Pressurization cover beneficial to control of tea leaf rolling pressure

A technology of pressurizing lids and tea leaves, which is applied in the direction of tea processing before extraction, etc., can solve the problems of not being able to adjust the upper and lower positions of the pressurizing lids, and consuming the time and energy of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

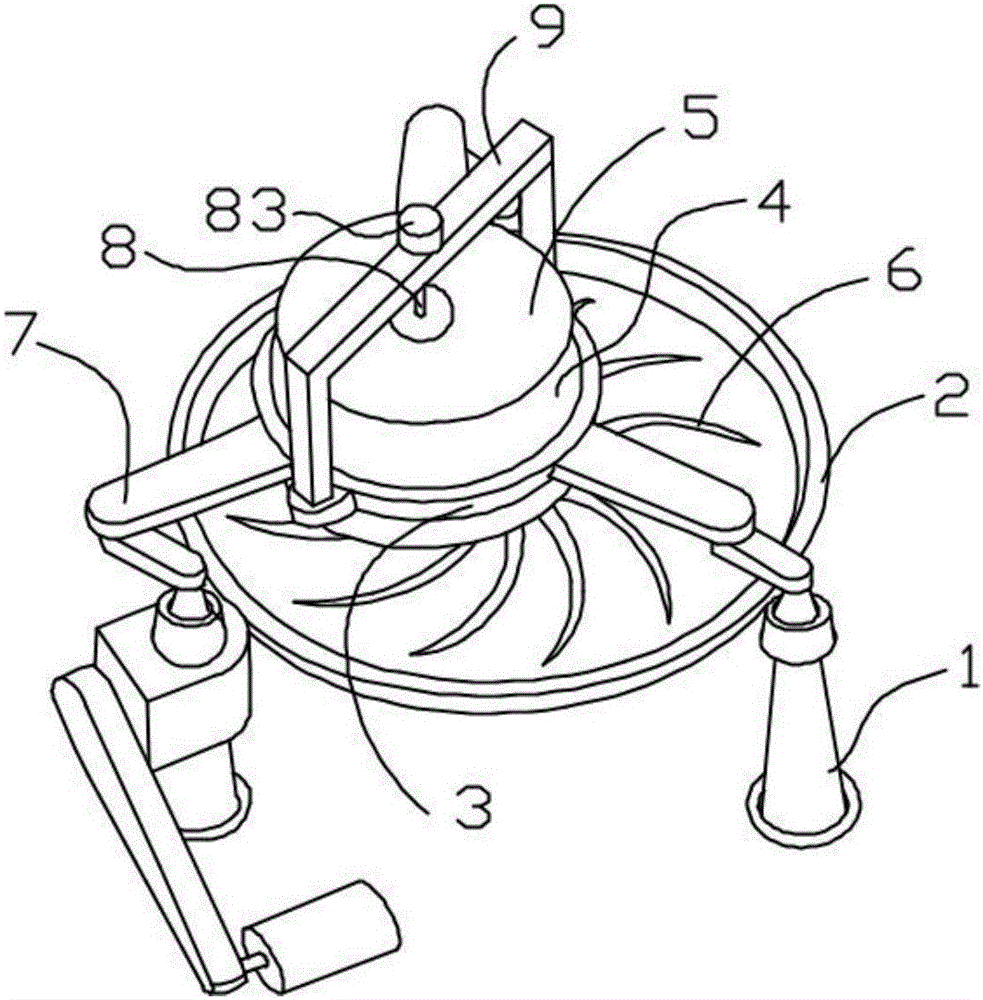

[0033] In the prior art, the kneading machine includes a support 1, a kneading disc 2 and a kneading device, the kneading device includes a kneading bracket 3, a kneading cylinder 4 and a pressure cover 5, the kneading disc 2 is fixed on the support 1, and the kneading disc 2 is provided with several The ribs 6 and the kneading bracket 3 are installed above the kneading disc 2 through the crank rocker mechanism 7, and the kneading cylinder 4 is fixed on the kneading bracket 3

