Baby pigeon fattening feed and preparation method thereof

A production method and feed technology, applied in animal feed, animal feed, Lactobacillus, etc., can solve problems such as residues and antibiotic abuse, and achieve the effects of improving enzyme activity, improving digestibility, and increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of the first additive

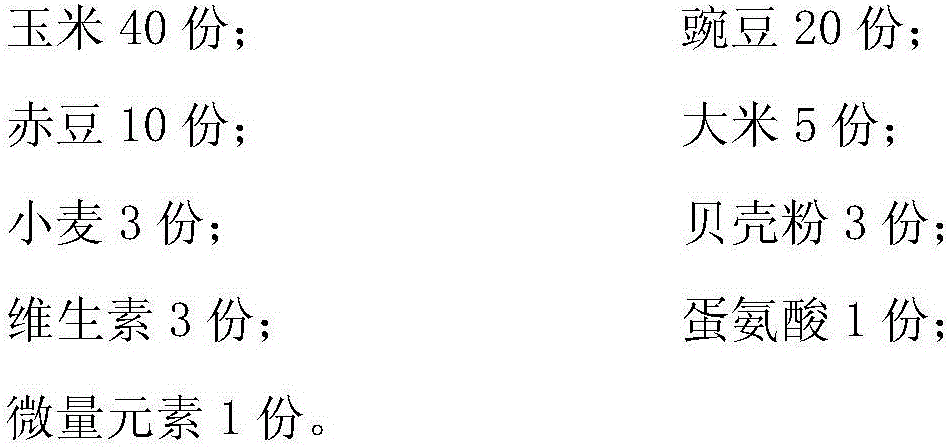

[0025] (1) In parts by weight, take the following and raw material components:

[0026]

[0027] (2) After the weighed raw material components are mixed evenly, the first additive can be obtained after low-temperature ultrafine grinding and sieving to 200 meshes, and is ready for use.

[0028] 2. Preparation of the second additive

[0029] (1) In parts by weight, take the following and raw material components:

[0030] 5 parts of Bacillus subtilis; 5 parts of Bacillus licheniformis;

[0031] 3 parts of Acetobacter; 1 part of Lactobacillus.

[0032] (2) After inoculating each strain that has been weighed in fermented liquid respectively and cultivating, each fermented liquid of gained is mixed uniformly, and after mixing with sterilized bran according to material-to-liquid ratio 1:1, carry out successively drying, Pulverize and sieve to 40 meshes to obtain the second additive, which is ready for use.

[0033] 3. Preparation ...

Embodiment 2

[0040] 1. Preparation of the first additive

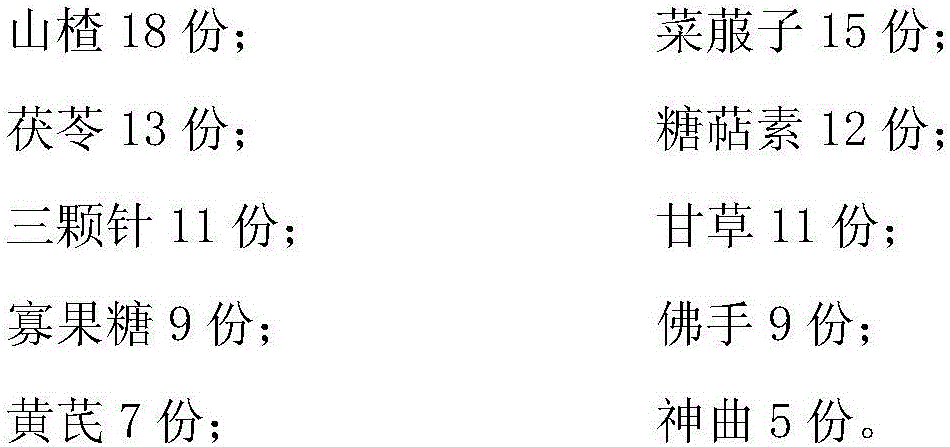

[0041] (1) In parts by weight, take the following and raw material components:

[0042]

[0043] (2) After the weighed raw material components are mixed evenly, the first additive can be obtained after low-temperature ultrafine grinding and sieving to 200 meshes, and is ready for use.

[0044] 2. Preparation of the second additive

[0045] (1) In parts by weight, take the following and raw material components:

[0046] 9 parts of Bacillus subtilis; 8 parts of Bacillus licheniformis;

[0047] 6 parts of Acetobacter; 3 parts of Lactobacillus.

[0048] (2) After inoculating each strain that has been weighed in fermented liquid respectively and cultivating, each fermented liquid of gained is mixed uniformly, and after mixing with sterilized bran according to material-to-liquid ratio 1:1, carry out successively drying, Pulverize and sieve to 40 meshes to obtain the second additive, which is ready for use.

[0049] 3. Preparation...

Embodiment 3

[0056] 1. Preparation of the first additive

[0057] (1) In parts by weight, take the following and raw material components:

[0058]

[0059] (2) After the weighed raw material components are mixed evenly, the first additive can be obtained after low-temperature ultrafine grinding and sieving to 200 meshes, and is ready for use.

[0060] 2. Preparation of the second additive

[0061] (1) In parts by weight, take the following and raw material components:

[0062] 12 parts of Bacillus subtilis; 10 parts of Bacillus licheniformis;

[0063] 8 parts of Acetobacter; 5 parts of Lactobacillus.

[0064] (2) After inoculating each strain that has been weighed in fermented liquid respectively and cultivating, each fermented liquid of gained is mixed uniformly, and after mixing with sterilized bran according to material-to-liquid ratio 1:1, carry out successively drying, Pulverize and sieve to 40 meshes to obtain the second additive, which is ready for use.

[0065] 3. Preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com