Buffering and vibration isolation structure of annular circuit board

A ring-shaped buffer and ring-shaped structure technology, applied in electrical components, electrical equipment enclosures/cabinets/drawers, etc., can solve the problems of circuit board damage and failure, circuit board multi-point installation layout, circuit board excitation amplification, large installation space, etc. Save installation time, strong structural scalability, and prevent failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

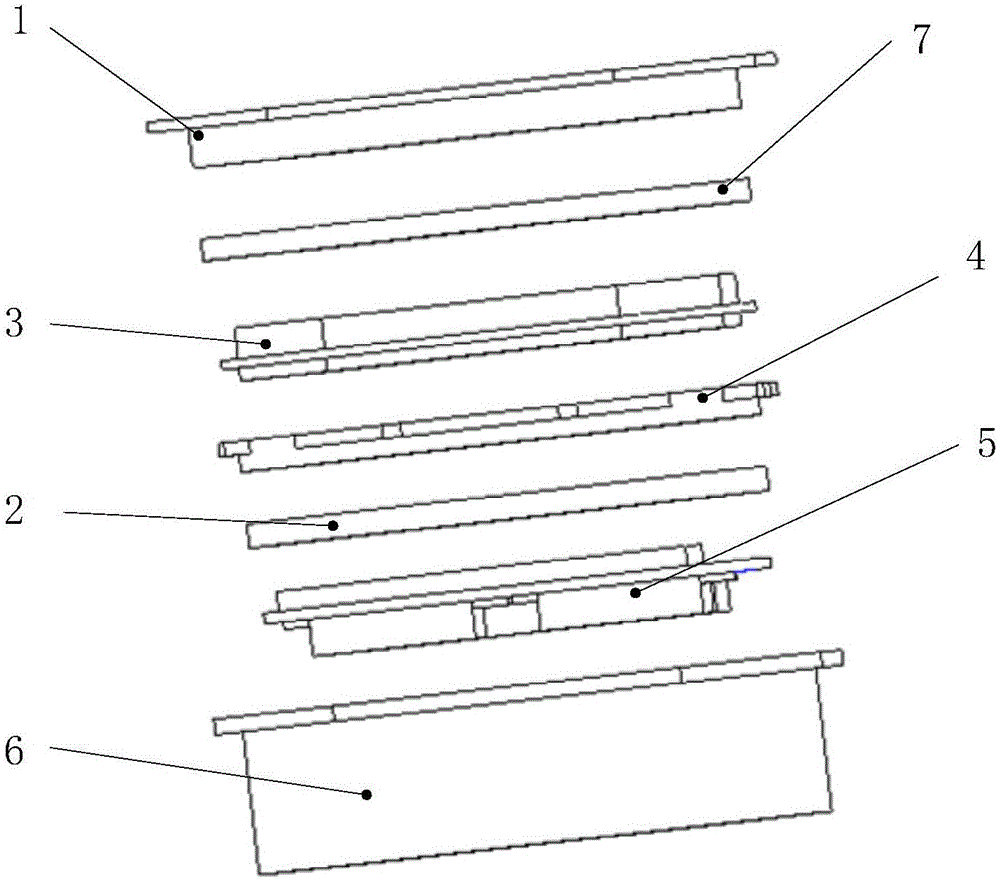

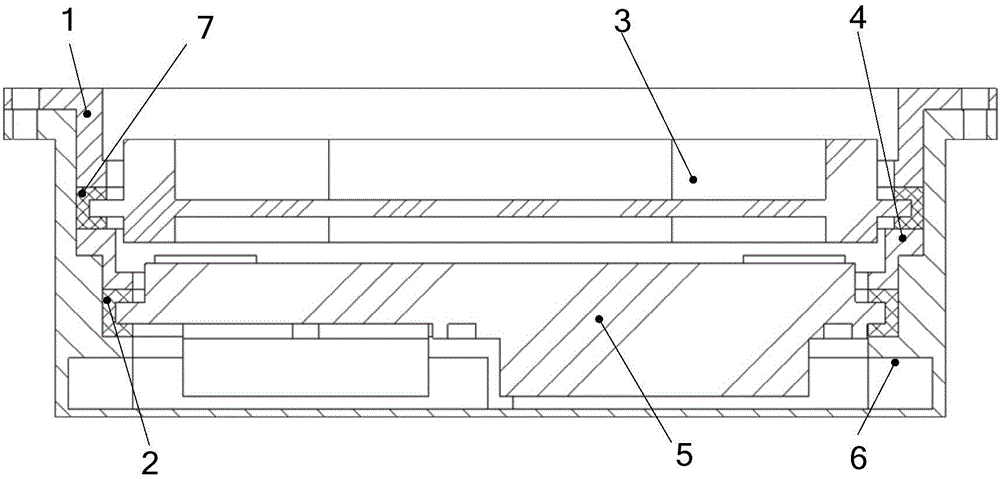

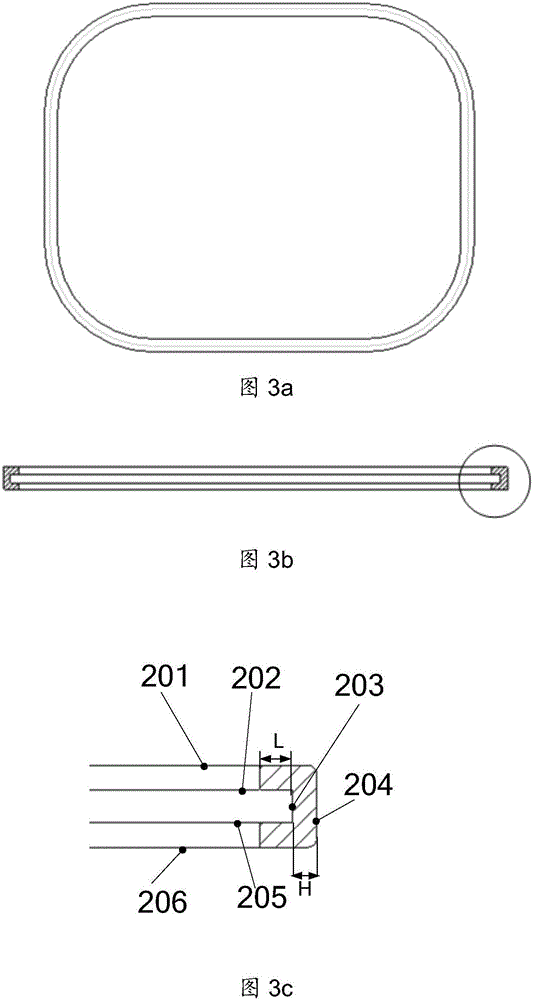

[0032] The circuit board annular buffer vibration isolation structure of the present invention can install a plurality of circuit boards, and the buffer vibration isolation structure specifically includes n baffles, n rubber rings and a box base, where the first circuit board is embedded with the first rubber ring around, Placed on the first step of the box base, the first baffle is fixedly connected to the second step of the box base, and the lower surface of the first baffle presses the first rubber ring, and the second circuit board is embedded around the second After the rubber ring, it is placed on the upper surface of the first baffle, and the second baffle is fixedly connected to the third step of the box base, and the lower surface of the second baffle presses the second rubber ring, and the third circuit board is surrounded by After emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com