A portable primer removal tool

A dismantling tool and portable technology, which is applied in the field of portable primer dismantling tools, can solve the problems that the tool slips out of the primer installation groove, cannot be removed from the primer, and the projectile body is fixed, etc., to achieve general performance enhancement, convenient carrying and field operations, and prevent loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

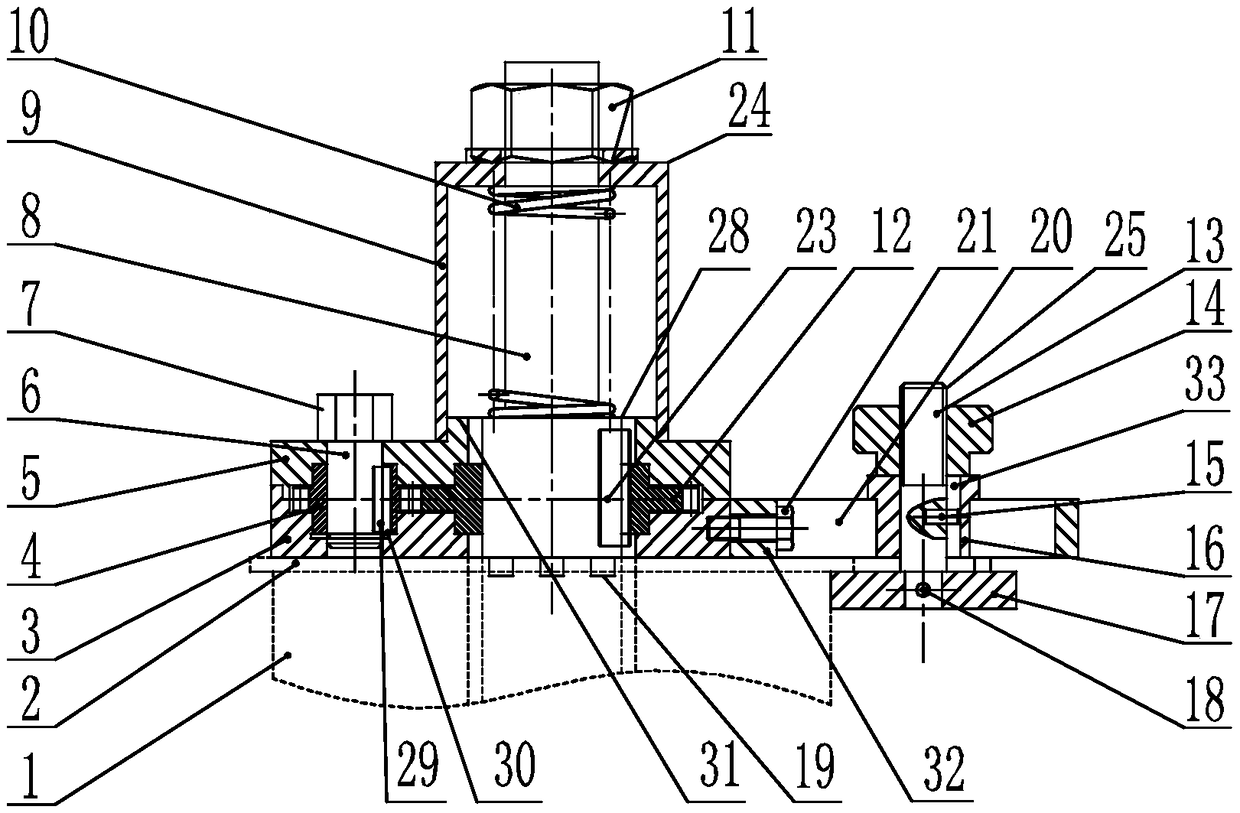

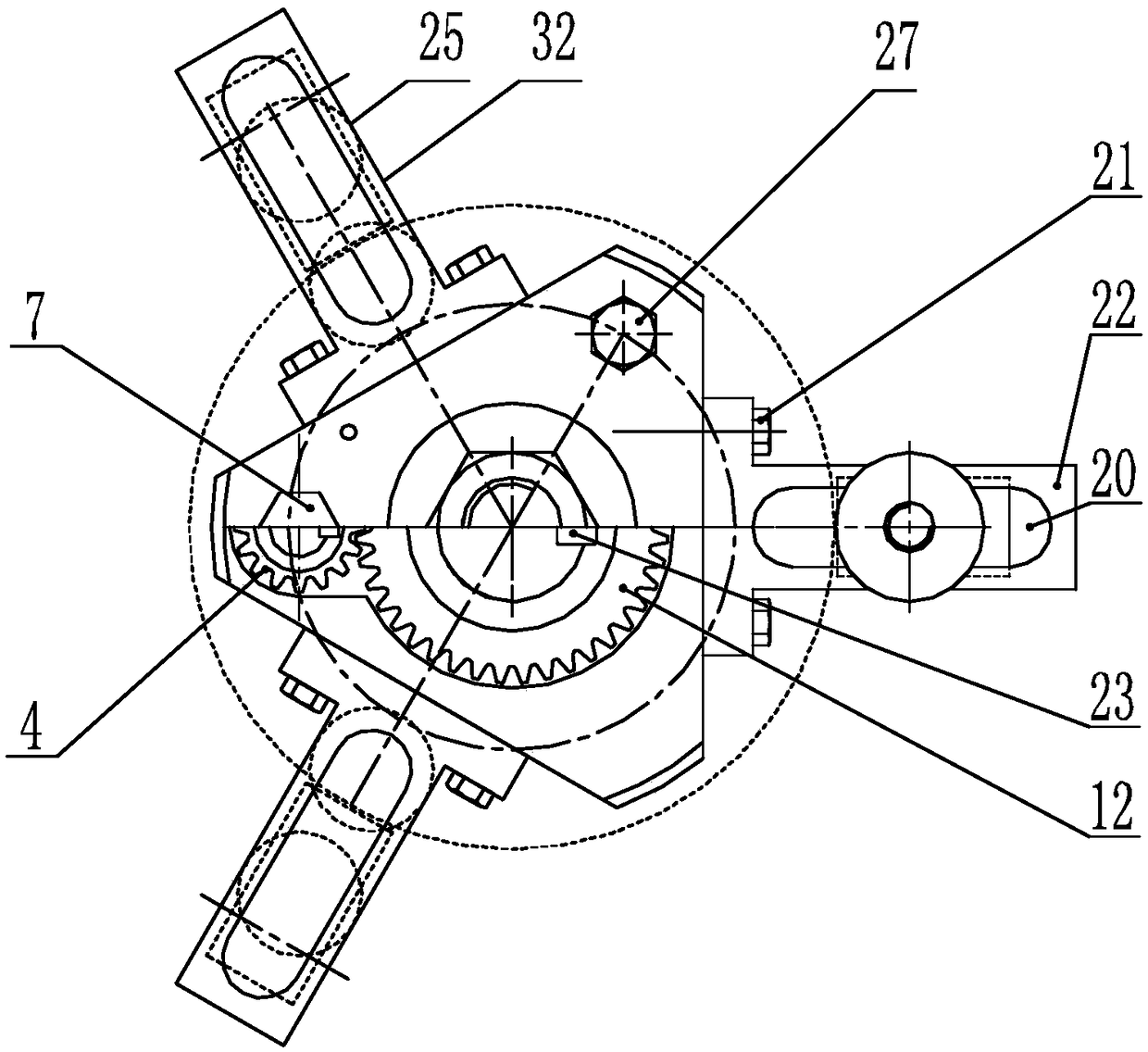

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 As shown in , the portable primer removal tool is used to remove the primer of different types of shells. Due to its small size, light weight and safe and convenient operation, it can be applied to any portable operation place.

