Method for preparing calcium gluconate injection

A technology for calcium gluconate and injection, which is applied in the field of preparation of calcium gluconate injection, which can solve the problems of reduced solubility, etc., and achieve the effects of enhanced stability, increased dissolution aiding effect, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

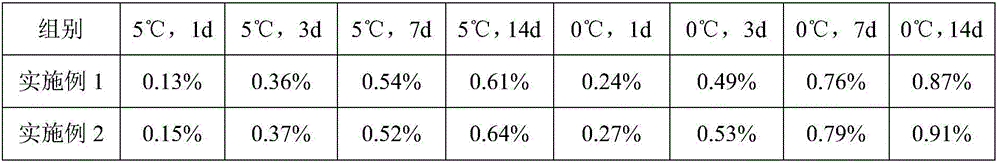

Examples

Embodiment 1

[0011] ①Take 90L of water for injection, add 200g of sodium acetate, 500ml of glacial acetic acid, and 3560g of calcium acetate, stir to dissolve, heat to boiling, add 11kg of calcium gluconate, stir to dissolve; ②Adjust the pH value to 6.01 with sodium hydroxide, add 200g Activated carbon, add water for injection to 100L, stir and circulate for adsorption for 20 minutes; ③Filtrate to remove carbon, filter with 0.45μm, 0.22μm, 0.22μm filters in sequence until qualified; Bacteria, light inspection, packaging.

Embodiment 2

[0013] ①Take 90L of water for injection, add 100g of sodium acetate, 300ml of glacial acetic acid, and 1560g of calcium acetate, stir to dissolve, heat to boiling, add 9kg of calcium gluconate, stir to dissolve; ②Adjust the pH value to 5.93 with sodium hydroxide, add 200g Activated carbon, add water for injection to 100L, stir and circulate for adsorption for 20 minutes; ③Filtrate to remove carbon, filter with 0.45μm, 0.22μm, 0.22μm filters in sequence until qualified; Bacteria, light inspection, packaging.

Embodiment 3

[0015] ① Take 90L of water for injection, add 150g of sodium acetate, 300ml of glacial acetic acid, and 3560g of calcium acetate, stir to dissolve, heat to boiling, add 10kg of calcium gluconate, stir to dissolve; ②Adjust the pH value to 5.97 with sodium hydroxide, add 200g Activated carbon, add water for injection to 100L, stir and circulate for adsorption for 20 minutes; ③Filtrate to remove carbon, filter with 0.45μm, 0.22μm, 0.22μm filters in sequence until qualified; Bacteria, light inspection, packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com