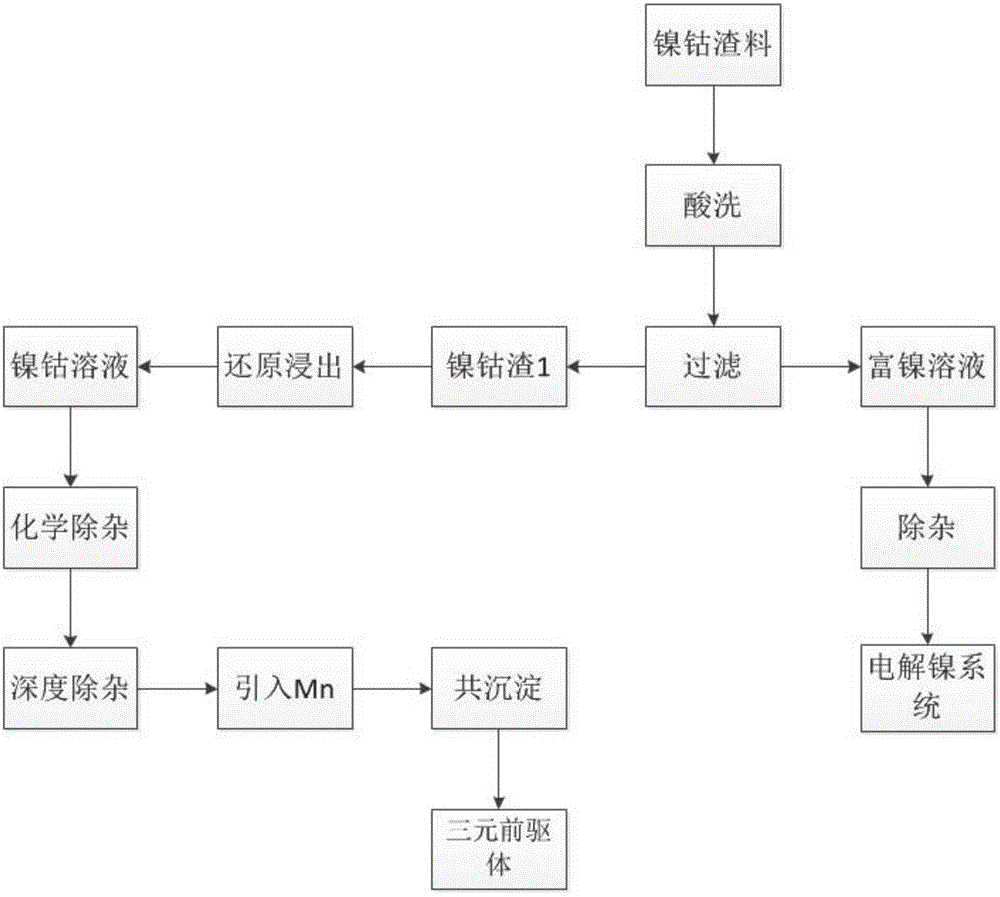

Method for preparing nickel-cobalt-manganese ternary material precursor by using nickel-cobalt slag material

A ternary material, nickel-cobalt-manganese technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of complex process and high cost, and achieve the effect of simple process, low cost, and realization of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The raw material nickel-cobalt slag used in this example is taken from the smelting slag produced by a non-ferrous smelter in Xinjiang (the ratio of nickel and cobalt in the nickel-cobalt slag is 40:7), and manganese sulfate is obtained through purchase.

[0051] Step (1): First wash the slag with deionized water to dissolve the nickel sulfate crystals dissolved in the slag, and then add 0.5mol / L of sulfuric acid with a liquid-solid ratio of 8mL / g (based on the weight of nickel-cobalt slag) , control the pH of the system to 2.5-3.0; and stir and react at 40-50°C for 2h. The solution after the acid leaching reaction is filtered, washed, dried, and ground to obtain nickel-cobalt acid leaching slag and nickel-rich solution (which can be returned to the electrolytic nickel system through chemical removal and deep extraction of the extractant or to prepare a high-nickel ternary precursor body); the nickel-cobalt ratio of the nickel-cobalt acid leaching residue material is 1:...

Embodiment 2

[0061] Compared with Example 1, the only difference is that in step (1), after adding the sulfuric acid solution, the pH of the control system is 1.0; and the reaction is stirred at 50° C. for 2 hours. The nickel-cobalt ratio of the nickel-cobalt acid leaching residue material is 0.87:1. In addition, step (3): Add manganese source solution to the extraction and purification solution, introduce a small amount of nickel-cobalt-manganese from the outside to make the molar ratio of nickel-cobalt-manganese 1:1:1, and then co-precipitate to prepare the precursor of the ternary cathode material . However, in the first low-acid leaching process, the nickel solution contains 1.5g / L of cobalt ions, which causes some troubles in the removal of impurities in the part of the solution that returns to the electrolytic nickel system.

Embodiment 3

[0063] Compared with Example 1, the only difference is that in step (1), after adding the sulfuric acid solution, the pH of the control system is 3.5; and the reaction is stirred at 50° C. for 2 hours. The nickel-cobalt ratio of the nickel-cobalt acid leaching residue material is 1.03:1. In addition, step (3): Add manganese source solution to the extraction and purification solution, introduce a small amount of nickel-cobalt-manganese from the outside to make the molar ratio of nickel-cobalt-manganese 1:1:1, and then co-precipitate to prepare the precursor of the ternary cathode material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com