Automobile part cleaning device

A technology of auto parts and cleaning devices, which is applied in the field of parts cleaning, and can solve the problems of easily damaged cleaning barrels, ineffective cleaning of parts, incomplete cleaning, etc., and achieve the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

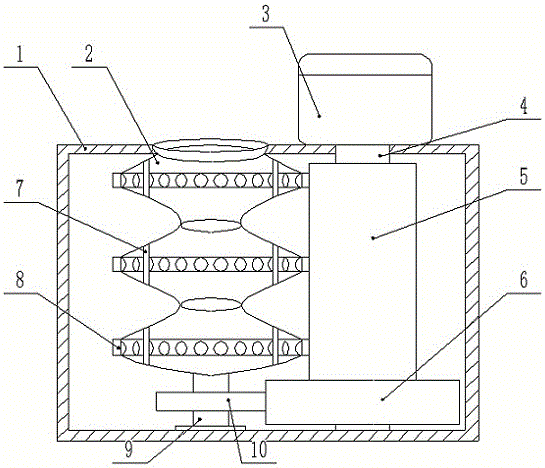

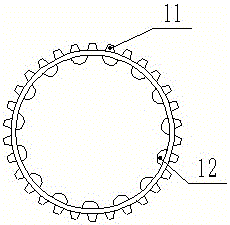

[0014] Description of reference numerals: casing 1, cleaning bucket 2, motor 3, transmission shaft 4, second gear 5, first gear 6, connecting column 7, stirring ring 8, driving shaft 9, driving gear 10, transmission gear 11, Stirring tooth 12.

[0015] Such as figure 1 The auto parts cleaning device shown includes a casing 1, a cleaning bucket 2 and a motor 3, the motor 3 is installed on the top of the casing 1, the cleaning bucket 2 is installed on the left side inside the casing 1, and a drain pipe is installed at the bottom of the casing 1 . The cleaning bucket 2 includes two cleaning units, the middle of each cleaning unit shrinks inwardly, and the top of the cleaning unit on the top is connected to the barrel mouth through the stirring ring 8, and the bottom of the cleaning unit on the bottom is connected to the bucket through the stirring ring 8 Bottom, bucket bottom is fixedly connected with driving shaft 9, and driving shaft 9 cooperates and is installed on the rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com