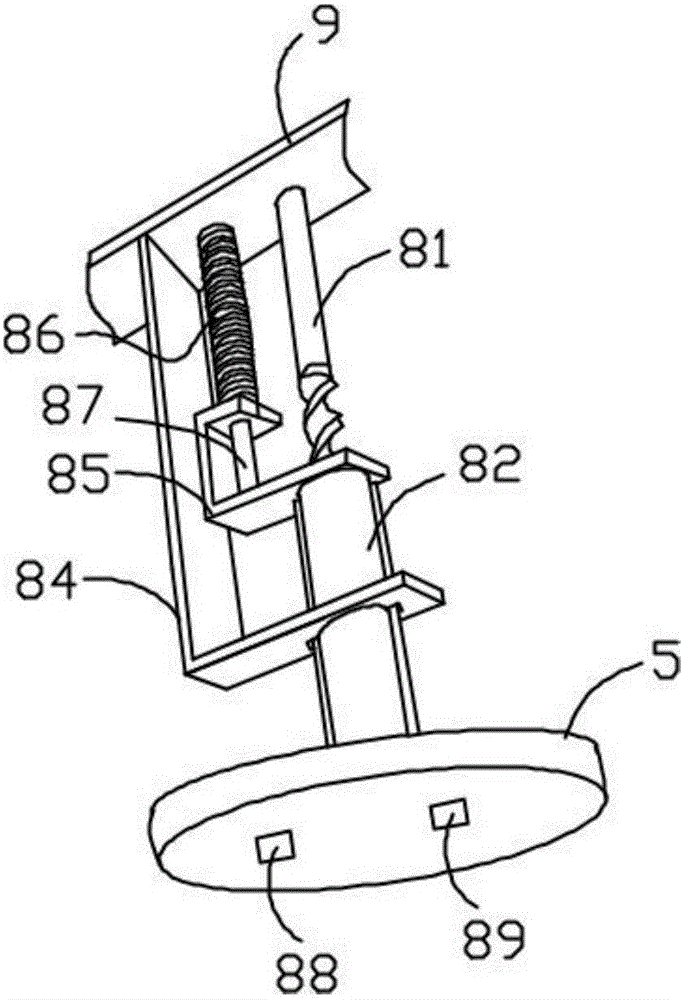

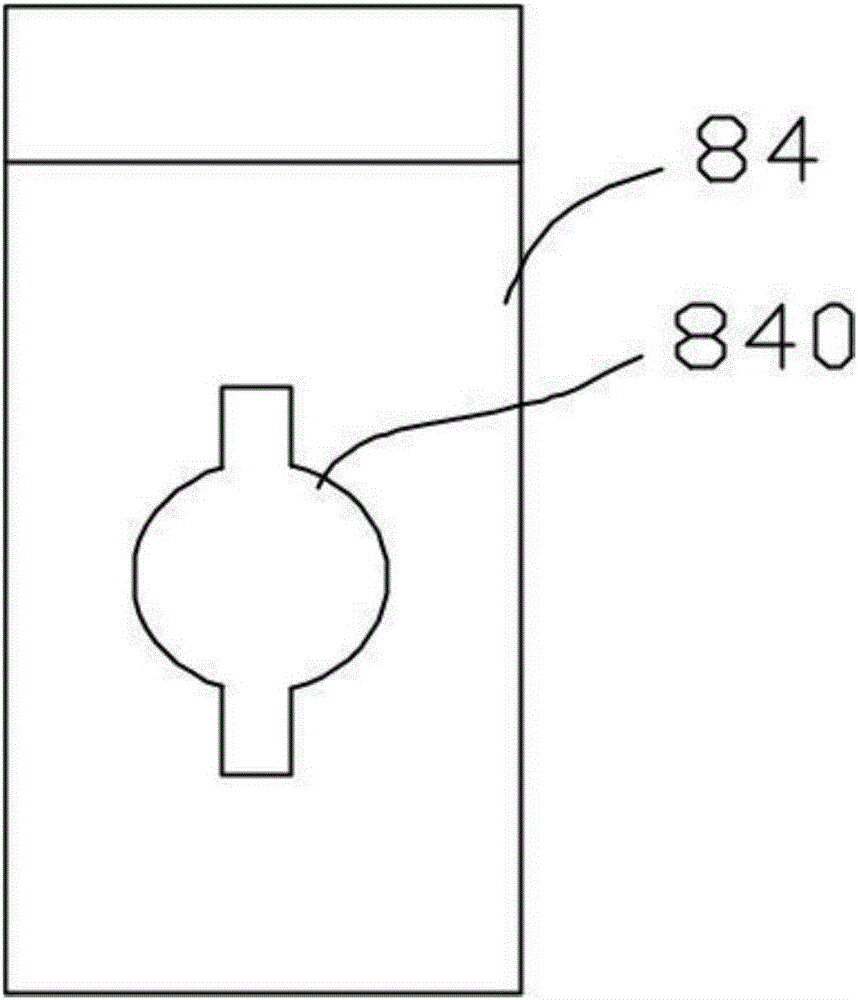

[0034] Such as Figure 1~3 As shown, the present invention is a pressurized cover that is beneficial to control the tea rolling pressure, including a pressure regulating device 8, and the pressure regulating device 8 is arranged above the rolling cylinder 4 through a fixing frame 9. The pressure regulating device 8 comprises a first adjusting rod 81 and a second adjusting rod 82, one end of the first adjusting rod 81 is arranged on the fixed frame 9 and is connected with the output end of the motor 83, ...

Embodiment 2

[0036] Further improvement on the basis of Embodiment 1, a second adjusting rod 82 of a pressure cover that is beneficial to control the tea rolling pressure is provided with a second fixing plate 85, and the plate surface of the second fixing plate 85 is in contact with the second adjusting rod 82. Vertically, the pressure regulating device also includes a spring 86, and the two ends of the axial direction of the spring 86 are respectively fixed on the fixed frame 9 and the second fixed plate 85 so that the spring 86 is fixed between the fixed frame (9) and the second fixed plate 85 . The second fixing plate 85 is also provided with a spring fixing post 87 for fixing the spring 86 .

Embodiment 3

[0038] Further improvement on the basis of Example 2, a pressurized cover that is beneficial to control the tea rolling pressure also includes a PLC controller; the cover surface of the pressurized cover 5 in contact with the tea leaves is provided with a pressure sensor 88, and the pressure sensor 88 is used for real-time Detect the pressure value received by the pressurized cover 5, and transmit the pressure value signal to the PLC controller; the PLC controller is used to receive the pressure value signal and send a start or stop control command to the motor 83; the pressurized cover 5 and the tea leaves A humidity sensor 89 is established on the contacted cover surface, and the humidity sensor 89 is used to detect the humidity value received on the lower surface of the pressure cover 5 in real time, and transmits the humidity value signal to the PLC controller; the PLC controller is used to receive the pressure value signal And send start or stop control instruction to moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com