A fully automatic lamination device for a Japanese-shaped or e1-shaped iron core of a transformer

A lamination device and transformer technology, applied in the manufacture of inductors/transformers/magnets, electrical components, manipulators, etc., can solve the problems of frequent boring repetitive actions, unstable product quality, low production efficiency, etc., and achieve compact structure and easy maintenance. Low cost and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

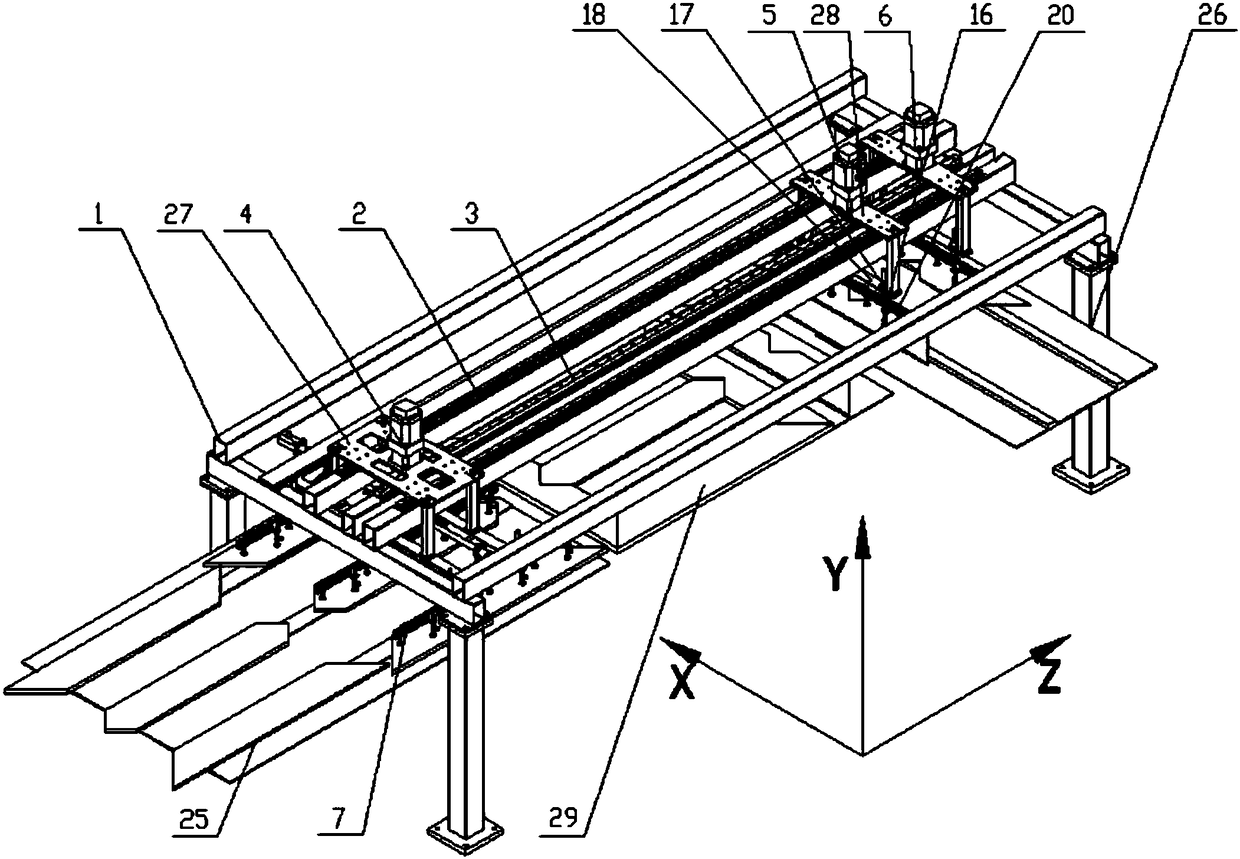

[0025] Such as figure 1 As shown, a fully automatic lamination device for a Japanese-shaped or E1 iron core of a transformer includes at least a lamination frame 1, a guide rail device 2 and a helical rack 3 that are fixed above the lamination frame 1 and arranged parallel to each other, and are installed along the guide rail. 2 and the three-column stack 4, the yoke column stack 5 and the upper yoke column stack 6 that move with the helical rack 3, the three-column stack 4, the yoke column stack 5 and the upper yoke column stack 6 are on the same straight line and They are respectively connected to the guide rail device 2, and the three-post stack 4, the yoke post stack 5 and the upper yoke post stack 6 are respectively driven by a set of servo system and helical gear 28, and the servo system includes a servo motor and a The reducer connected to the servo motor, the reducer is fixed on the servo connecting plate 27 and connected with the helical gear 28 through a tensioner sl...

