Apparatus suitable for measuring bending rigidity, elasticity modulus, shear modulus and bulk modulus

A technology of elastic modulus and shear modulus, applied in the field of elastic modulus, devices that can measure bending stiffness, shear modulus, and bulk modulus, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

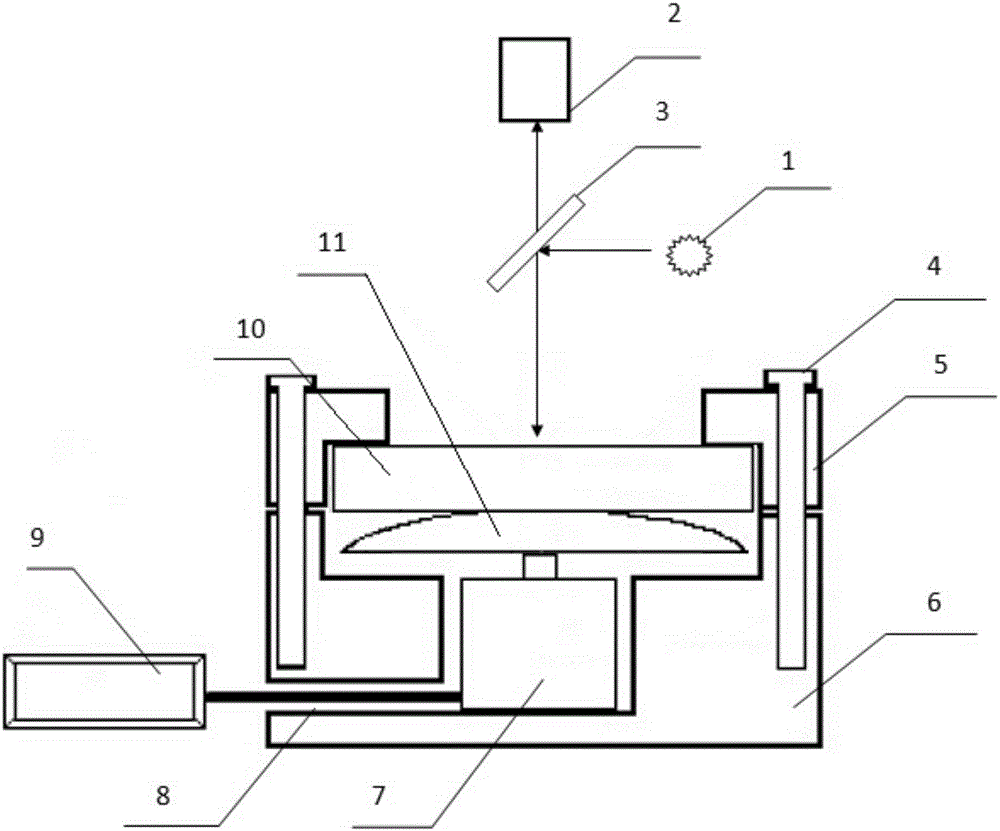

[0014] The present invention can measure the device of bending stiffness, elastic modulus, shear modulus and bulk modulus, the structure is as figure 1 As shown, including the base 6, the stress sensor 7 is placed in the groove of the base 6, the probe of the stress sensor 7 is higher than the upper surface of the groove of the base 6, a plano-convex lens 11 is placed on the probe of the stress sensor 7, and a plano-convex lens 11 is placed on the probe of the stress sensor 7. An optical flat glass 10 is placed, and the convex surface of the plano-convex lens 11 is in contact with the optical flat glass 10. On the edge of the upper surface of the optical flat glass 10, a loam cake 5 is placed, and the loam cake 5 is connected with the base 6 by a set screw 4. The loam cake 5 is connected with the base 6. There is a gap between the bases 6 ; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com