Split type rigid protecting device

A fuse and split-type technology, applied in the field of mechanical presses, can solve the problems of high cost of use and long maintenance period of equipment, and achieve the effect of low cost of use and short maintenance period of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

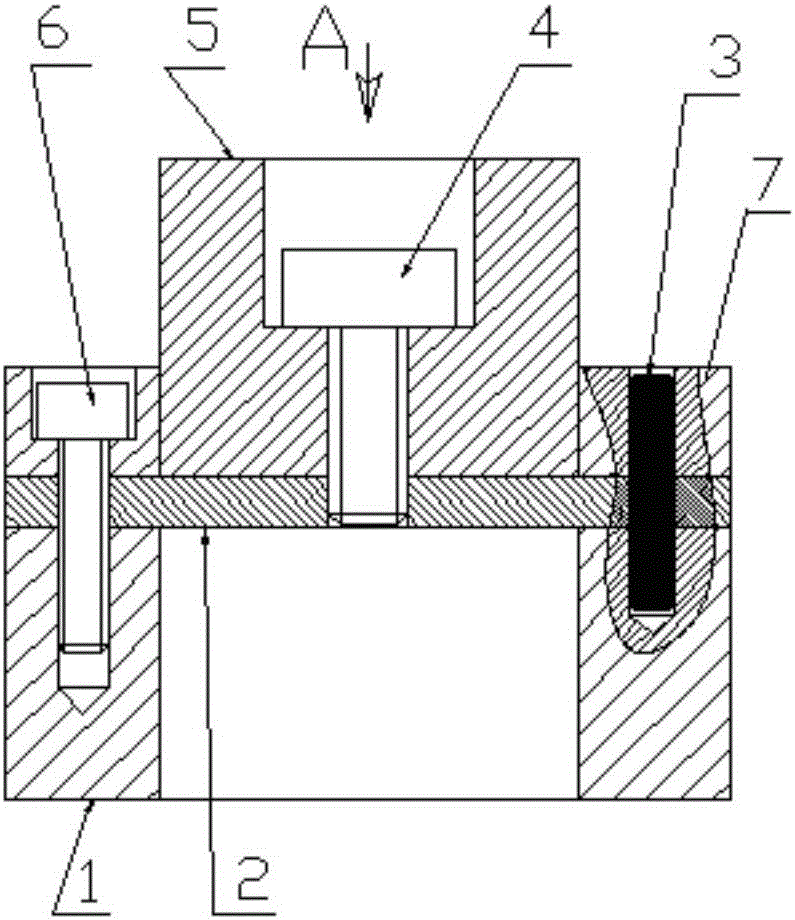

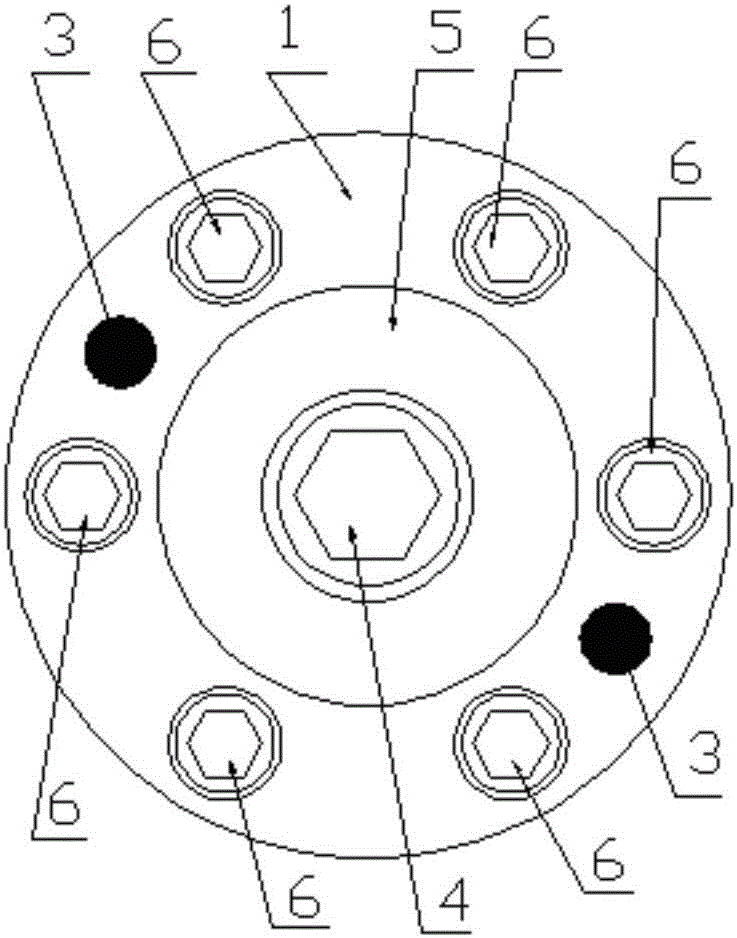

[0009] A split type rigid fuse, which is composed of: base (1), fuse (2), positioning pin (3), positioning bolt (4), indenter (5), fastening bolt (6), positioning and The guide ring (7) is composed of the base (1) is made of medium carbon steel after quenching or made of die steel, the indenter (5) is made of medium carbon steel after quenching or made of die steel, and the safety disc (2) Directly made of ordinary low-carbon steel, the upper part of the base (1) is provided with a fuse (2) and a positioning and guide ring (7), the base (1) and the fuse (2), and a positioning and guide ring (7). ) The positioning pin (3) and the fastening bolt (6) are connected and fixed into one body. There is a through hole in the middle of the positioning and guide ring (7). A pressure head (5) is provided in the middle through hole of the positioning and guide ring (7). ), the indenter (5) is integrated with the safety disc (2) by the positioning bolt (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com