiting expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 200g of potassium alkylsulfonate succinamate, 100g of sodium methylaminoethylsulfonate, 120g of sodium stearylsulfamate, and 50g of potassium phosphate, and stir with a beaker as a container and a magnetic stirrer for 30~ 40min to get the enhancer ZXT-16.

Embodiment 2

[0036] Mix 180g of potassium alkylsulfonate succinamate, 100g of sodium methylaminoethylsulfonate, 140g of sodium stearylsulfamate, and 50g of potassium phosphate, and stir with a beaker as a container and a magnetic stirrer at normal temperature and pressure for 30~ 40min to get the enhancer ZXT-16.

Embodiment 3

[0038] Mix 230g of potassium alkylsulfonate succinamate, 100g of sodium methylaminoethylsulfonate, 130g of sodium stearylsulfamate, and 50g of potassium phosphate, and stir with a beaker as a container and a magnetic stirrer for 30~ 40min to get the enhancer ZXT-16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com