Long pipe type part inner hole honing device and honing method thereof

A technology for honing and parts, which is applied to the inner hole honing machine and its honing field, can solve the problem of low processing quality, and achieve the effect of meeting quality requirements, being easy to process, and avoiding failure to honing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

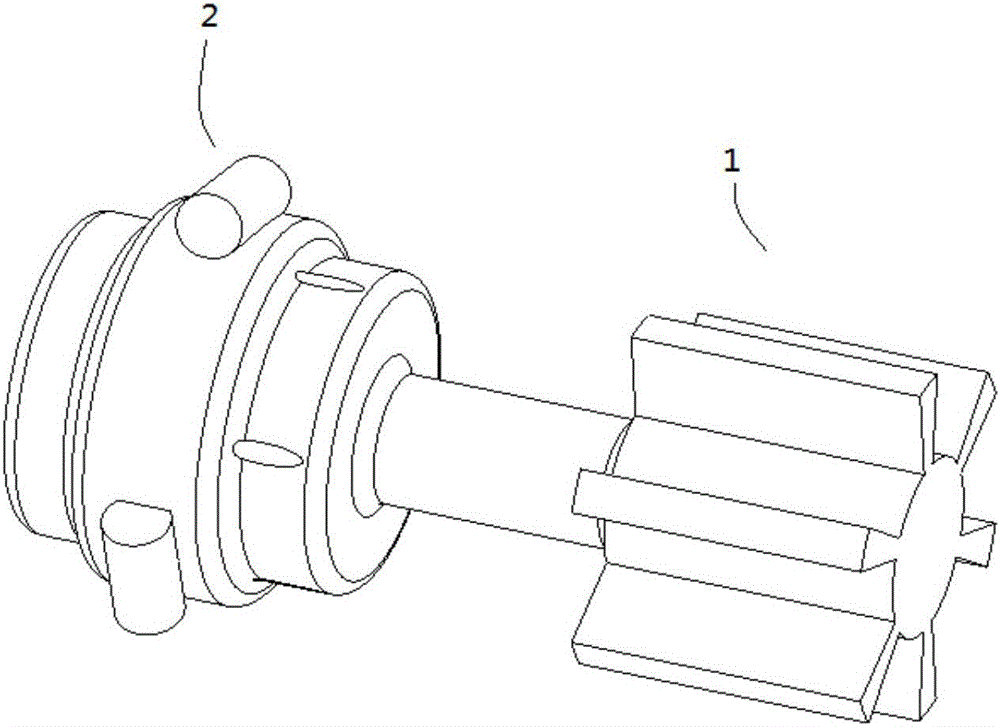

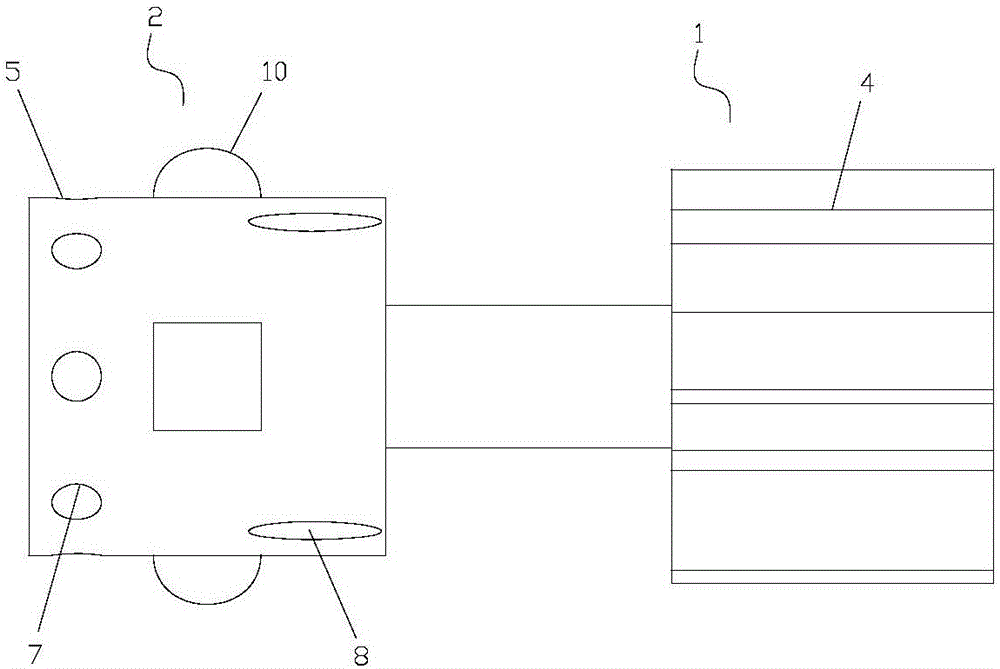

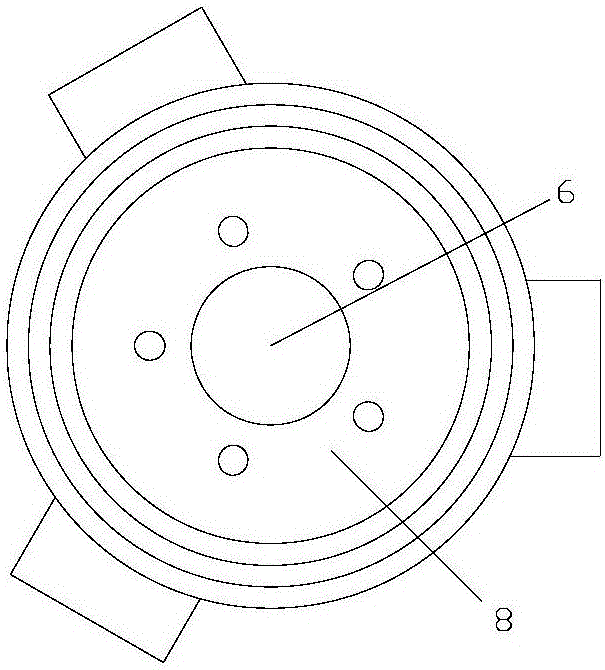

[0043] like Figure 1-5 As shown, a honing machine for the inner hole of a long tubular part includes a honing head assembly 1 and a honing brake assembly 2. Specifically, the honing head assembly includes an air motor 3 and a honing head 4 detachably fixed to the motor shaft. The moving assembly includes a casing 5, a brake arranged in the casing, and independent driving air passages and travel air passages. The casing is a cylinder with one end open and one end closed. The air motor enters the cylinder from the open end and is fixed with the cylinder. The driving air path is an axial air inlet 6 connected to the air motor at the closed end of the cylinder. Compressed air enters through the axial air inlet 6 to drive the air motor to rotate and then drive the honing head to work.

[0044] The advancing air passage is a plurality of inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com