Container inner wall adhesion quality nondestructive detection method based on shearing speckle interferometry

A bonding quality and non-destructive testing technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as the inability to detect the bonding quality of the inner wall of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

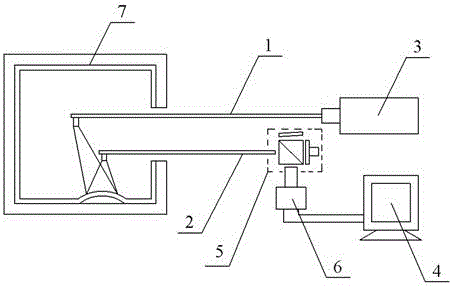

[0023] Embodiment 1: This non-destructive inspection method for the adhesion quality of the inner wall of a container based on shear speckle interference, the operation steps are as follows:

[0024] 1) First, transmit the laser light emitted by the single-mode laser (3) to the inside of the container (7) through a polarization-maintaining single-mode light guide fiber (1), and illuminate the area to be measured after uniformly expanding the beam;

[0025] 2) Use an imaging fiber bundle (2), put it into the container (7), and install an imaging lens at the inner end of the imaging fiber bundle container to transmit the speckle image of the area to be measured to the other end of the fiber bundle outside the container;

[0026] 3) Using the Michelson interference optical path, the speckle image of the area to be measured transmitted through the imaging fiber bundle in step 2) forms a pair of misaligned images after passing through the Michelson optical path. The speckle interference im...

Embodiment 2

[0029] Example 2: Reference figure 1 with figure 2 This embodiment is basically the same as the first embodiment, and the special features are as follows:

[0030] The step 1) is to use a polarization-maintaining single-mode light-guiding fiber (1) to transmit the single longitudinal mode laser beam to the inside of the container (7) under the condition that the laser polarization remains unchanged. The light outlet of the light guide optical fiber (1) is equipped with a beam expander to uniformly expand the laser beam and illuminate the area to be measured.

[0031] The step 2) is to introduce an imaging fiber bundle (2), the front end of the fiber bundle is equipped with a conventional optical lens, according to the actual engineering working distance and detection area needs to select a suitable lens, and extend the end to the container (7) Internal; adjust the lens position to aim at the area to be measured, and adjust the focal length and aperture of the lens at the same tim...

Embodiment 3

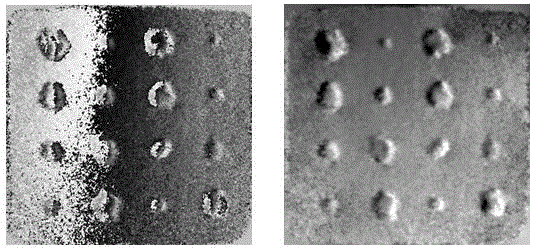

[0036] figure 1 It is a schematic diagram of the optical path arrangement of the non-destructive inspection method for the adhesion quality of the inner wall of the container based on the shear speckle interference. According to the schematic diagram, the shearing speckle system based on the imaging fiber bundle is arranged and used to test the aluminum skin aluminum honeycomb panel with built-in debonding defects. The detection process is:

[0037] 1) First, the aluminum skin aluminum honeycomb panel is firmly fixed on the optical platform through the magnetic table base to minimize the impact of external vibration on the test results;

[0038] 2) Introduce a single longitudinal mode laser with a polarization-maintaining light-guide fiber (1), and the laser beam is transmitted through the light-guide fiber (1) and expanded uniformly through a front-end beam expander to illuminate the aluminum skin aluminum honeycomb panel;

[0039] 3) Assemble an optical lens with a focal length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com