Cleaning equipment for clean aeroengine case

A technology for aero-engines and cleaning equipment, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of not being able to remove metal debris in the casing, hollow casing, corrosion, etc., and achieve It is easy to process and produce, popularize and apply, has a simple structure, and meets the effect of high cleanliness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The high-cleanliness cleaning equipment for casings of the present invention will be further described below through examples and in conjunction with the accompanying drawings.

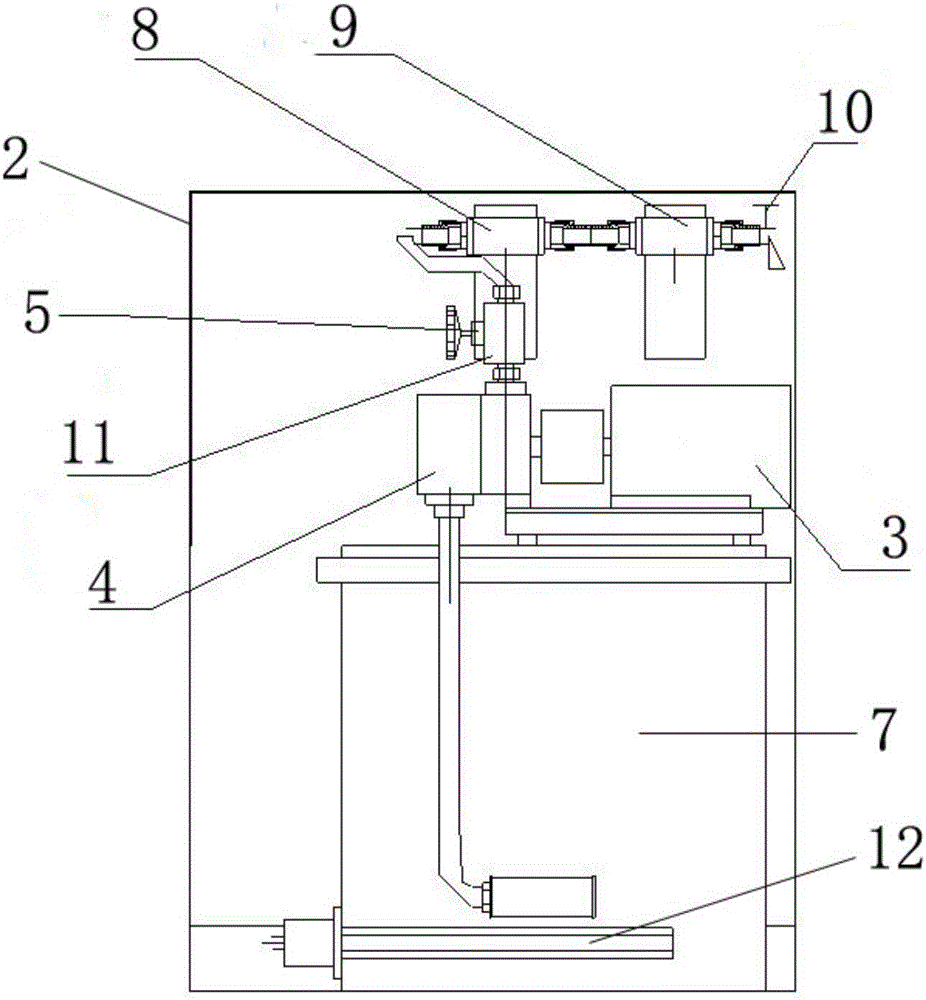

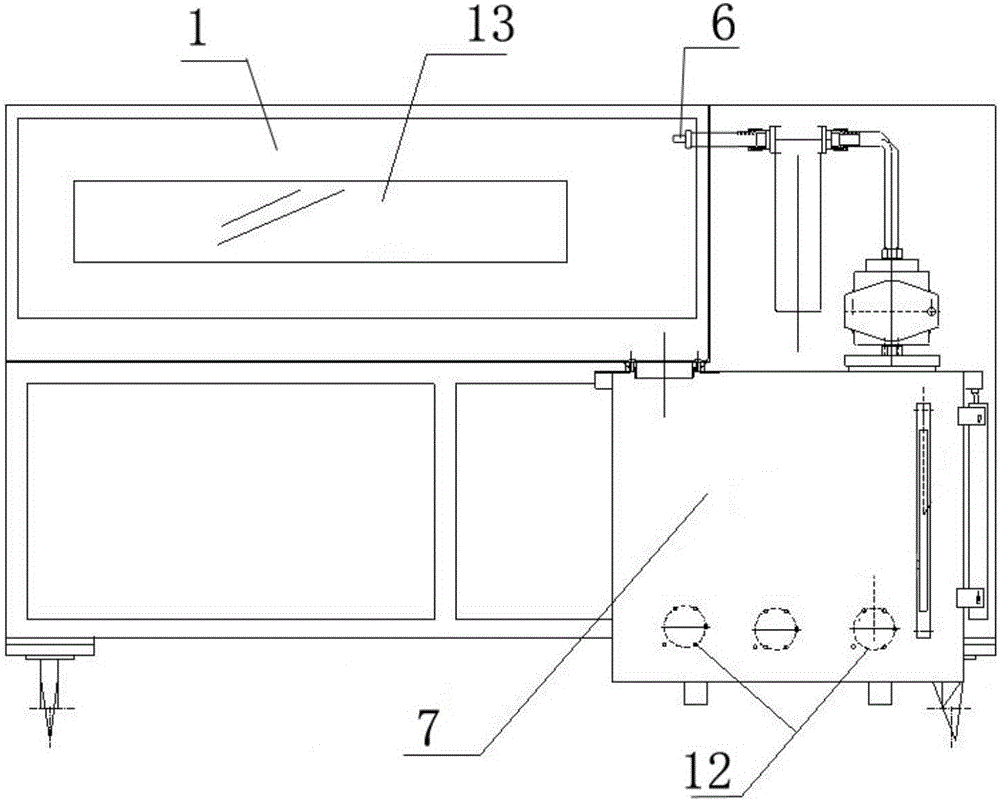

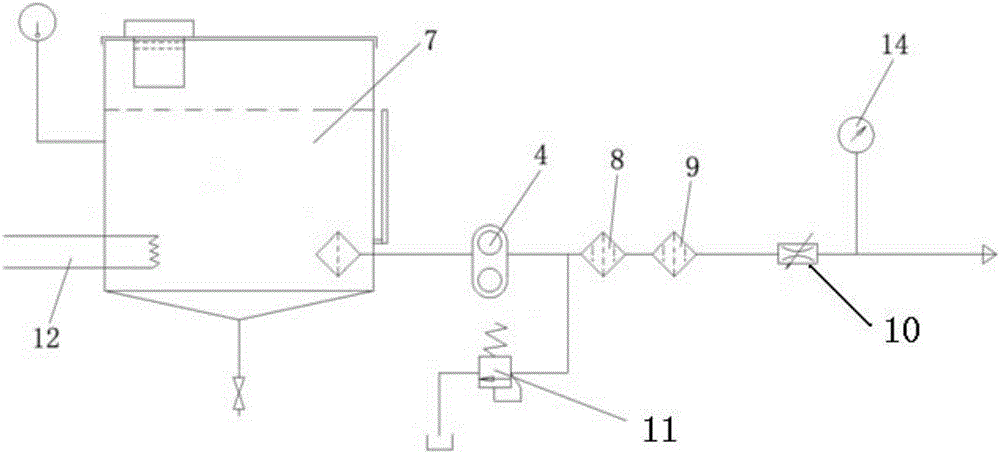

[0022] The cleaning equipment used to clean the aero-engine casing described in this embodiment, such as figure 1 -3, its composition includes, including cleaning room 1, cleaning oil storage and transportation facility room 2 and spraying gun 6; said cleaning room is provided with a cleaning platform for installing the casing to be cleaned, and is provided with on the wall of the cleaning room The spraying gun extends into the cleaning room window and the observation window 13; the cleaning oil storage and transportation room is provided with an oil storage tank 7 and an oil pump 4 whose inlet is connected to the space in the oil storage tank through a connecting pipe, so as to be arranged successively on the oil pump back on the delivery pipeline. Pressure overflow device 11, coarse oil filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com