Embodiment 2

[0029] On the basis of Embodiment 1, the guide rail device 2 is composed of two parallel linear guide rail pairs, and the helical rack 3 is arranged between the two linear guide rail pairs.

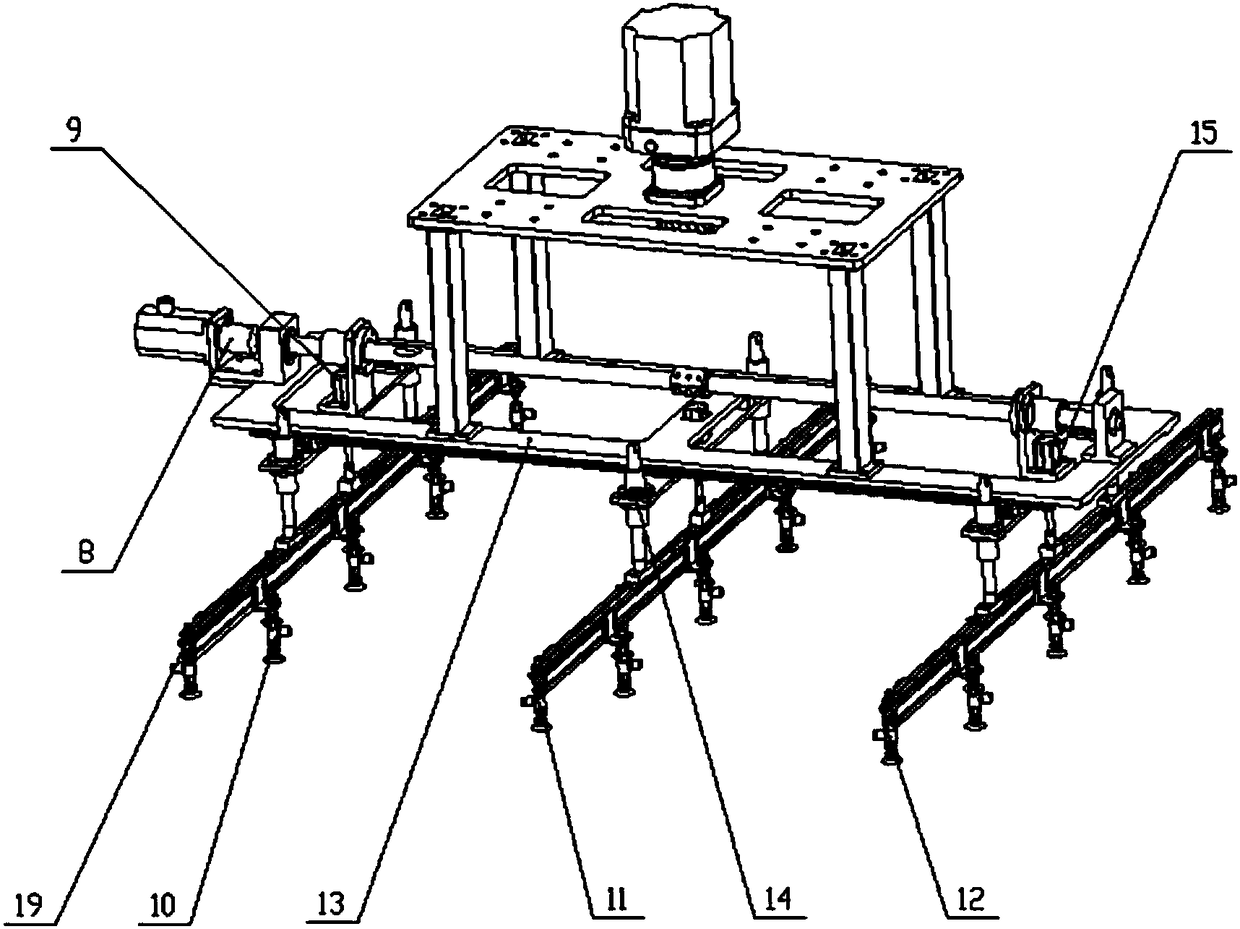

[0030] Such as figure 2 As shown, the three-column stacking 4 includes a three-column connecting plate 13, three sets of vacuum manipulators 7, a transmission device 8 for controlling the three sets of vacuum manipulators 7 to expand and contract in the X direction, and a first pneumatic device 9 to expand and contract in the Y direction. The device 9 is provided with three groups, and the three groups of vacuum manipulators 7 include the first vacuum manipulator 10, the second vacuum manipulator 11 and the third vacuum manipulator 12 parallel to each other, the first vacuum manipulator 10, the second vacuum manipulator 11 and the third vacuum manipulator 10. The vacuum manipulators 12 are respectively connected to a group of first pneumatic devices 9 through the first beam 19, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com