Telescopic belt conveying two-way loading/unloading machine

A belt conveyor and belt conveying technology, applied in the direction of conveyor, conveyor objects, loading/unloading, etc., can solve the problems of economical and fast loading and unloading, convenience and safety, multiple loading and unloading, waste of resources, etc., and improve the working environment. and labor conditions, avoid secondary loading and unloading and handling, reduce the effect of waste of funds and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

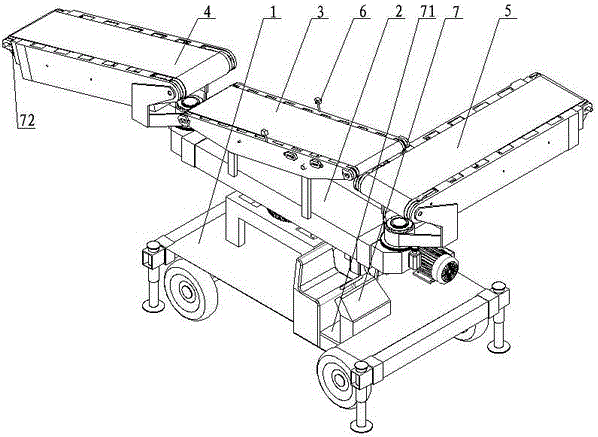

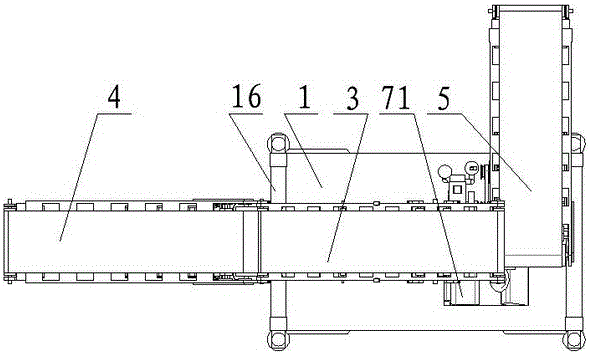

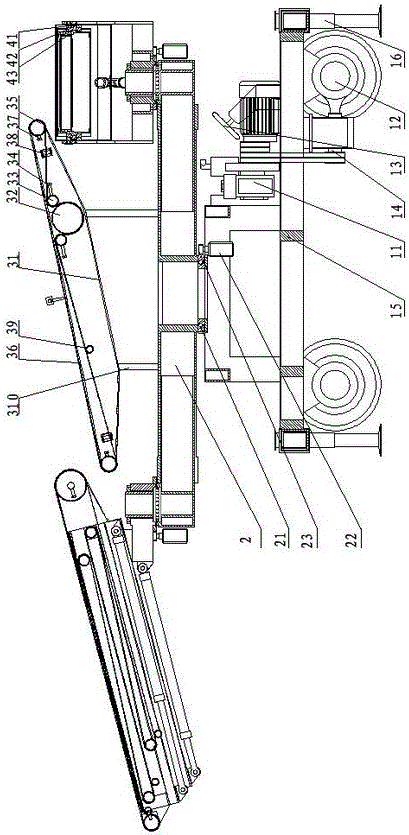

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention consists of a vehicle 1 with a walking function, a pivoting arm 2 with a swing function, an intermediate transition conveyor 3 that can be transported obliquely, a belt conveyor-4 with amplitude-changing, swing and telescopic functions, and a belt conveyor Machine two 5, a metering device 6 with metering, display and storage, and printing functions and its manipulation control system 7 are composed. Described pivoting arm 2 is fixed on the vehicle frame 15, belt conveyor one 4 and belt conveyor two 5 are installed at the two ends of pivoting arm 2, the middle part of pivoting arm 2 is obliquely installed intermediate transition conveyor 3, metering device 6 is fixedly installed on Intermediate transition conveyor 3 or belt conveyor one 4 and belt conveyor two 5; the vehicle 1 is used as the loading and unloading mechanism of the loading and unloading machine, which can reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com