Impurity removing device for rice processing

A technology of rice processing and electromagnetic heating roller, which is applied in the direction of separating solids from solids with airflow, magnetic separation, solid separation, etc., which can solve the problems of occupying plant space and large size, and achieve small plant space occupation and good structure Simple, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

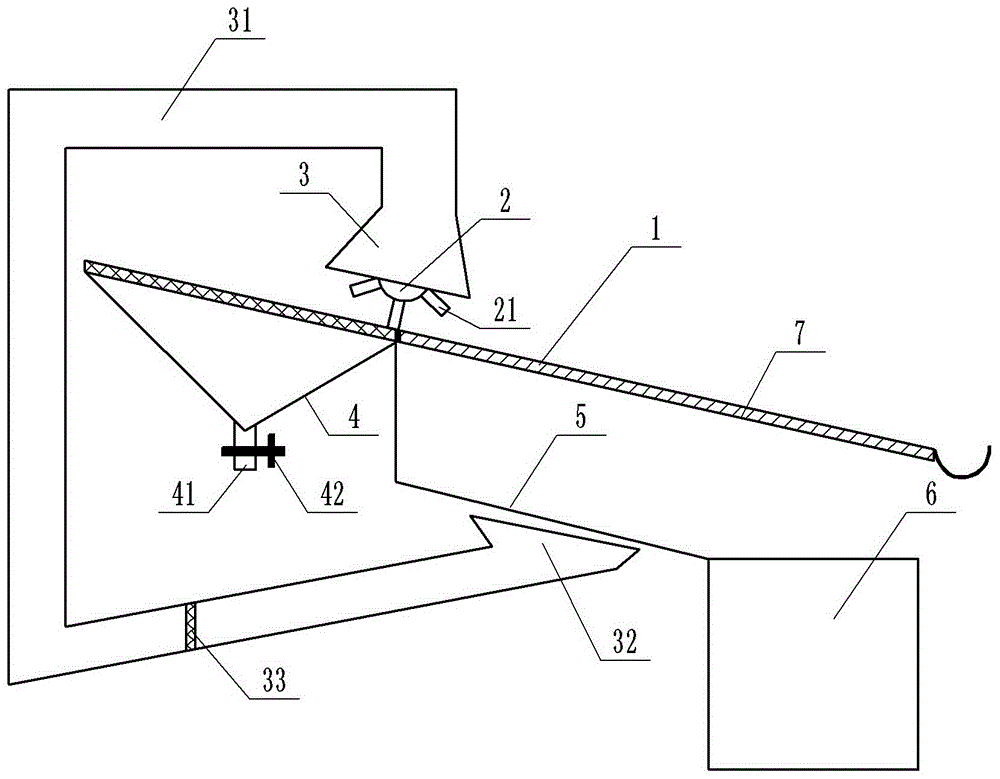

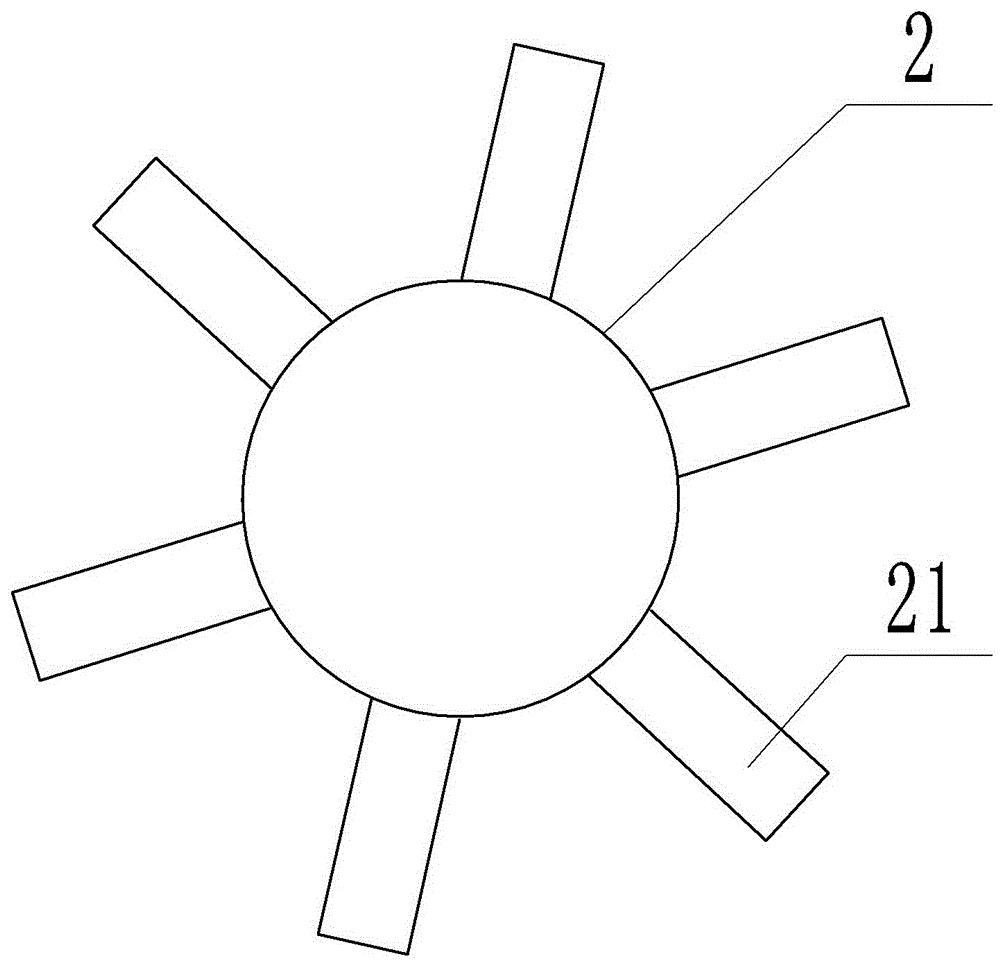

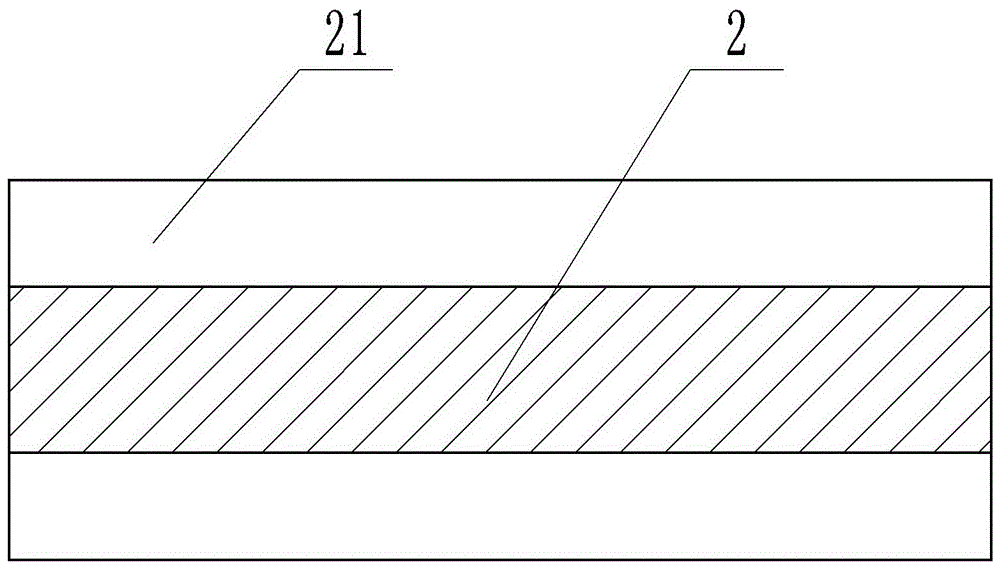

[0018] The reference signs in the drawings of the specification include: screen 1, electromagnetic heating roller 2, rolling blade 21, air suction port 3, pipe 31, air outlet 32, dust collection filter 33, collecting box 4, discharge pipe 41, Valve 42, inclined slide plate 5, grain storage bin 6, groove 7.

[0019] like figure 1 As shown, the impurity removal device for rice processing includes an electromagnetic heating roller 2, a motor, an air suction port 3 and a screen 1, and the screen 1 is arranged obliquely. The left side of the screen 1 is a small screen mesh, and the right side is a large screen. Sieve mesh, the right end of the sieve mesh 1 is provided with a groove 7 for collecting impurities. The bottom left side of screen cloth 1 is provided with collection box 4, and collection box 4 is funnel-shaped, and the lower end of collection box 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com