Caterpillar-type lotus seed shellershelling machine

A crawler-type, shelling machine technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of inability to align the lotus seeds, poor adaptability, and the lotus seeds are not peeled, so as to ensure the processing quality, improve production efficiency, Solve the effect of easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

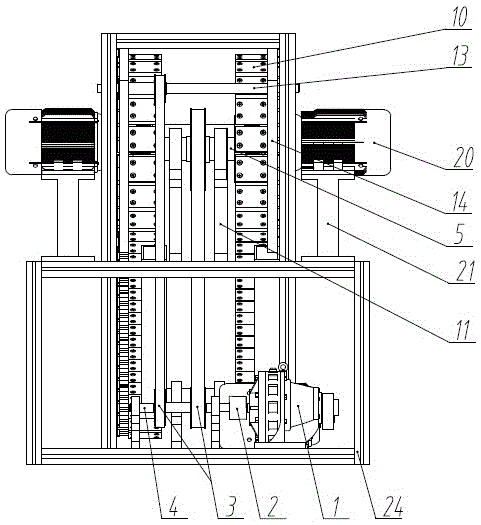

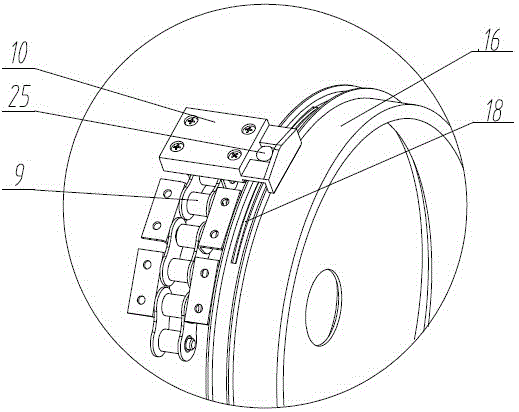

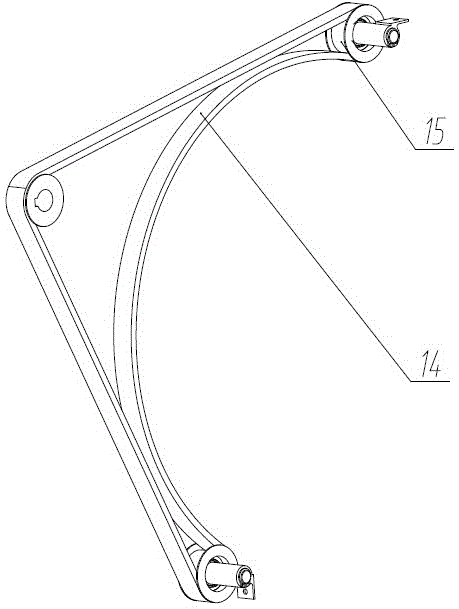

[0026] Such as Figure 1-Figure 10 As shown, a crawler type lotus seed peeling machine of the present invention, a bearing seat support frame 11 and a drive motor 1 are installed under the front end of the frame 24, a drive shaft 4 is installed on the bearing seat support frame 11, and one end of the drive shaft 4 passes through a coupling. Shaft device 2 links to each other with driving motor 1, and synchronous belt 3 is installed on the driving shaft 4; It is characterized in that: it comprises 2 groups of peeling mechanisms, and this peeling mechanism is that rail support frame 12 is installed on both sides of frame 24 middle, The support plate 10 on the track support frame 12 top sliding contact chain 9, described support plate 10 one end is provided with pressing belt guide groove 26, and the middle part of pressing belt guide groove is provided with lotus opening 27, and support plate 10 Arrange and install on each link of the chain 9, the chain 9 is engaged with a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com