Protection film capable of being attached to cambered-surface edge and preparation method of protection film

A technology of protective film and laminating arc, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., and can solve problems such as poor stability, poor experience, and poor functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

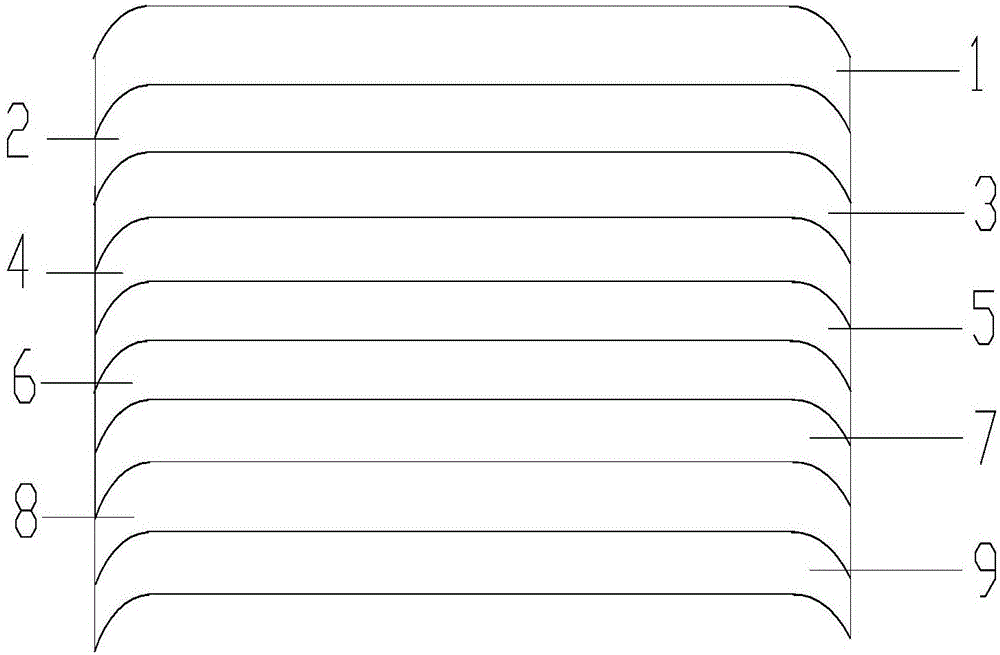

[0027] Such as figure 1 As shown, a protective film that can be attached to the edge of the arc surface, the protective film is a layered structure, including the first PE layer, the first PET release film layer, self-healing coating, TPU layer, OCA layer, PET layer, silica gel layer, second PET release film layer, second PE layer. The TPU layer is a TPU film, the TPU film has a hardness of 85A and a thickness of 100 μm. The self-healing coating is a polyethylene terephthalate coating; the thickness of the self-healing coating is 25 μm. The OCA layer is an OCA double-sided adhesive layer, and the viscosity of the OCA double-sided adhesive layer is 200g; the OCA double-sided adhesive layer is an optical grade acrylic adhesive. The thickness of the OCA layer is 15 μm. The thickness of the silica gel layer is 30 μm, and the viscosity is 80 g. The PET layer is a PET film, and the thickness of the PET layer is 50 μm.

[0028] The preparation method of the protective film that ...

Embodiment 2

[0036] Such as figure 1As shown, a protective film that can be attached to the edge of the arc surface, the protective film is a layered structure, including the first PE layer, the first PET release film layer, self-healing coating, TPU layer, OCA layer, PET layer, silica gel layer, second PET release film layer, second PE layer. The TPU layer is a TPU film, the TPU film has a hardness of 85A and a thickness of 120 μm. The self-healing coating is a polyethylene terephthalate coating; the thickness of the self-healing coating is 25 μm. The OCA layer is an OCA double-sided adhesive layer, and the viscosity of the OCA double-sided adhesive layer is 200g; the OCA double-sided adhesive layer is an optical grade acrylic adhesive. The thickness of the OCA layer is 20 μm. The thickness of the silica gel layer is 30 μm, and the viscosity is 90 g. The PET layer is a PET film, and the thickness of the PET layer is 50 μm.

[0037] The preparation method of the protective film that c...

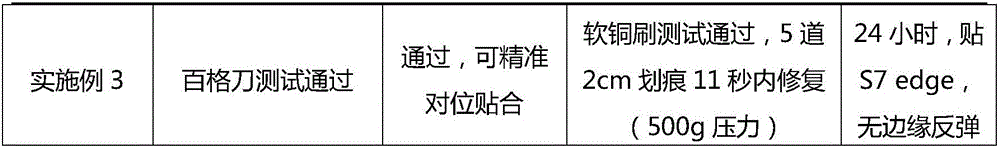

Embodiment 3

[0045] Such as figure 1 As shown, a protective film that can be attached to the edge of the arc surface, the protective film is a layered structure, including the first PE layer, the first PET release film layer, self-healing coating, TPU layer, OCA layer, PET layer, silica gel layer, second PET release film layer, second PE layer. The TPU layer is a TPU film, the hardness of the TPU film is 85A, and the thickness is 150 μm. The self-healing coating is a polyethylene terephthalate coating; the thickness of the self-healing coating is 25 μm. The OCA layer is an OCA double-sided adhesive layer, and the viscosity of the OCA double-sided adhesive layer is 200g; the OCA double-sided adhesive layer is an optical grade acrylic adhesive. The thickness of the OCA layer is 25 μm. The thickness of the silica gel layer is 30 μm, and the viscosity is 100 g. The PET layer is a PET film, and the thickness of the PET layer is 50 μm.

[0046] The preparation method of the protective film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com