Self-induction repairing resin matrix composite structure and preparing repairing method

A composite material and repairing resin technology, which is applied in the field of self-induction repairing resin-based composite material structure and preparation and repair, can solve the problems of multiple additional weight gain and complex system interface, and achieves reduction of system complexity, small decrease in mechanical properties, and structural Simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

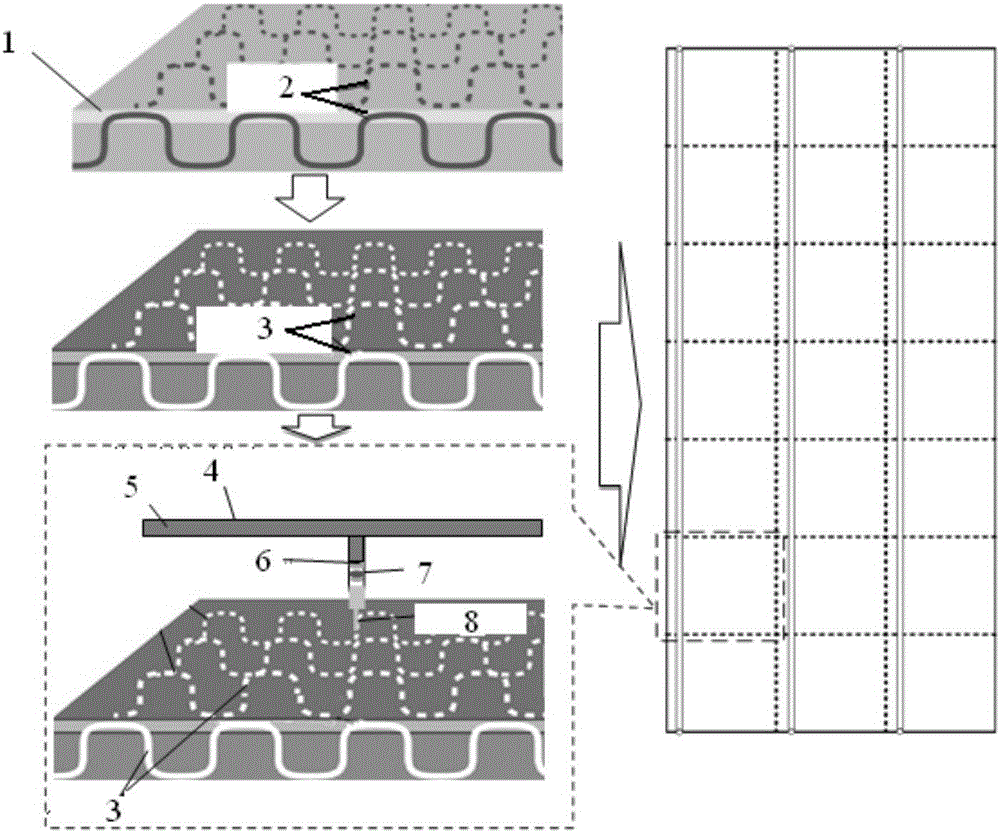

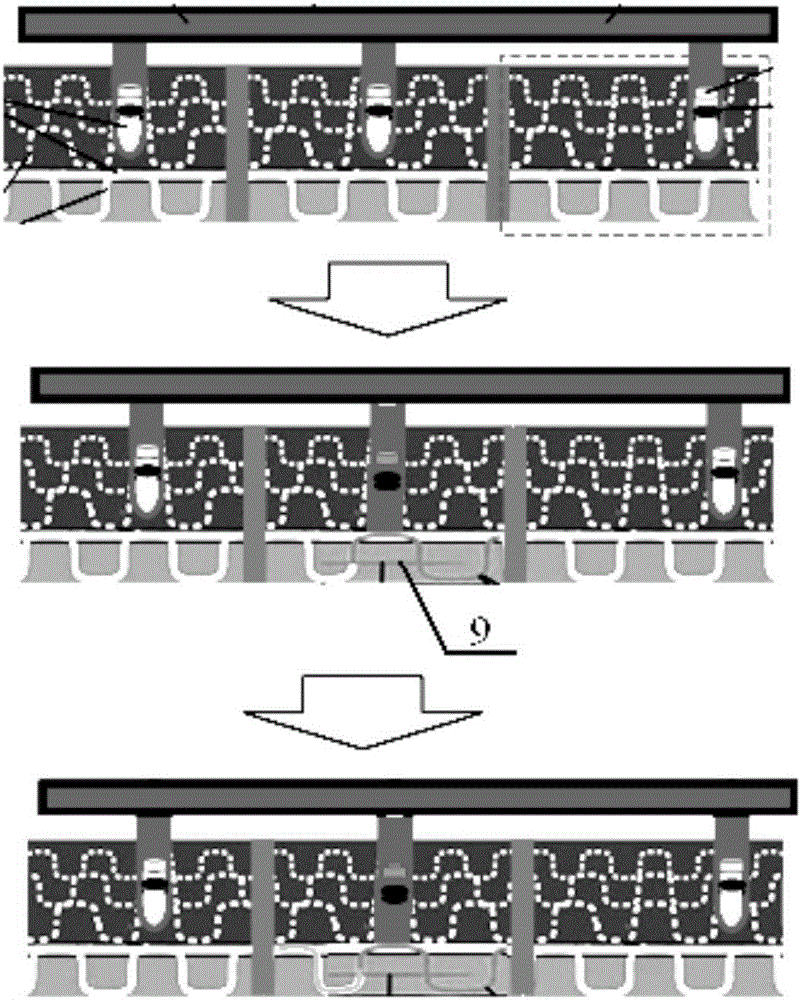

[0036] A method for preparing a self-inductively repairing resin-based composite material structure as described above, the method comprising the following steps:

[0037] Step 1. Formation of hollow vessels without heterogeneous walls

[0038] Put the sacrificial wire 2 into the dry fiber fabric or prepreg layup, the resin of the composite material is cured and formed, and then the sacrificial wire is removed by chemical or physical methods and the vascular network between the composite material units is cut off. Each composite material unit of 1 forms a hollow vessel 3 that is sensitive to cracks and has no heterogeneous walls;

[0039] Step 2. Install the restoration agent delivery pipeline

[0040] On the surface of the resin-based composite material 1, a repairing agent delivery pipeline 4 is installed, and the repairing agent delivery pipeline 4 communicates with each composite material unit through a number of connecting pipes, and a check valve 6 is installed in the c...

Embodiment 1

[0048]Embodiment 1 Preparation of glass fiber reinforced resin-based composite material GFRP containing hollow vessels

