Fruit and vegetable bactericide and production technique

A production process and technology of fungicides, applied in the direction of fungicides, biocides, biocides, etc., can solve the problems of crops that are prone to drug resistance, unfavorable for farmers to pick, and low control effect, so as to facilitate widespread popularization and use, prevent and control Remarkable effect, unique effect of the formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

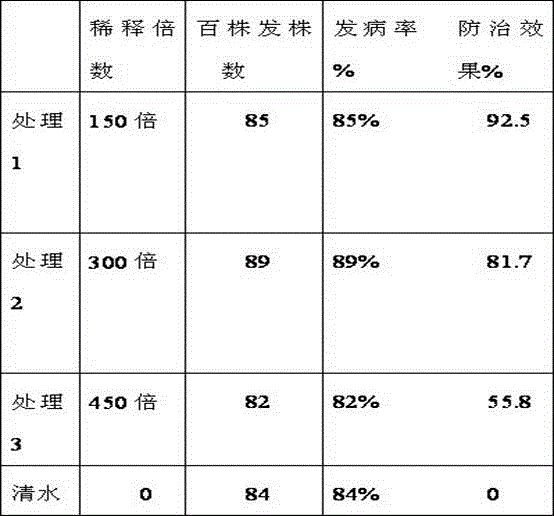

Image

Examples

Embodiment 1

[0016] Firstly, the vegetables and fruits are selected, washed, dried and weighed, and then a single variety of vegetables and fruits (such as purple onions) are crushed into fine powder. (Prickly ash and pepper are not crushed, they are soaked in 3 times of water for 6 hours and then boiled at 100 degrees for 30 minutes) Then extract: put the raw materials that are crushed into powder and boiled in water into a stainless steel extraction tank, for one ton The crushed fruit and vegetable raw materials are added to the natural wild jujube husk extract in a ratio of 1:3. The temperature was controlled at 35°C. For the first time, add 1200L of natural wild spinous jujube shell extract, control the temperature at 35°C, and extract for 72 hours; add 1000L of natural wild wild spinous jujube shell extract for the second time, control the temperature at 35°C, and extract for 48 hours; Add 800L of natural wild jujube husk extract to control the temperature and the extraction time is ...

Embodiment 2

[0021] First, select, wash, dry, and weigh vegetables and fruits, and then crush a single variety of vegetables and fruits (such as oranges) into fine powder, (including peppercorns and peppers that are not crushed, soak them in 3 times clear water for 6 hours, and then water Cook at 100 degrees for 30 minutes). Then extract: when extracting, put the crushed raw materials into a stainless steel extraction tank, and add natural wild jujube husk extract in a ratio of 1:3 to one ton of crushed fruit and vegetable raw materials. The temperature was controlled at 33°C. For the first time, add 1100L of natural wild spinous jujube shell extract, control the temperature at 33°C, and extract for 72 hours; add 1000L of natural wild wild spinous jujube shell extract for the second time, control the temperature at 33°C, and extract for 38 hours; Add 900L of natural wild jujube husk extract, the temperature is controlled at 30°C, and the extraction time is the same as the second time. St...

Embodiment 3

[0025] First, select, wash, dry, and weigh vegetables and fruits, and then crush a single variety of vegetables and fruits (such as: purple onion) into powder (including peppercorns and peppers that are not crushed, soak them in 3 times of clean water for 6 hours and then water them. Cook at 100 degrees for 30 minutes). Extraction is then carried out. During the extraction, the raw materials crushed into powder are put into a stainless steel extraction tank, and the natural wild jujube husk extract is added to a ton of crushed fruit and vegetable raw materials in a ratio of 1:3. The temperature was controlled at 30°C. For the first time, add 1300L of natural wild spinous jujube shell extract, control the temperature at 30°C, and extract for 72 hours; add 900L of natural wild wild spinous jujube shell extract for the second time, control the temperature at 30°C, and extract for 24 hours; Jujube husk extract 800L, temperature control time, leaching time are the same as the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com