High-detergency low-foam semi-synthesis grinding fluid and preparation method thereof

A clean, semi-synthetic technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as toxicity of reproductive system, and achieve the effects of short foam duration, reduced dosage, and reduced foam generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

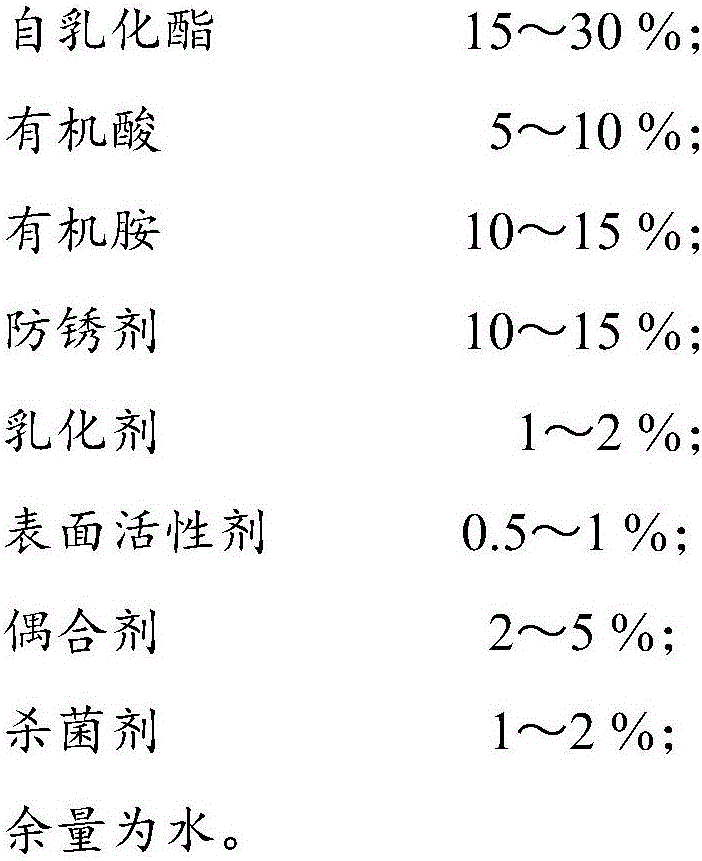

[0047] A kind of semi-synthetic grinding fluid with high cleanliness and low foaming, comprises the component of following weight percentage content:

[0048]

[0049]

Embodiment 2

[0051] A kind of semi-synthetic grinding fluid with high cleanliness and low foaming, comprises the component of following weight percentage content:

[0052]

Embodiment 3

[0054] A kind of semi-synthetic grinding fluid with high cleanliness and low foaming, comprises the component of following weight percentage content:

[0055]

[0056]

[0057] The high-cleaning and low-foaming semi-synthetic grinding fluid in embodiments 1 to 3 can be prepared according to the following production steps:

[0058] Step A, add self-emulsifying ester, organic acid, organic amine, antirust agent and emulsifier to the reaction kettle in sequence according to the formula, control the temperature at 25-40°C, and stir for 30 minutes;

[0059] Step B, add water, bactericide, and coupling agent to the reaction kettle in turn, and continue to stir for 30 minutes;

[0060] Step C, finally adding the surfactant into the reaction kettle and stirring for 30 minutes;

[0061] Step D, sampling and analyzing and packing.

[0062] The stirring speed of the stirring tank is controlled at 400-800rpm.

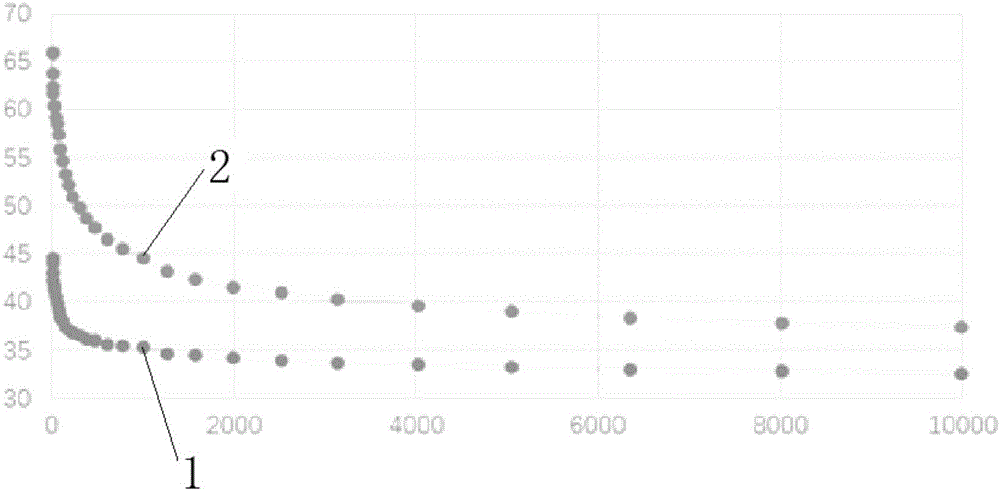

[0063] In the development process of the high-cleaning and low-foamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com