Bridge switching type tool, and operating method and application thereof

An operation method, an opening and closing technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as thermal changes, low efficiency, and cumbersome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment, this case is described in further detail.

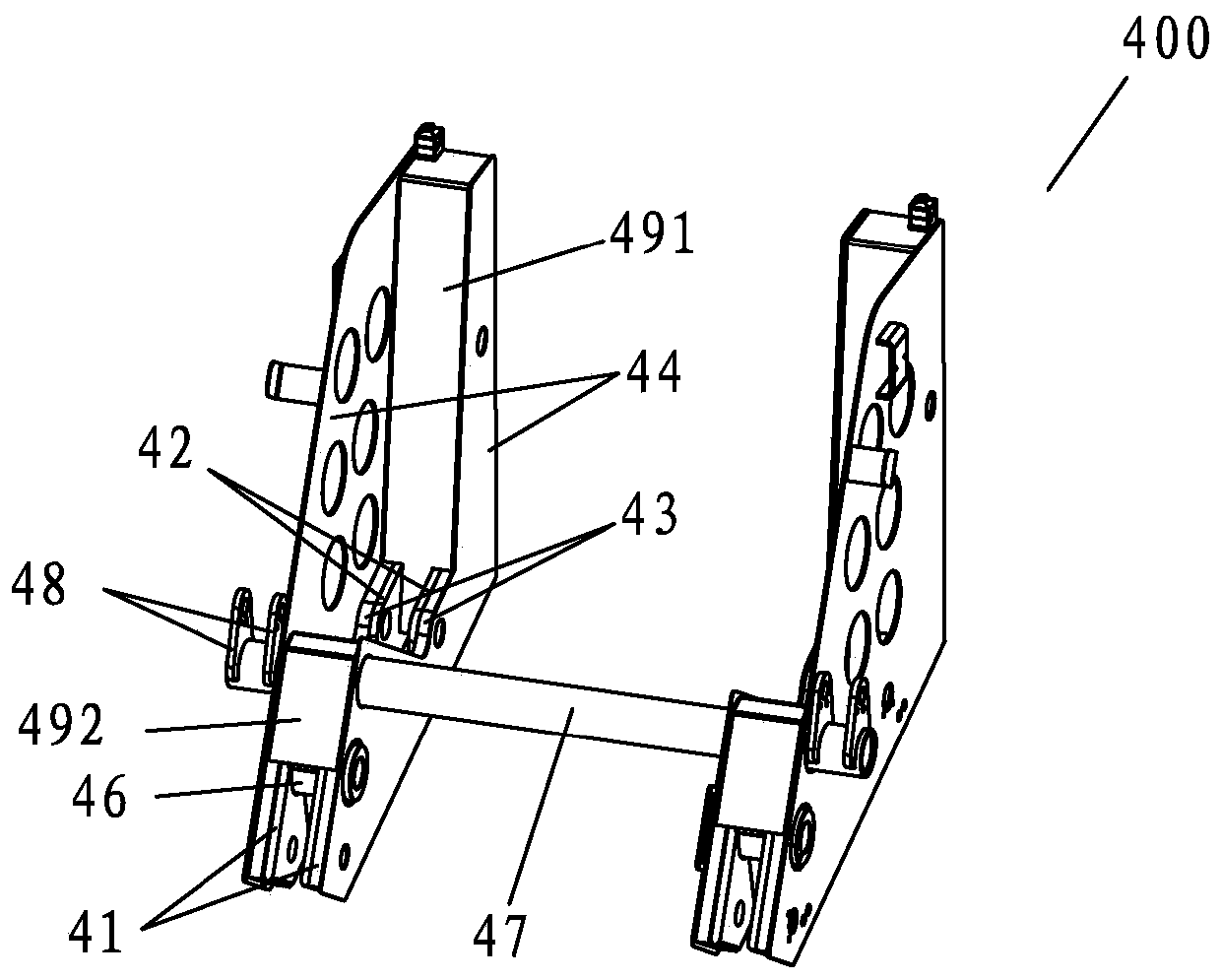

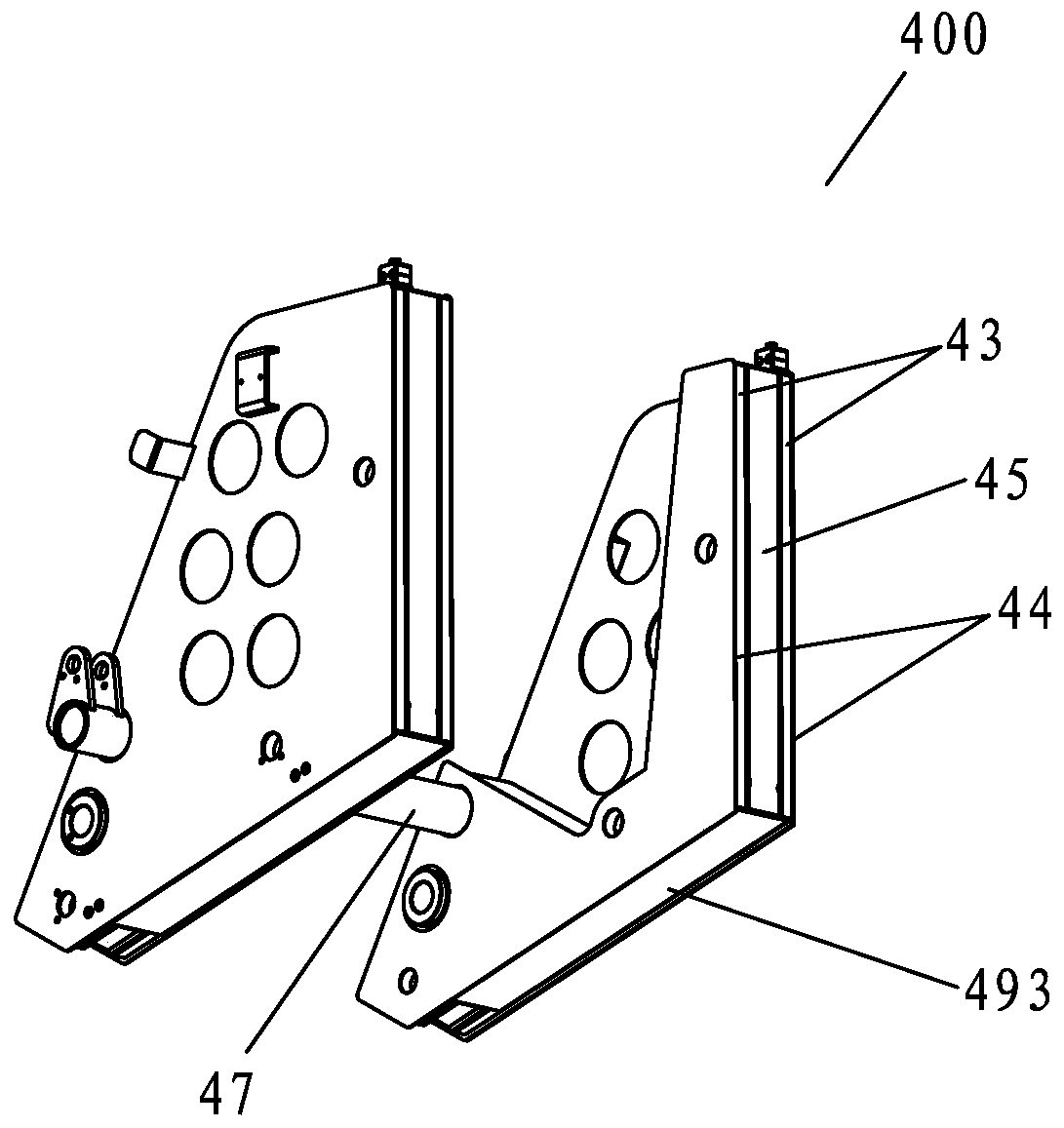

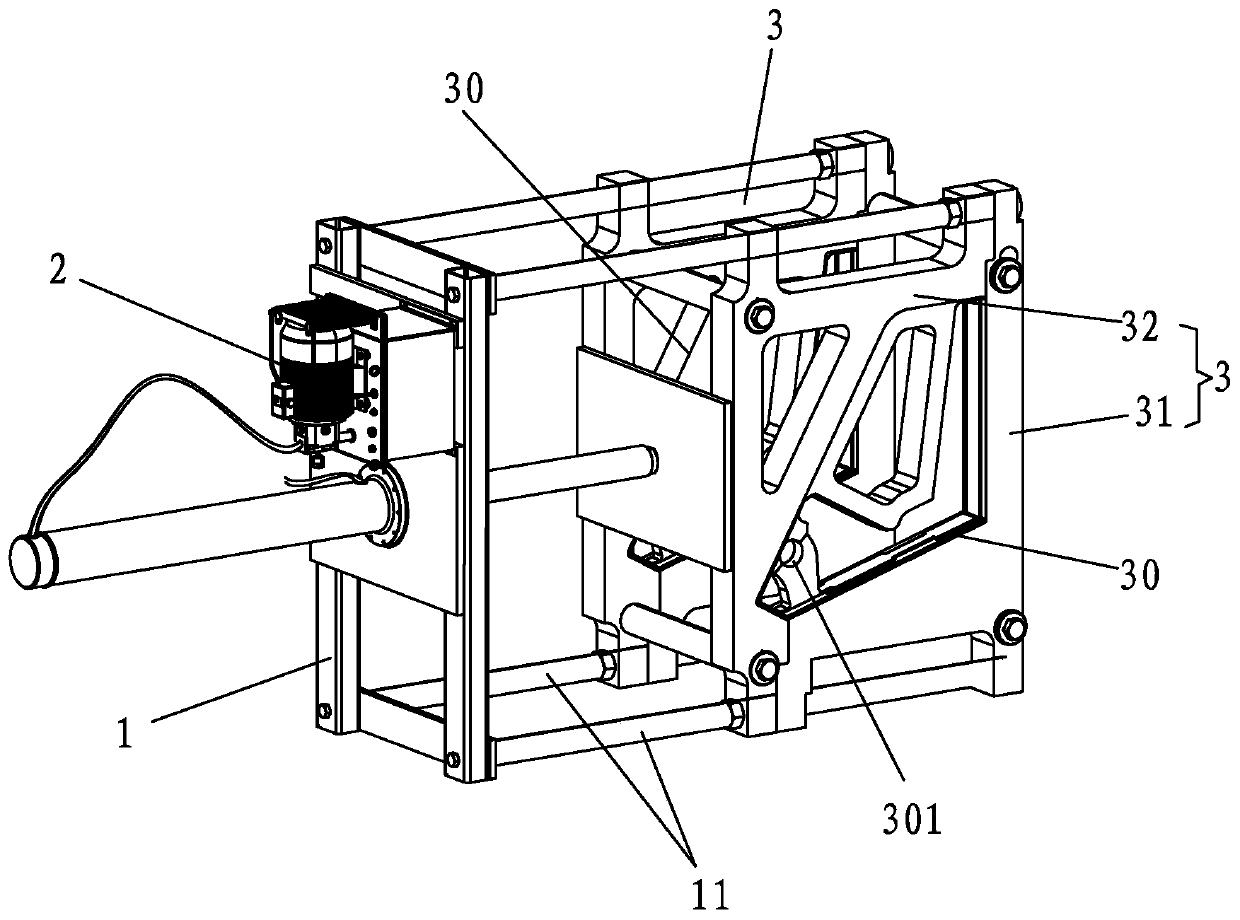

[0045] This case involves a bridge-type opening and closing tooling, such as Figure 3-6 As shown, it includes a tooling frame 1 , an opening and closing drive unit 2 installed on the tooling frame 1 and at least two groups of tooling modules 3 .

[0046] Tooling modules 3 are provided with at least two groups, which are arranged in a row on the tooling frame 1, and the arrangement positions are arranged according to the structure of the workpiece to be tooled. Each set of tooling modules 3 includes a fixed module 31 and a movable module 32 that match each other, and the opening and closing drive unit 2 drives the fixed module 31 and the movable module 32 to perform mold opening and closing actions. In a preferred embodiment, the fixed mold 31 is fixedly installed on the tooling frame 1, the movable mold 32 is movably installed on the tooling frame 2, and the opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com