Air conditioner wind wheel material and its preparation method and application

A technology for air-conditioning and air-conditioning, which is applied in the fields of air-conditioning wind rotors and air conditioners, air-conditioning wind-wheel materials and their preparation, air-conditioning wind-wheel materials, and preparation of air-conditioning wind-wheel materials, which can solve peculiar smells, affect air quality, dust and microbial shedding, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

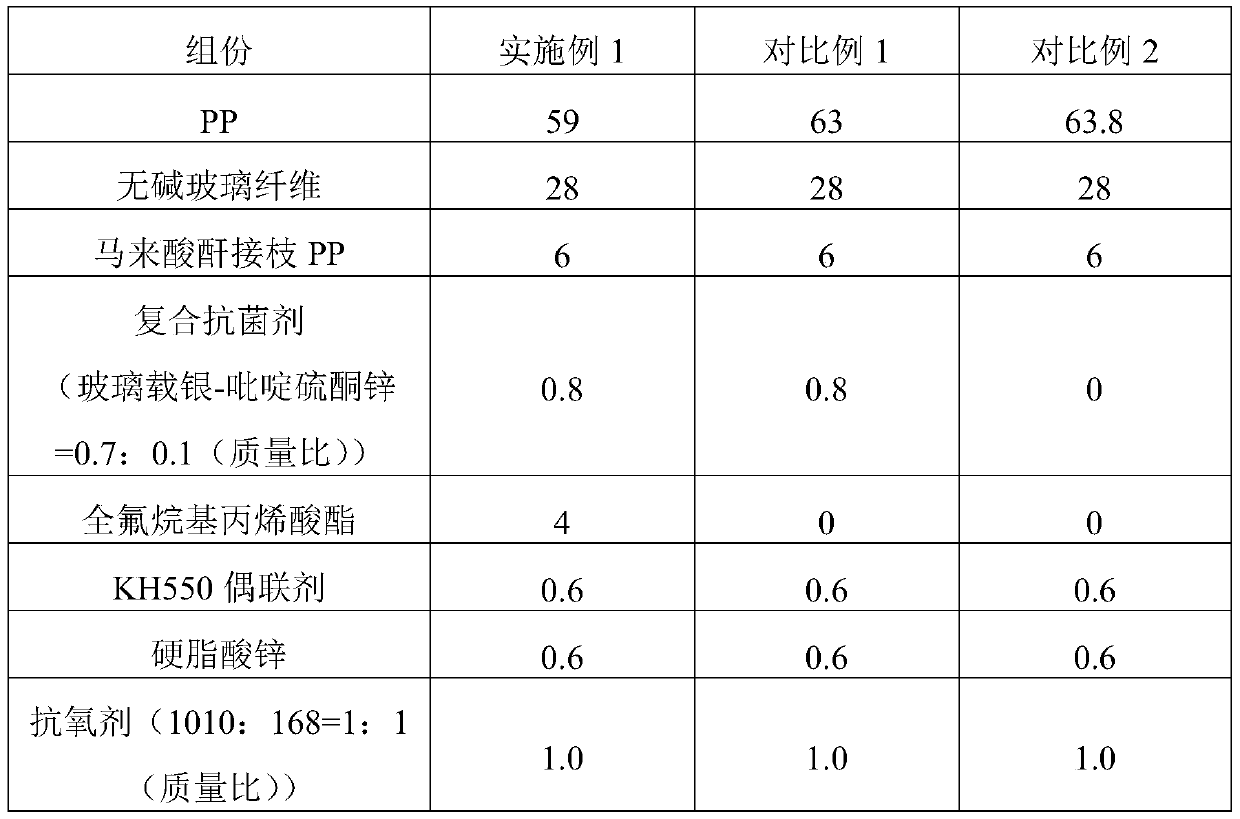

[0068] In this embodiment, the centrifugal wind wheel material of the air conditioner is prepared, and the specific formula is shown in Table 1.

[0069] Table 1. Raw materials and proportions of centrifugal wind wheel materials (mass fraction unit: %)

[0070]

[0071] The raw materials (except glass fiber) according to the above ratio are mixed and stirred evenly and then added to the hopper of the extruder, while the pretreated glass fiber is introduced from the opening of the barrel of the extruder separately, and all components are heated, Shearing, mixing, plasticizing into a uniform melt, cooling and pelletizing after passing through the die, to obtain the required air-conditioning centrifugal fan material. Wherein, the temperature range of each section of the extruder is 190-230° C., and the screw speed is 120-140 r / min.

