Variable Mach number nozzle mechanism having large-stroke range and high precision

A high-precision, large-stroke technology, applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of lack of research on high-precision adjustment mechanisms, and achieve simple structure, guaranteed airflow quality, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

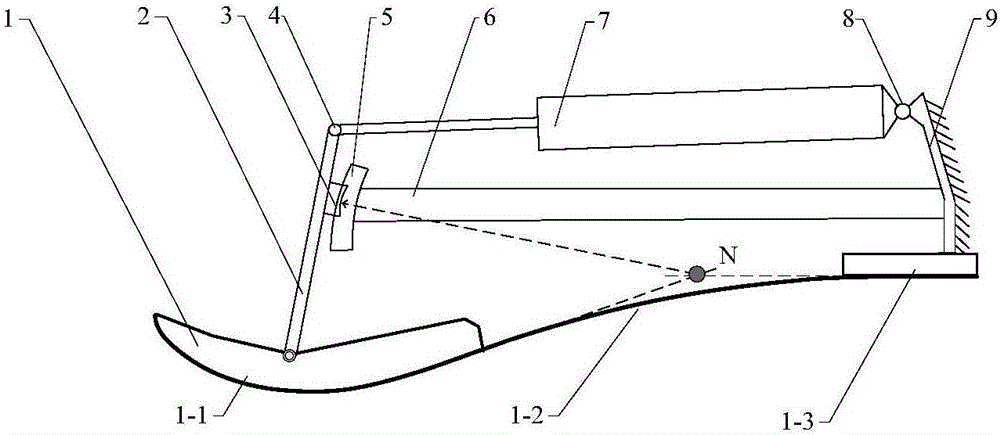

[0017] The working process of the nozzle is as follows: the roller screw electric cylinder 7 drives the rotating support plate 2 to move; the rotating support plate 2 rotates precisely along the rotation center N under the action of the arc rolling slider 3 and the smooth guide rail 5 ; The fixed profile section 1-1 of the rigid-flexible coupling profile 1 rotates with the rotating support plate 2, and drives the flexible profile section 1-2 to deform around the rotation center N, and the straight section 1-3 at the outlet remains basically unchanged, Therefore, the throat height adjustment of the profile mechanism is realized, and the Mach number adjustment of the nozzle outlet is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com