Oil return preventing valve device for mechanical pump

A technology of mechanical pumps and oil valves, applied to mechanical equipment, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as glass stripping and waste products, and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

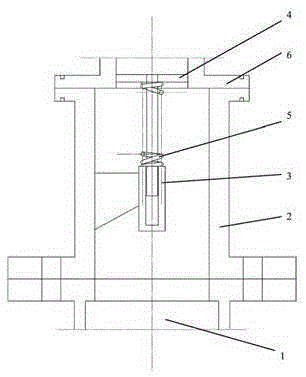

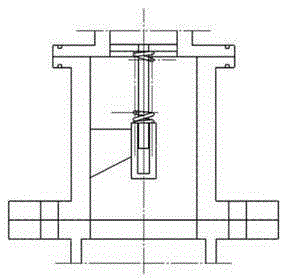

[0012] As shown in Figure 1, a mechanical pump anti-slip valve device according to the present invention includes a mechanical pump 1, an inlet cavity 2, a support mechanism 3, an anti-slip valve 4, a spring 5 and an inlet pipe 6.

[0013] The mechanical pump 1 and the inlet pipe 6 are connected through the inlet chamber 2, which is the function connection port of the mechanical pump anti-oil return valve device, and the inlet pipe 6 is arranged above the inlet chamber 2. The supporting mechanism 3 is fixed in the inlet cavity 2 and is a device supporting the reciprocating movement of the piston. The anti-slip valve 4 is connected with the support mechanism 3 through the spring 5, which is the core part of the whole device. The anti-slip valve 4 reciprocates on the support mechanism 3 under the action of the spring 5 through the pressure difference in the inlet cavity to realize The function of automatically isolating the pump chamber and the inlet pipe 6.

[0014] Working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com