Embodiment 2

[0077] In this example, with reference to GBT 17037.1-1997, the centrifugal wind wheel materials prepared in Example 1, Comparative Example 1 and Comparative Example 2 were injection molded, and the obtained samples were subjected to mechanical performance tests, antibacterial and antifungal tests, surface Performance testing and accelerated testing against dust accumulation.

[0078] Specifically, the mechanical performance test includes tensile, bending and impact tests, wherein the tensile performance is carried out according to GB / T1040.2-2006, the bending performance is carried out according to GB / T 934-2008, and the impact performance is carried out according to GB / T 1843-2008 . The antibacterial test and mildew test are carried out according to GB 21551.2-2010, and the antibacterial rate is tested according to the film method. The surface performance test is carried out by measuring the contact angle between the surface of the material and water. Anti-dust acceleratio...

Embodiment 3

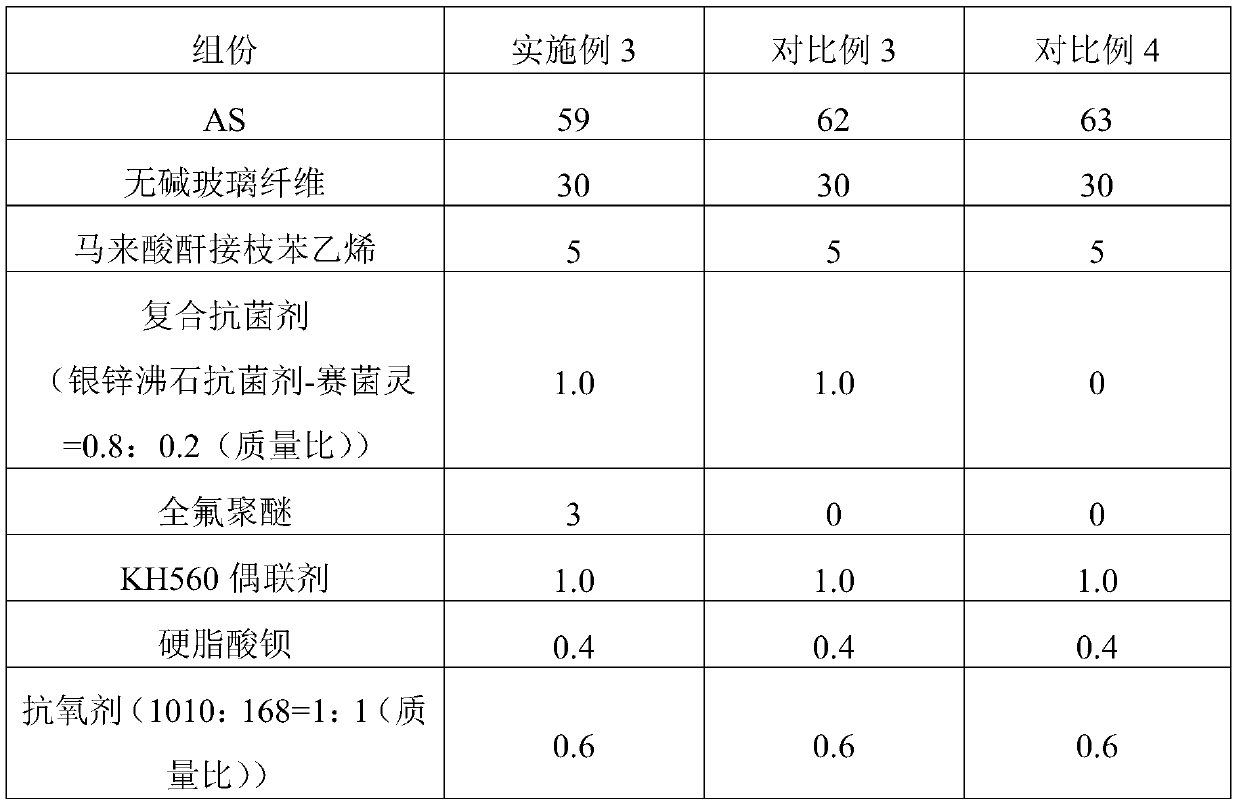

[0088] In this example, a cross-flow wind impeller material for an air conditioner is prepared. The specific formula is shown in Table 4.

[0089] Table 4. Raw materials and proportions of cross-flow wind wheel materials (mass fraction unit: %)

[0090]

[0091] The raw materials (except glass fiber) according to the above ratio are mixed and stirred evenly and then added to the extruder hopper. The pretreated glass fiber is introduced from the opening of the extruder barrel separately, and all components are heated and sheared by the extruder Cutting and mixing, plasticizing into a uniform melt, cooling and pelletizing after passing through the die, to obtain the required air-conditioning cross-flow wind wheel material. Wherein, the temperature range of each section of the extruder is 210-250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com