Method and device for preparing reverse osmosis membrane capable of resisting biological pollution

A technology of anti-biological pollution and reverse osmosis membrane, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of short service life, no antibacterial and bactericidal effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

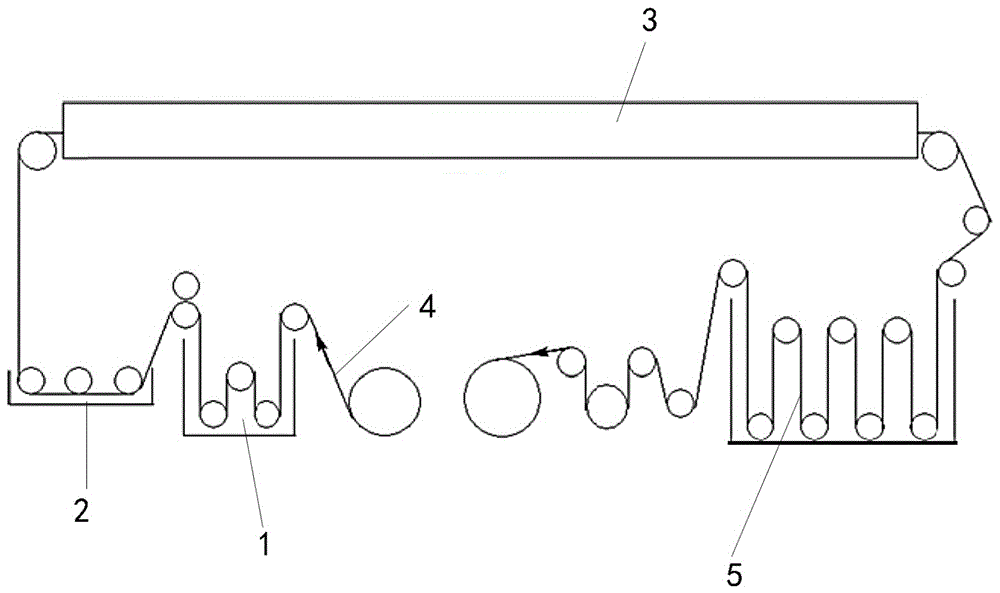

Image

Examples

Embodiment 1

[0027] A method for preparing an anti-biological fouling reverse osmosis membrane, comprising the following steps: passing the reverse osmosis membrane substrate through an ethylene glycol ethyl acrylate organic phase containing 1% propenylguanidine at a speed of 0.1m / min In the process, the solvent used in the organic phase is N,N-dimethylacetamide, and then passes through the ammonium persulfate solution containing 2% of the organic phase at a speed of 0.1m / min, and the solution also contains a mass fraction of 5% NaCl, after the cross-linking reaction, it is dried in a 50°C oven, and finally wind-cooled before winding.

Embodiment 2

[0029] A method for preparing an anti-biological fouling reverse osmosis membrane, comprising the following steps: passing the reverse osmosis membrane substrate through the organic phase of ethylene glycol ethyl acrylate containing 1% aminoacrylic acid at a speed of 0.1m / min , the solvent used in the organic phase is N,N-dimethylacetamide, and then passed through the ammonium persulfate solution containing 2% of the mass fraction of the organic phase at a speed of 0.1m / min, and the solution also contains a mass fraction of 5% NaCl, after the cross-linking reaction, it is dried in a 50°C oven, and finally wind-cooled and wound.

Embodiment 3

[0031] A method for preparing an anti-biological fouling reverse osmosis membrane, comprising the steps of: passing the reverse osmosis membrane substrate through an acrylic acid amino-2-methyl-propane containing 1% propenylguanidine at a speed of 0.2 m / min In the sulfonic acid organic phase, the solvent used in the organic phase is dimethyl sulfoxide, and then passes through the ammonium persulfate solution containing 3% of the organic phase with a mass fraction at a speed of 0.2m / min, and the solution also contains a mass fraction of 5% NaCl, after the cross-linking reaction, it is dried in a 50°C oven, and finally wind-cooled before winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com