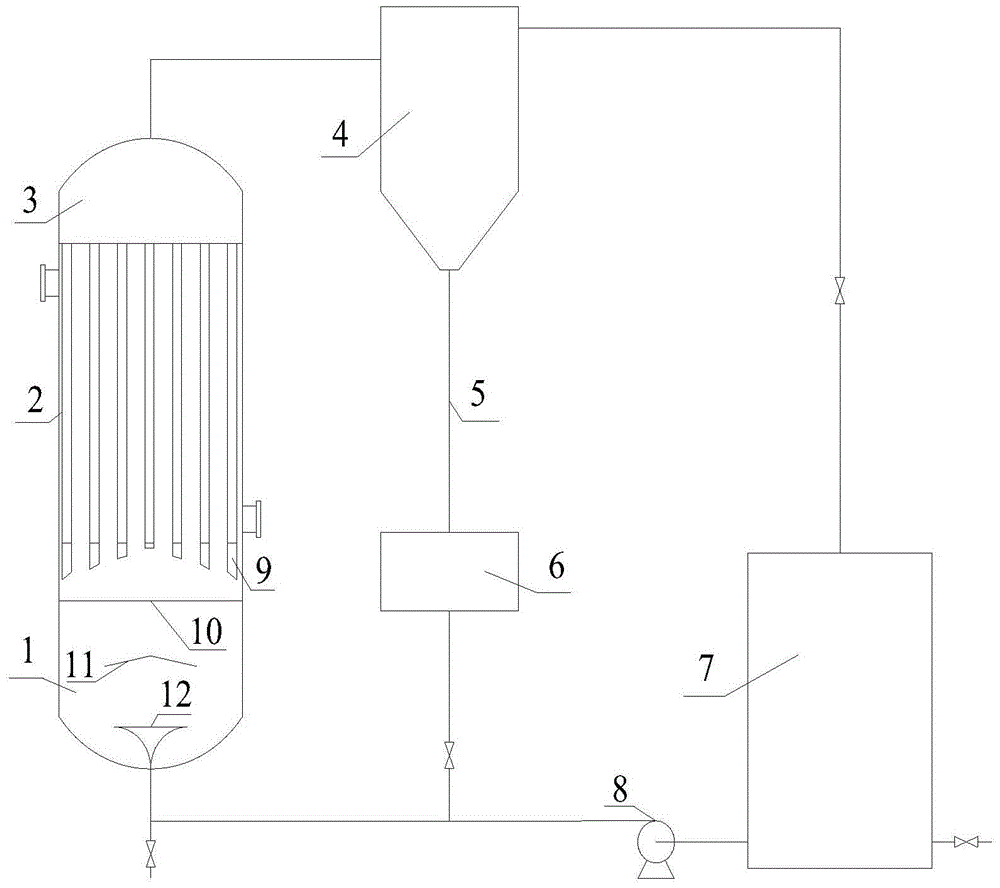

Outer circulating fluidized bed heat exchanger

A fluidized bed heat exchanger and external circulation technology, which can be applied to heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of easy scaling of heat exchangers and decreased heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

