Laundry-treatment appliance having a feeding device

A technology for clothing processing and supplying devices, applied in washing devices, household appliances, other washing machines, etc., can solve problems such as water and energy consumption, and achieve the effects of reducing water and energy consumption, reducing residual moisture, and reducing residual moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

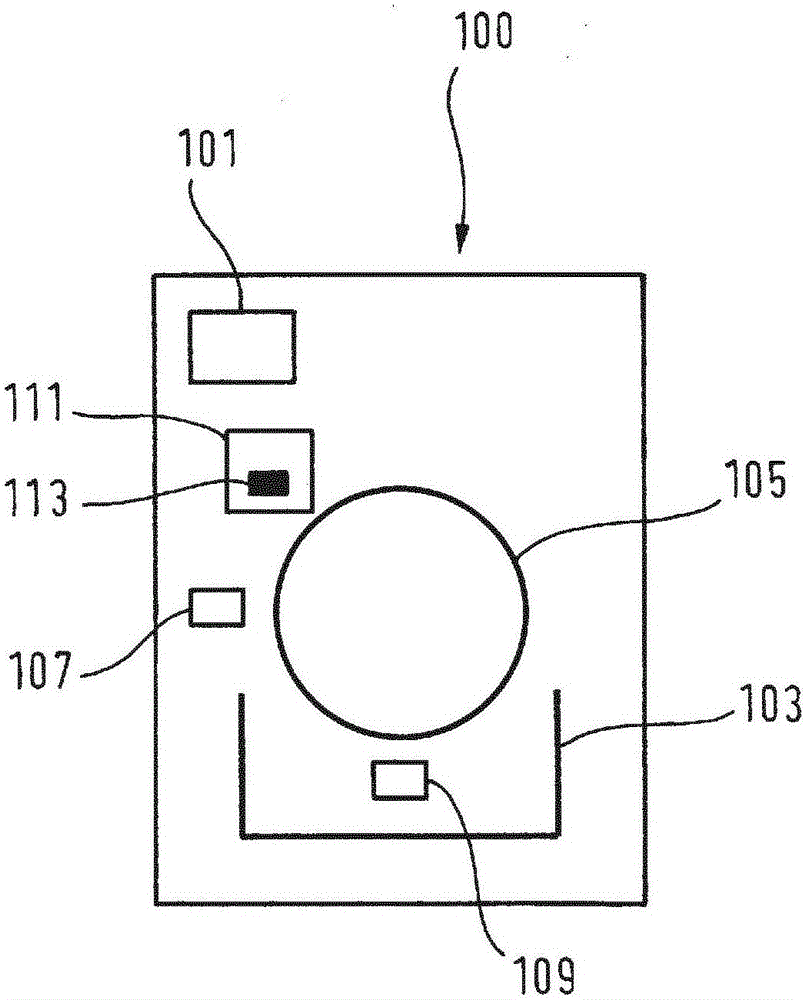

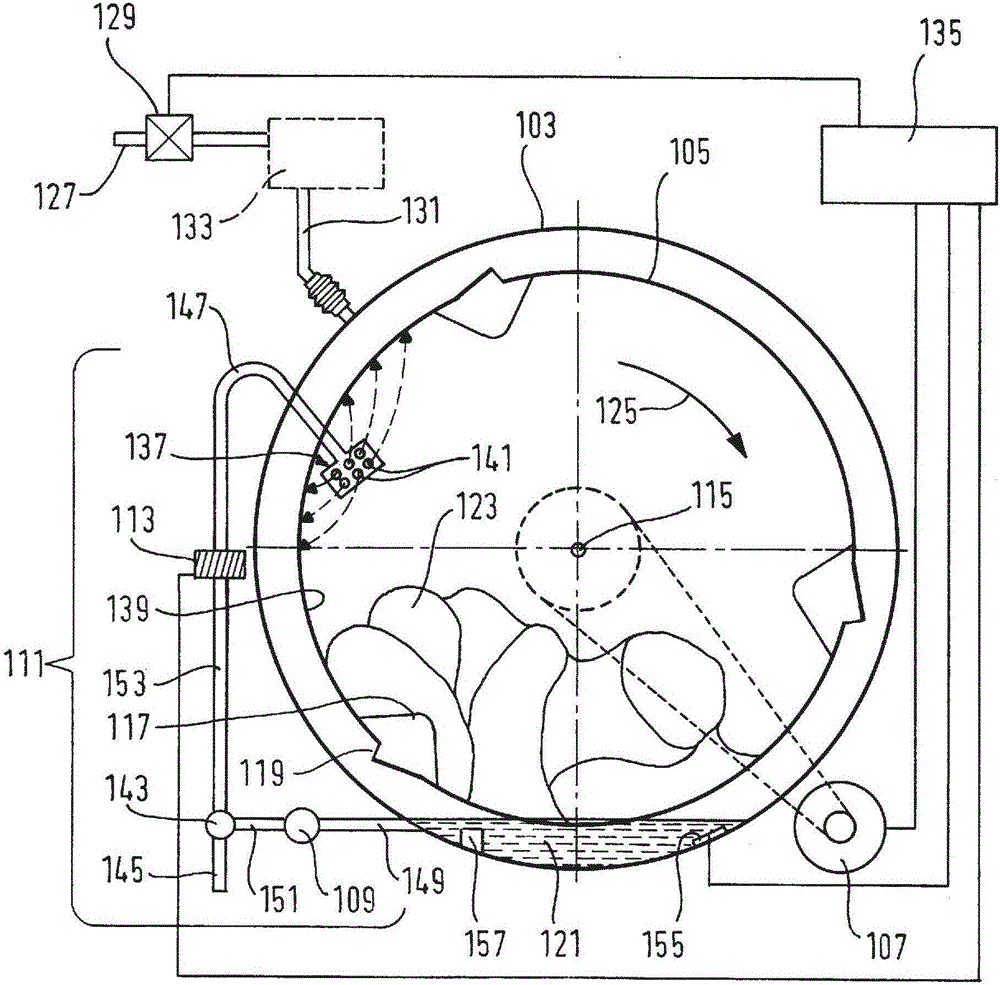

[0050] figure 1 A schematic diagram of a general laundry treating appliance 100, such as a washing machine, is shown. The laundry treating appliance 100 includes a storage container 101 into which detergent and other liquid substances can be introduced. When water is supplied into the storage container 101 and mixed there with detergent or other liquid substances, washing liquid required for the laundry treatment process is generated. The laundry treating appliance 100 part includes a tub 103 in which generated washing liquid is accommodated. A quantity of laundry can be introduced into the rotatably mounted washing drum 105 , at least a part of the washing liquid being guided into the tub 103 . The laundry treating appliance 100 comprises a drive 107 which drives the washing drum 105 and thereby enables the washing drum 105 to rotate.

[0051] The discharge pump 109 is configured to pump the washing liquid from the tub 103 and supply the washing liquid to the laundry in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com