Precise preforming device and method for small-section tunnel in quantitative expansion and contraction model test

A model test and small cross-section technology, which is used in measurement devices, cross-section drawing, instruments, etc., can solve the problems of small support and adjustment devices, difficult to operate, and difficult to maintain the same size, and achieves the effect of ensuring convenience and standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

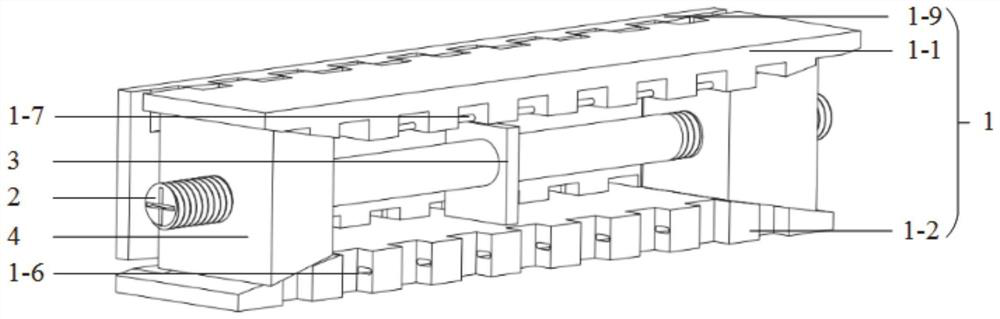

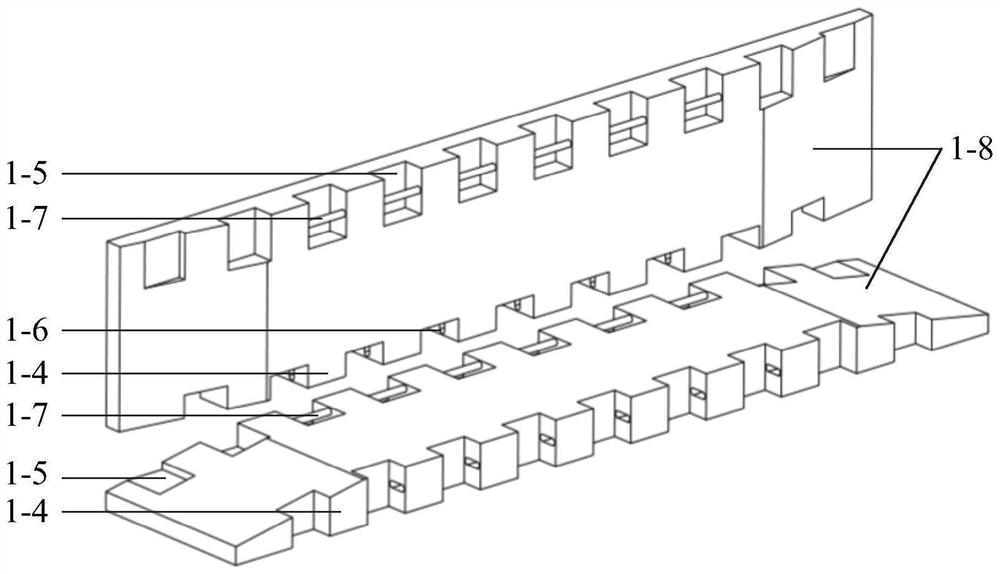

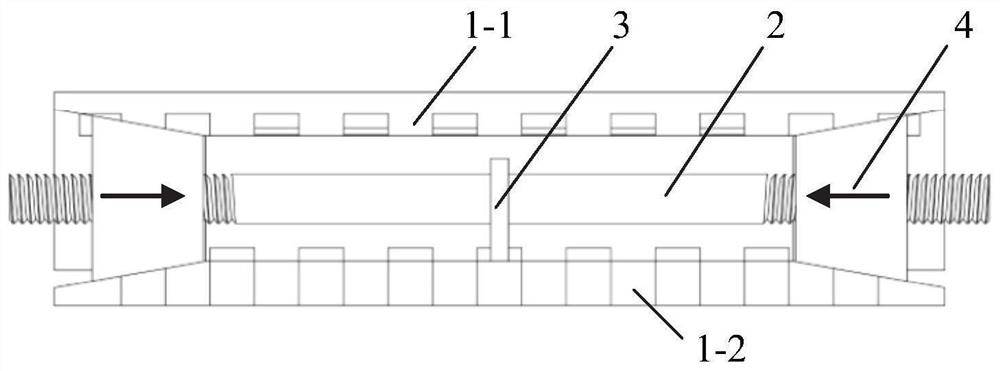

[0053] This embodiment discloses a quantitative expansion and contraction model test small-section tunnel precise preforming device, such as Figure 1-Figure 2 As shown, it includes a support mechanism and an adjustment mechanism, the support mechanism is used to be arranged inside the similar material filled during the test to form a tunnel, and the adjustment mechanism can drive the expansion and contraction of the support mechanism.

[0054] In this embodiment, the support mechanism 1 is used to be arranged along the longitudinal direction of the tunnel, and adopts a cylindrical structure formed by a plurality of support plates that are plugged and connected in sequence and then closed into a ring and formed with open ends at both ends. The top of the tunnel is the top direction, the bottom is the bottom direction, and the two sides of the tunnel are the left and right directions, respectively.

[0055] According to the test requirements, this embodiment needs to open a tun...

Embodiment 2

[0084] This embodiment discloses the working method of the quantitative expansion and contraction model test small-section tunnel precise preforming device described in Embodiment 1, which includes the following steps:

[0085] Step 1: Lay a thin layer of bentonite at the bottom of the preset tunnel, and place a PTFE board with the same size as the bottom surface of the tunnel, because bentonite has strong adhesion, good plasticity, good demoulding, and air permeability It has good characteristics, and the PTFE plate has high lubricity, so the setting of the bentonite and the PTFE plate can ensure the convenient demoulding of the support mechanism and the integrity of the forming tunnel.

[0086] Step 2: Adjust the external size of the support mechanism to the set size of the preset tunnel through the adjusting rod, and place it on the PTFE plate at the preset tunnel position.

[0087] Step 3: Arrange PTFE plates with the same size as the left and right sides of the preset tun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com