A complete set of welding equipment and working method for automatic vertical welding of LNG storage tank 9% Ni steel

A 9% ni, automatic technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of cable winding, welding torch rotation angle limited, inapplicability, etc., to achieve easy implementation, avoid poor weld quality, and weld high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

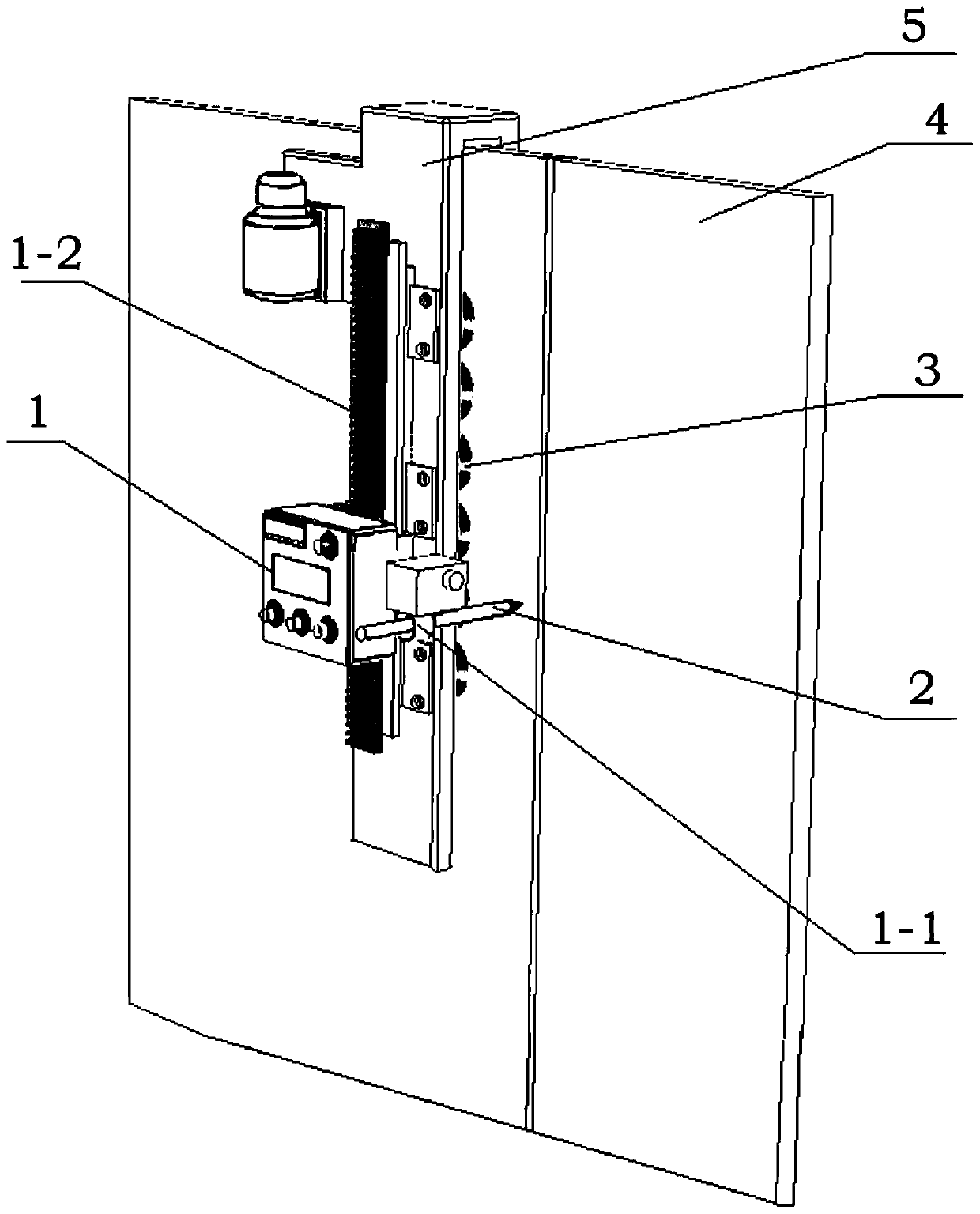

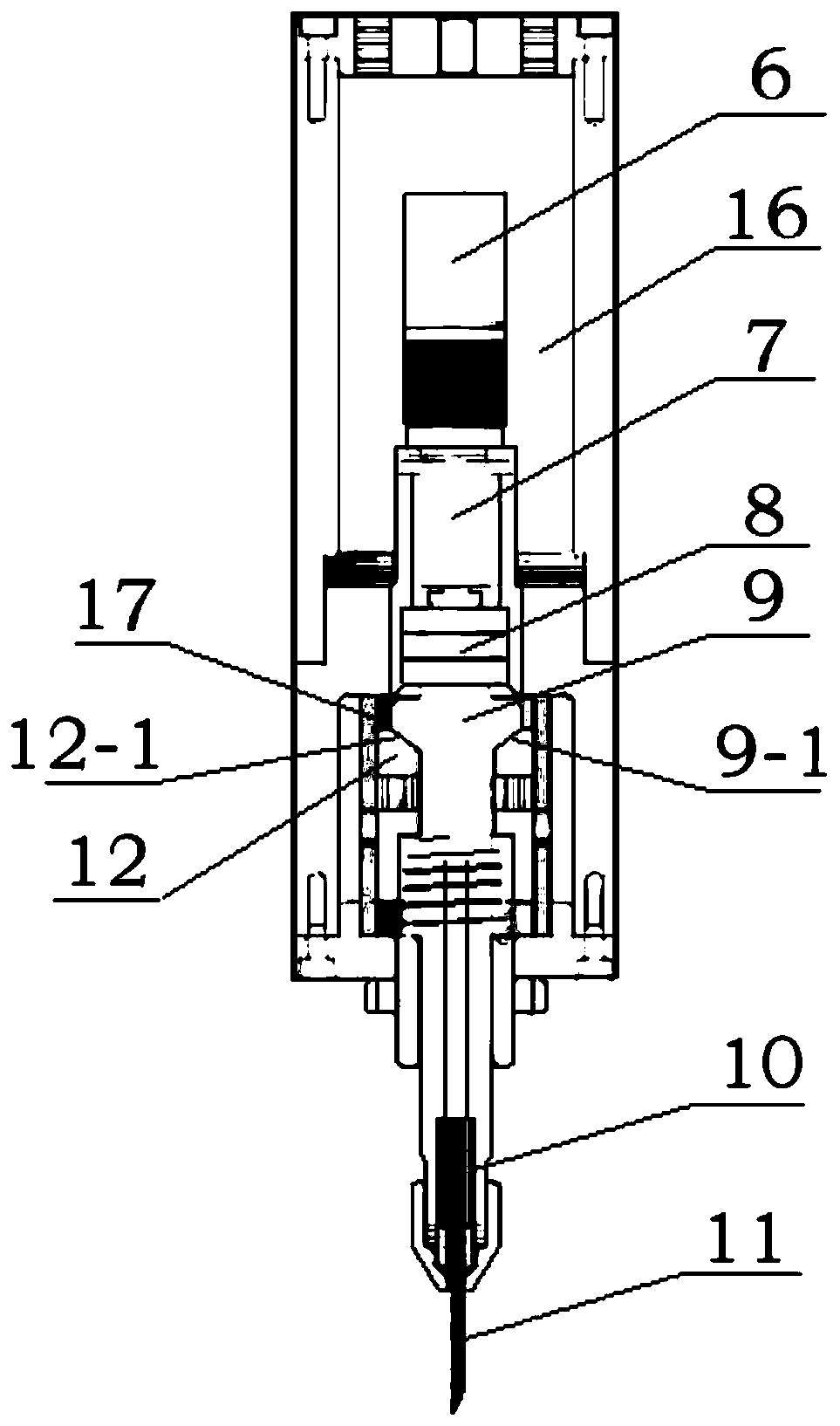

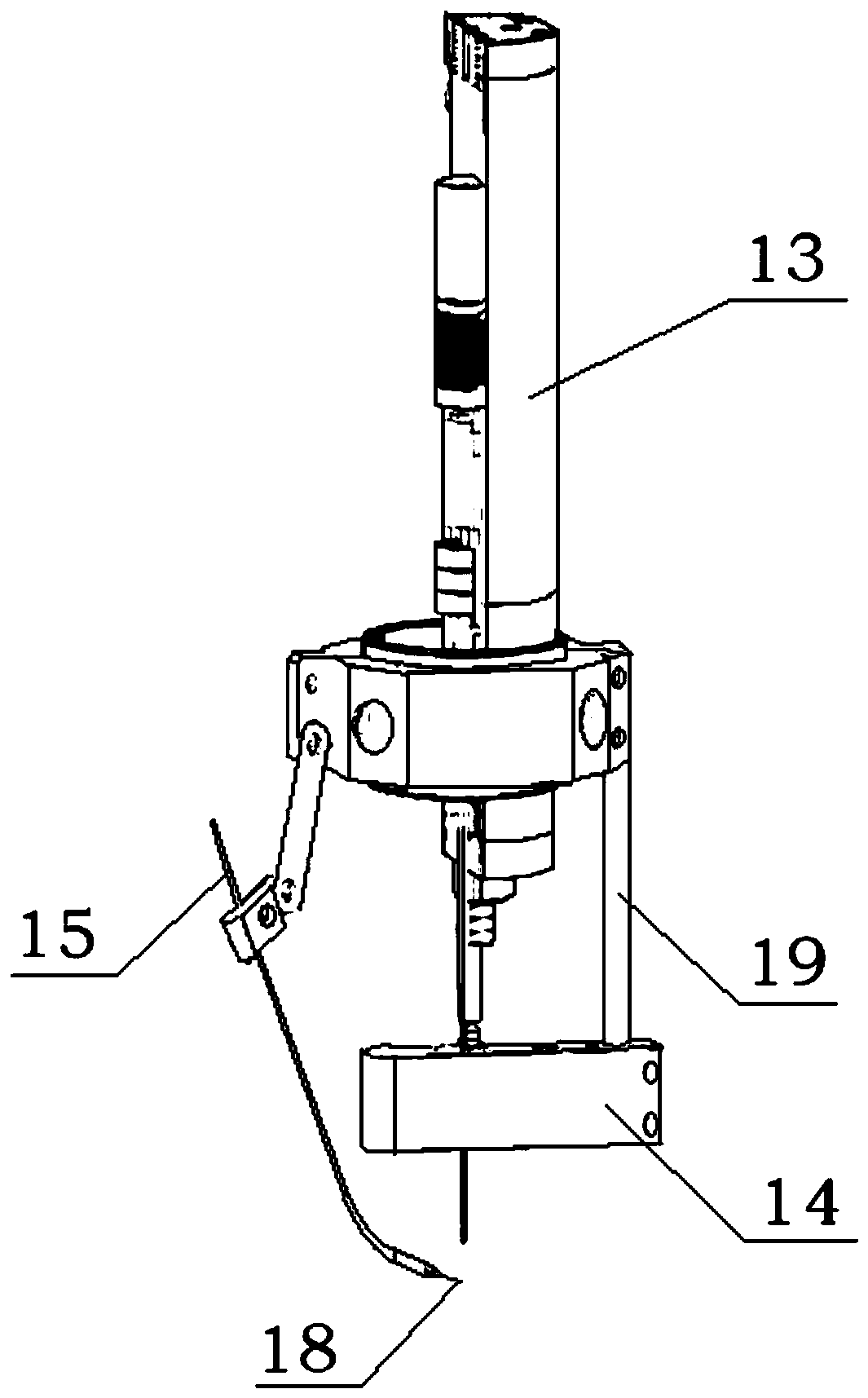

[0049] A complete set of welding equipment for automatic vertical welding of 9% Ni steel for LNG storage tanks, including a vacuum adsorption system, a welding trolley and a narrow gap rotary tungsten electrode welding torch; the vacuum adsorption system includes a wall-mounted suction plate, a vacuum pump, and the inner side of the wall-mounted suction plate There is a suction cup, the wall-mounted suction plate is suspended on the