Moisture-resistant randomly-fixed adhering film

A moisture-resistant and sticking technology, applied in the direction of pressure-sensitive films/sheets, film/sheet-shaped adhesives, adhesive additives, etc., can solve environmental protection requirements, insufficient overall setting strength, aging and deformation of double-sided tapes, etc. problems, to achieve the effect of preventing the calligraphy and painting from growing mildew and suffering from insects, shortening the mounting time and manpower, and preventing aging and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

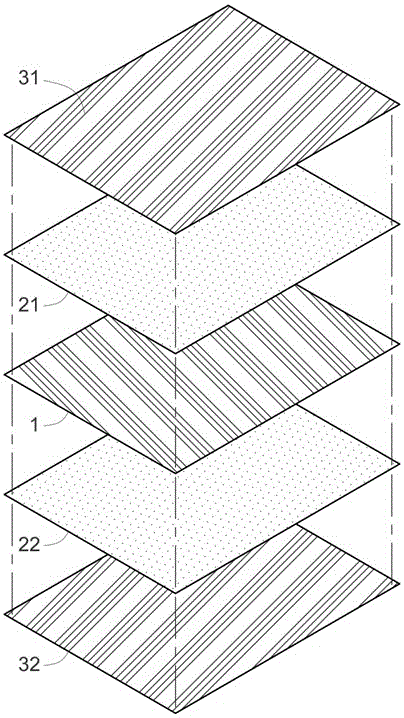

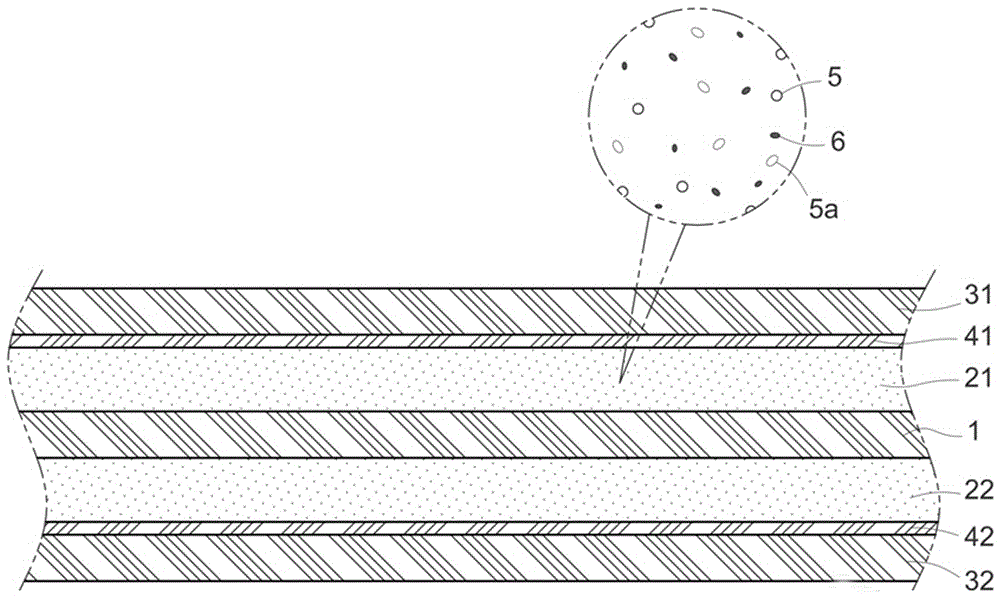

[0031] see figure 1 , a moisture-resistant random fixed adhesive film, including a sheet-type substrate layer 1, the first adhesive layer 21 and the second adhesive layer 22 capable of pasting foreign objects are respectively arranged on both sides, and the first adhesive layer The first release layer 31 is covered on the surface of the layer 21, and the second release layer 32 is covered on the surface of the second adhesive layer 22, wherein:

[0032] The substrate layer 1 can be made of plastic material, so that the substrate layer 1 can elastically set the first adhesive layer 21 and the second adhesive layer 22, and the first adhesive layer 21 and the second adhesive layer 22 raw materials include by weight percentage: SEBS 45% ~ 55%, naphthenic oil 25% ~ 35% and white wax oil 15% ~ 25%, so that the first adhesive layer 21 and the second adhesive layer 22 Able to withstand moisture, accept washing and repeated pasting of foreign objects.

[0033] The SEBS is a linear th...

Embodiment 1

[0052] A moisture-resistant free fixed adhesive film, comprising a sheet-type base material layer, the first adhesive layer and the second adhesive layer are respectively laid on both sides of the base material layer, and the first adhesive layer and the second adhesive layer The surface of the adhesive layer is covered with a first release layer and a second release layer respectively; the raw materials of the first adhesive layer and the second adhesive layer are by weight percentage: SEBS 45%, naphthenic oil 35% and White wax oil 20%; The base layer is made of PET material; Between the first adhesive layer and the first release layer, between the second adhesive layer and the second release layer, a release layer is coated. Forming agent; the release agent is magnesium silicide; the first release layer and the second release layer are made of PP material; the outer surface of the first release layer or the second release layer is printed with text , graphics or photo images...

Embodiment 2

[0054] A moisture-resistant free fixed adhesive film, comprising a sheet-type base material layer, the first adhesive layer and the second adhesive layer are respectively laid on both sides of the base material layer, and the first adhesive layer and the second adhesive layer The surface of the adhesive layer is respectively covered with a first release layer and a second release layer; the raw materials of the first adhesive layer and the second adhesive layer are calculated by weight percentage: SEBS 50%, naphthenic oil 25%, White wax oil 15%, aromatic microcapsules 5%, color-changing microcapsules 4.99% and nano silver 0.01%; the base material layer is made of PET material; between the first adhesive layer and the first release layer, A release agent is coated between the second adhesive layer and the second release layer; the release agent is manganese silicide; the first release layer and the second release layer are made of PE materials; Text, graphics or photo images ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com