[0049] Lay the prepreg according to the layup sequence set as follows: the position of the pre-embedded line PSL [0 / 0 / 0 / 0 / PSL / 0 / 0 / 0 / 0], the diameter of the pre-embedded line is 100- 500 μm. Add pre-embedded lines between the set layers, with an interval of 1-20mm between the pre-embedded lines, and then continue to lay the glass fabric reinforced epoxy resin SW280 / 3218 prepreg of the set layer, and use the autoclave process to form composite materials. The autoclave curing process is: vacuumize at room temperature, the vacuum degree is not less than -0.095MPa, heat to 60°C, hold for 0.5h, pressurize 0.3MPa, raise the temperature to 130°C at a heating rate of 1.5°C / min, keep the temperature for 2h, and naturally Cool to below 60°C and leave the tank. The pre-embedded thread was pulled out from the composite material to obtain a GFRP composite material conta...

Embodiment 2

[0050] Example 2 Preparation of GFRP composites containing hollow vessels

[0051] Lay the prepreg according to the layup sequence set as follows: the position of the pre-embedded line PSL [45 / 0 / -45 / 90 / PSL / 45 / 0 / -45 / 90]s, the diameter of the pre-embedded line 100-500μm. Add pre-embedded lines between the set layers, the interval between the pre-embedded lines is 1-20mm, and the two layers of pre-embedded lines are staggered by 2-10mm, and continue to lay the glass fabric reinforced epoxy resin SW280 / 3218 prepreg of the set layer, Composite materials are molded by autoclave process. The autoclave curing process is: vacuumize at room temperature, the vacuum degree is not less than -0.095MPa, heat to 60°C, hold for 0.5h, pressurize 0.3MPa, heat up to 130°C at a heating rate of 1.5°C / min, keep the temperature for 2h, and naturally Cool to below 60°C and leave the tank. The pre-embedded thread was pulled out from the composite material to obtain a GFRP composite material containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity at room temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com