Full-contact one-piece toilet bowl body mold clamping and releasing method

A one-piece toilet and mold technology, which is applied in the field of ceramic manufacturing, can solve the problems of reduced yield, poor demoulding, and many molds, and achieve the effects of simple structure, improved body pass rate, and increased automation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

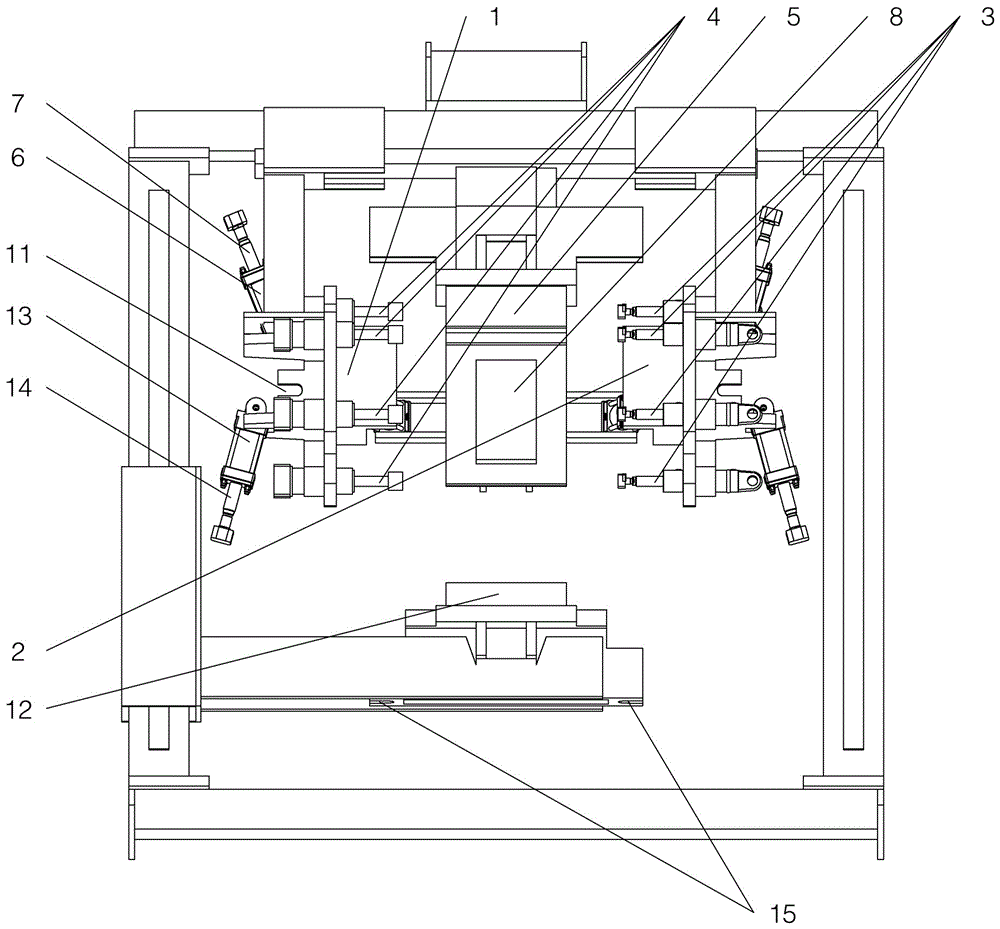

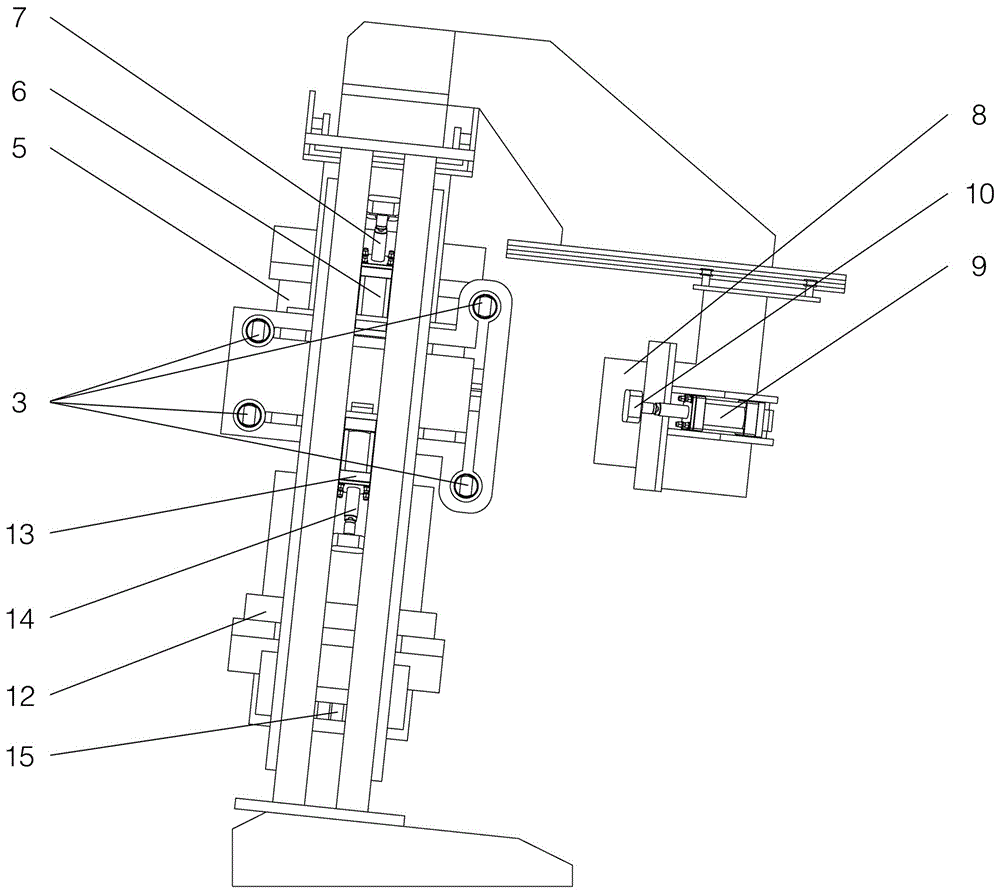

[0027] The embodiment of the present invention adopts such as figure 1 and figure 2 The high pressure grouting machine shown. Left mold 1, right mold 2, upper mold 5, front mold 8, lower mold 12 are respectively arranged on it, in addition, outside the press, mechanical arm also clamps mold small parts (not shown in the figure) ). When performing mold closing operations, the following steps are used:

[0028] Step 1: Side mold clamping, PLC controls the side mold clamping cylinder to quickly push the side molds 1 and 2 on the left and right sides t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com