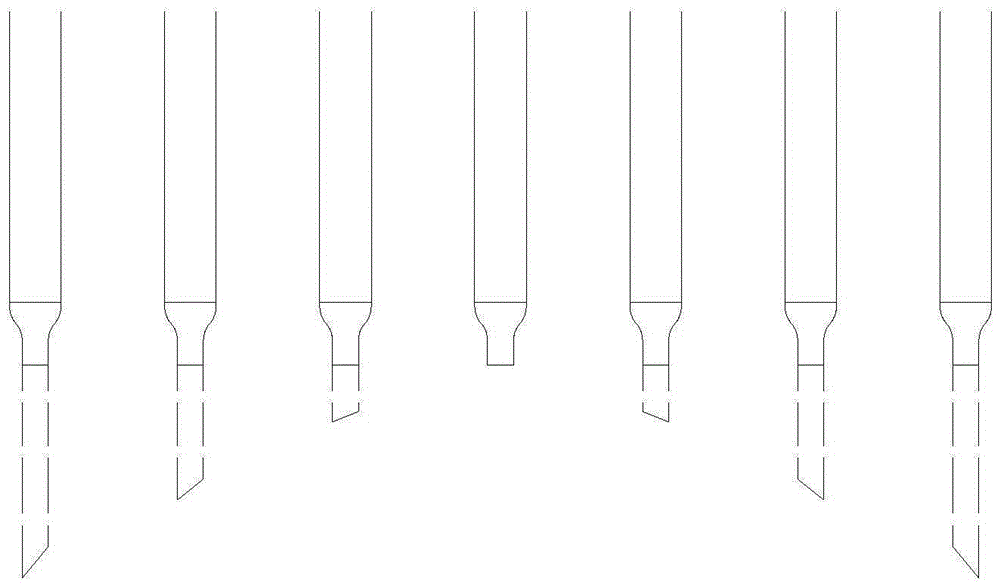

[0032] use figure 1The external circulating fluidized bed heat exchanger shown is applied to the reaction effluent / mixed feed heat exchanger of a reforming hydrogenation unit. The external circulating fluidized bed heat exchanger is equipped with 442 heat exchanger tubes. Each tube is 8000mm long, with a diameter of Φ22×1.5mm, and the tubes are arranged in an equilateral triangle. The solid particles are glass beads with an average particle diameter of 5 mm, and the average volume solid content of the solid particles in the external circulating fluidized bed heat exchanger is 3%. The liquid phase is diesel oil with a flow velocity of 1.5m / s. The diameter of the lower casing is 12mm, and the arrangement is as follows: one in the middle, with a length of 15mm, no bevel and no opening; a total of 183 in the middle 7 layers, a length of 20mm, a bevel of 60 degrees, and a hole with a diameter of 1.2 times the average particle size of solid particles, a total of 258 in the outer 4...

Embodiment 2

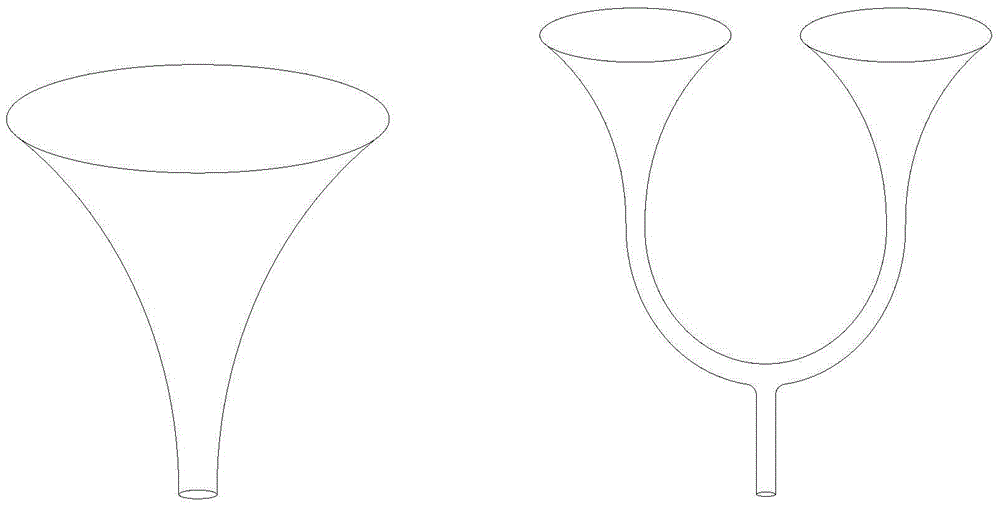

[0034] The same external circulating fluidized bed heat exchanger as in Example 1 is applied to the reaction effluent / mixed feed heat exchanger of a reforming hydrogenation unit, and the solid particles are glass beads with an average particle diameter of 2 mm. The average volume solid content in the circulating fluidized bed heat exchanger is 8%. The liquid phase is diesel oil, and the flow rate is 4m / s. The diameter of the casing along the lower edge is 7.5mm, and the arrangement is as follows: one in the middle, length 20mm, no groove, no opening; 183 casings in the middle 7 layers, length 30mm, groove 30 degrees, one hole, aperture It is 1.5 times the average particle size of solid particles. There are 258 pieces in the outer 4 layers, the length is 50mm, the bevel is 15 degrees, and two holes are opened. The hole diameter is 1.2 times the average particle size of solid particles. The entrance of the down tube box is a horn tube with a single opening, the sum of the outle...

Embodiment 3

[0036] The same external circulating fluidized bed heat exchanger as in Example 1 is applied to the reaction effluent / mixed feed heat exchanger of a reforming hydrogenation unit, and the solid particles adopt aluminum oxide beads with an average particle diameter of 5mm. The average volume solid content in the external circulating fluidized bed heat exchanger is 3%. The liquid phase is diesel oil with a flow velocity of 1.5m / s. The diameter of the lower casing is 12mm, and the arrangement is as follows: one in the middle, with a length of 15mm, no bevel and no opening; a total of 183 in the middle 7 layers, a length of 20mm, a bevel of 60 degrees, and a hole with a diameter of 1.2 times the average particle size of solid particles, a total of 258 pieces in the outer 4 layers, the length is 30mm, the bevel is 30 degrees, and a hole is opened, the hole diameter is 1.2 times the average particle size of solid particles. The entrance of the down tube box is a horn tube with three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com