Method and system for treating high-fluorine high-hardness wastewater by two-stage two-phase fluidized bed through self crystallization

A self-crystallization and fluidized bed technology, applied in chemical instruments and methods, water/sewage treatment, water treatment parameter control, etc., can solve the problems of increasing sludge impurities, high moisture content, large sludge volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

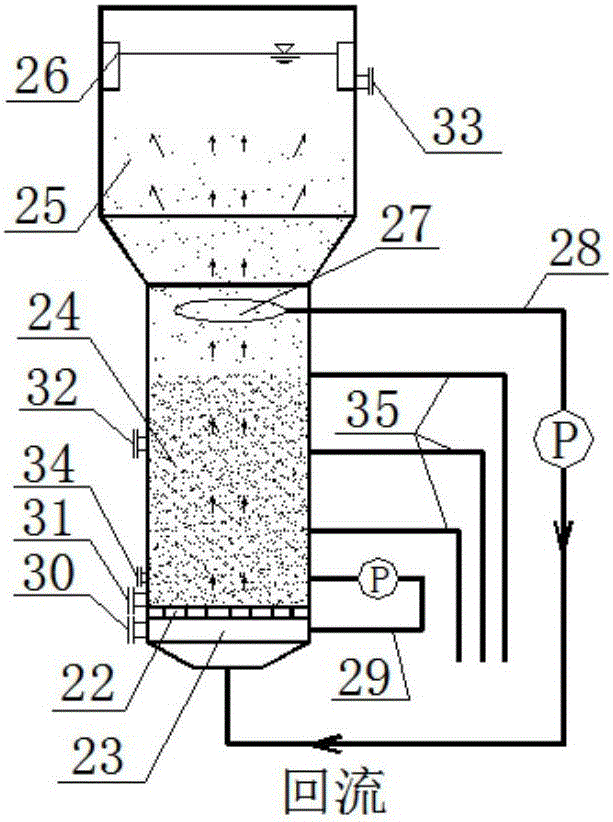

[0209] This embodiment provides a self-crystallization fluidized bed reactor, the structural representation of the self-crystallization fluidized bed reactor is as follows figure 2 shown, which includes:

[0210] Reactor shell;

[0211] The water distributor 22 installed at the bottom of the reactor cylinder, when the reactor is running, the water distribution area 23 is below the water distributor 22, and the cavity above the water distributor 22 will form a fluidized bed 24;

[0212] A water collection weir 26 is arranged around the top of the reactor cylinder, and below the water collection weir 26 is a solid-liquid separation area 25, and an annular water collection pipe 27 is arranged between the solid-liquid separation area 25 and the fluidized bed 24;

[0213] The side wall of the reactor cylinder is provided with a water inlet 30, a slag discharge port 31, a dosing port 32, a water outlet 33, and a sampling pipe 35,

[0214] Wherein, the water inlet 30 and the slag ...

Embodiment 2

[0219] This embodiment provides a self-crystallization fluidized bed reactor, the structural representation of the self-crystallization fluidized bed reactor is as follows image 3 shown, which includes:

[0220] Reactor shell;

[0221] The water distributor 22 installed at the bottom of the reactor cylinder, when the reactor is running, the water distribution area 23 is below the water distributor 22, and the cavity above the water distributor 22 will form a fluidized bed 24;

[0222] A water collection weir 26 is arranged around the top of the reactor cylinder, and below the water collection weir 26 is a solid-liquid separation area 25, and an annular water collection pipe 27 is arranged between the solid-liquid separation area 25 and the fluidized bed 24;

[0223] The side wall of the reactor cylinder is provided with a water inlet 30, a slag discharge port 31, a dosing port 32, a water outlet 33, and a sampling pipe 35,

[0224] Wherein, the water inlet 30 and the slag d...

Embodiment 3

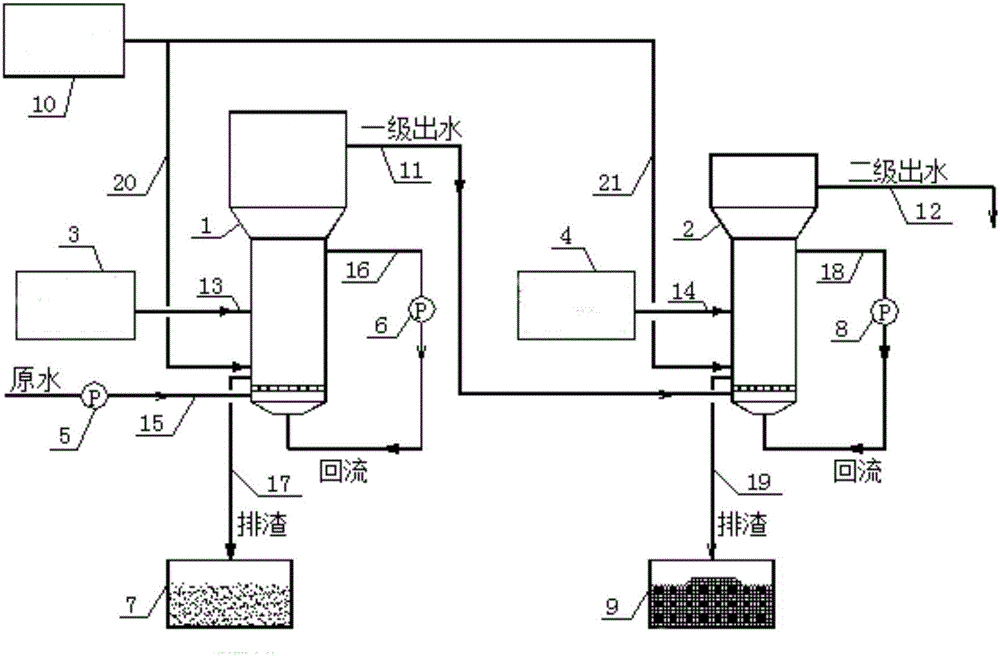

[0230] This embodiment provides a two-stage two-phase fluidized bed self-crystallization system for treating high-fluorine and high-hardness wastewater. The structural diagram of the system is as follows figure 1 Shown, it comprises: two self-crystallizing fluidized bed reactors described in embodiment 1 (or embodiment 2): respectively denoted as primary reactor 1 (wherein, the water circulation system of primary reactor comprises primary reaction Circulation pump 6 and return pipeline 16, return pipeline 16 comprises outlet pipeline and return pipeline), secondary reactor 2 (wherein, the water circulation system of secondary reactor comprises secondary reactor circulation pump 8 and return pipe 18, the return pipeline 18 includes the water outlet pipeline and the water return pipeline); the medicament A dosing device 3, the medicament B dosing device 4, the primary material pool 7 and the secondary material pool 9;

[0231] Wherein, the raw water pool is connected to the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com