Treatment apparatus and treatment process of dust-bearing organic waste gas

A technology for organic waste gas and treatment equipment, which is applied in auxiliary pretreatment, dispersed particle filtration, and dispersed particle separation, etc. It can solve problems such as the inability to ensure efficient and stable operation of the device, real-time monitoring of inoperable status, easy deviations and failures in operation, etc. , to achieve the effect of efficient and thorough dust filtration, convenient overall operation and low operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

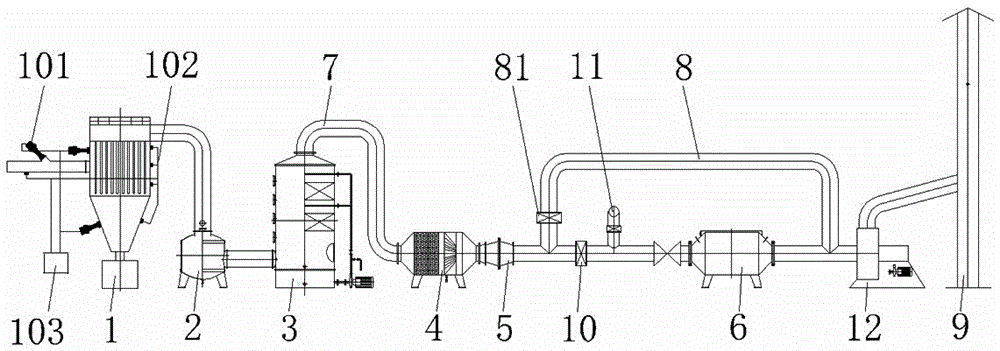

[0037] like figure 1 As shown, a treatment device for dust-containing organic waste gas in this embodiment includes: dust collector 1, buffer tank 2, liquid absorption tower 3, water removal device 4, flame arrester 5, activated carbon adsorption box 6, waste gas pipe 7. Emergency release pipe 8, discharge system 9, ventilation valve 10, automatic supplementary air valve 11, fan 12, fire and explosion suppression device 101, composite fire sensor 102, central control room 103 and emergency release valve 81.

[0038] The connection relationship of the above-mentioned components is as follows: the waste gas pipe 7 is successively provided with a dust collector 1, a buffer tank 2, a liquid absorption tower 3, a water removal device 4 and a flame arrester 5; The activated carbon adsorption box 6 and the emergency release pipe 8 are connected, and the exhaust gas pipe 7 between the flame arrester 5 and the activated carbon adsorption box 6 is provided with a ventilation valve 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com