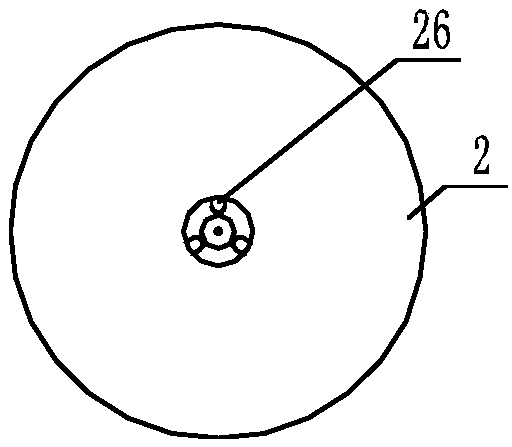

[0029] The portable primer removal tool includes a pressure applying device 24, a flat base plate 3 and a panel 5, the panel 5 is stacked on the base plate 3 and relatively fixed with the base plate 3; the outer periphery of the base plate 3 is fixedly provided with a sealing plate locking device 25 , The pressure applying device 24 is provided above the panel 5 . Wherein, the pressure applying device 24 is used to insert the primer installation groove 26 (see image 3 )’s toggle claw 19 exerts pressure. Since the primer is installed very firmly, the primer seal plate 2 connected to the bottom of the cartridge case 1 is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com