Method for producing phycoerythrin and polyunsaturated fatty acid by using R. salina

A technology of unsaturated fatty acids and Haematospora salina, applied in the direction of microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of low relative content of SA, high purification cost, bad smell, etc. Achieve the effect of reducing the cost of pre-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Halobacter salina (R.salina) seed medium:

[0033] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

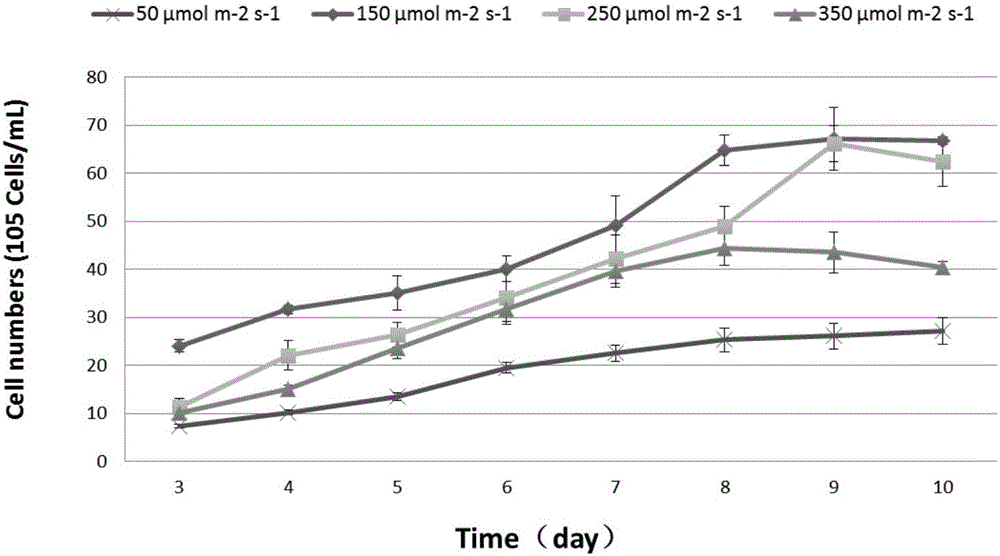

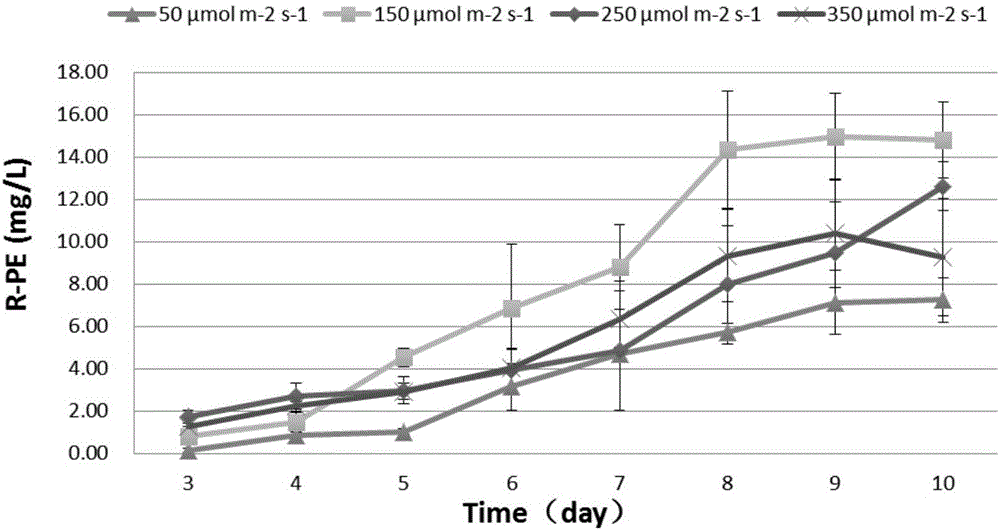

[0034] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours. The second-generation seeds are inserted into a 400mL / 600mL explosion-type reactor with a 20% (V / V) inoculation amount. The reactor is an artificial seawater fermentation medium, and the white light intensity is 50-350 μmol m -2 the s -1 , the fermentation condition is 23℃, the aeration rate is 0.1m 3 min, fermented for 10 days.

[0035] The composition of the artificial seawater fermentation medium is, NaCl ...

Embodiment 2

[0046] Halobacter salina (R.salina) seed medium:

[0047] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

[0048] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours. The second-generation seeds are inserted into a 400mL / 600mL explosion reactor with a 20% (V / V) inoculation amount. The reactor is an artificial seawater fermentation medium, and the red light intensity is 50-350 μmol m -2 the s -1 , the fermentation condition is 23℃, the aeration rate is 0.1m 3 min -1 , fermented for 10 days. Among them, the wavelength of the red light is 590-670 nm, and the wave peak is 640...

Embodiment 3

[0060] Halobacter salina (R.salina) seed medium:

[0061] Salina derived seawater, glycerin 10%, Na 2 EDTA·2H 2 O 80mM, H 3 BO 3 2mM, FeCl 3 ·6H 2 O5.02mM, MnSO 4 ·H 2 O 0.01mM, ZnSO 4 ·7H 2 O 0.001mM, CoCl 2 ·6H 2 O 0.001mM, Na 2 EDTA·2H 2 O50mM, HCl 0.1M, HEPES buffer pH 7.8 10mM, Vitamin B 12 0.3g / L.

[0062] The seeds were cultured for two generations, and each generation was carried out in a Erlenmeyer flask with a liquid volume of 50 mL / 250 mL, with an inoculum size of 20% (V / V), and cultured on a shaking table at 23° C. and 120 rpm for 48 hours. The second-generation seeds are inserted into a 400mL / 600mL explosion-type reactor with a 20% (V / V) inoculation amount. The reactor is an artificial seawater fermentation medium, and the blue light intensity is 50-350 μmol m -2 the s -1 , the fermentation condition is 23℃, the aeration rate is 0.1m 3 min -1 , fermented for 10 days. Among them, the wavelength of the blue light is 420-510 nm, and the wave peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com