weldment, the suction cup is connected with the vacuum pump, the wall-mounted suction plate is connected with the welding trolley; Gap rotary tungsten welding torches are connected; narrow gap rotary tungsten welding torches include a gun body with a central rotating shaft, a conductive system and a motor control box, the motor control box is connected with one end of the central rotating shaft, and the other end of the central rotating shaft is set There is a tungsten pole, and one end of the tungsten pole is a non-centrosymmetric tip; the conducti...

Embodiment 2

[0055] A complete set of welding equipment for automatic vertical welding of 9% Ni steel for LNG storage tanks, its structure is as described in Embodiment 1, the difference is that the motor is located in the support block, the motor is connected with the gun body through the support block, and the support block is an electric Support blocks for woodworking. The supporting part around the motor is processed with bakelite to ensure the insulation between the motor and the central shaft and prevent high-frequency breakdown.

Embodiment 3

[0057] A complete set of welding equipment for automatic vertical welding of 9% Ni steel for LNG storage tanks. Its structure is as described in Example 1, the difference is that an inclined-plane boss is provided on the outside of the central axis, and an inclined-plane groove is provided on the conductive block, and the inclined-surface is convex. The table is in contact with the slope groove. Make the central shaft and the conductive block have a taper contact, and when the central shaft rotates, the two complete the conduction in the rotation. The taper can increase the conductive contact surface to ensure stable and good conductivity under high welding current. The angle between the slope of the slope boss and the radial plane of the central axis is 35°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com